Our objective is to cover the shut-in procedures for a surface BOP Stack in case of well control issues & to cover A.P.I. recommendations for these procedures, which include advantages and disadvantages.

When any positive indications of a kick (also check: Kick warning signs) are observed and a check shows that the well is flowing, it should be shut in immediately. However, If surface casing (check also: Types of casing in drilling) alone has been set, the flow should be diverted rather than attempting a shut-in which might endanger the rig. Diverter well control procedures are discussed in the Diverter Drilling System article.

Where a good casing seat (check also: casing setting depth) exists, it cannot be over-emphasized that early detection and early shut-in of well kicks minimizes the hazards (Oil Rig Hazards) and simplifies the killing process.

If there is doubt as to whether or not the well is flowing, the safest policy is to shut in and check pressures. A small flow can rapidly turn into a full flow and blow out. Occasionally, fear of stuck pipes has caused hesitation in shutting in wells. In general, stuck pipe problems are minimized by closing in the well early, with a small influx to remove and lower the wellbore pressures being exerted.

The possibility of breaking down the formation – especially at the shoe may also cause hesitation in shutting the well in. Here, if the well is allowed to flow, it will eventually be necessary to shut it in, with higher pressures and a greater likelihood of causing damage.

Shut In Procedures In Well Control Guidelines.

- The shut-in procedure should be agreed upon by the contractor and operating company and posted on the rig floor before drilling the well begins.

- When there is any positive indication of a kick, such as a sudden increase in flow or pit level, the well should be shut in immediately without doing a flow check.

- If the increase in flow or pit gain is hard to detect, then a flow check can be done to confirm the well is flowing.

- If the surface hole is drilled, the conductor casing pipe is not set in a competent formation, and a shallow gas kick is taken, then the gas should be diverted. This will be discussed at the end of this section.

- The shut-in procedures that follow are generalized suggestions and not necessarily applicable to any specific rig in case of well control.

- For floating Rigs, Obtaining an accurate flow check by observing the flow line on the rig floor or the shale shaker may be challenging due to rig movement.

- To obtain an accurate flow check in floating offshore rigs:

- If the surface hole is being drilled and the conductor or surface casing is not set in a competent formation, and a shallow gas kick is taken, then the kick should be diverted and not shut in. (also check: Diverteing procedures for well control)

Shut In Well While Drilling Methods:

There are mainly 2 API methods for shut-in for well control issues that are:

- Soft Shut In Procedures for well control

- Hard Shut In Procedure

Also, there is still one non-API method which is fast shut-in. Its procedure is as follows:

- When any indication is observed while drilling that the well may be flowing, stop rotating the drill string, and raise the drill string with pumps on until the tool joint is above the drill floor.

- Stop pumps and check for flow, if positive:

- Open choke line HCR valve.

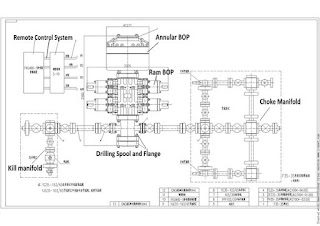

- Close Annular BOP.

- Call rig drilling supervisors and plot a shut-in drill pipe pressure graph. Check pit volume gain.

Note: There are no A.P.I recommendations for the fast shut-in

Soft Vs. Hard Shut In Procedure For Well Control

The soft close-in procedure provides a means of monitoring casing pressure and more sensitive control of casing pressure buildup during closure than will be experienced using the hard close-in procedure. If the initial closed-in casing pressure is likely to exceed the maximum allowable casing pressure, the soft close-in procedure permits initiation of a low choke pressure procedure or other alternate procedures before the maximum allowable casing pressure is reached. In this situation, the soft close-in procedure has a distinct advantage over the hard close-in procedure.

The major disadvantage of the soft close-in procedure is that the additional time involved in opening the choke line valve and closing the choke will allow additional influx into the wellbore. This procedure will result in a larger kick volume and potentially higher casing pressure than obtained if the hard close-in procedure is used while circulating out the kick.

The hard close-in procedure is somewhat less complicated, can be performed by one man working on the rig floor, and is more likely to be performed without inadvertent delays in closure than the soft close-in procedure.