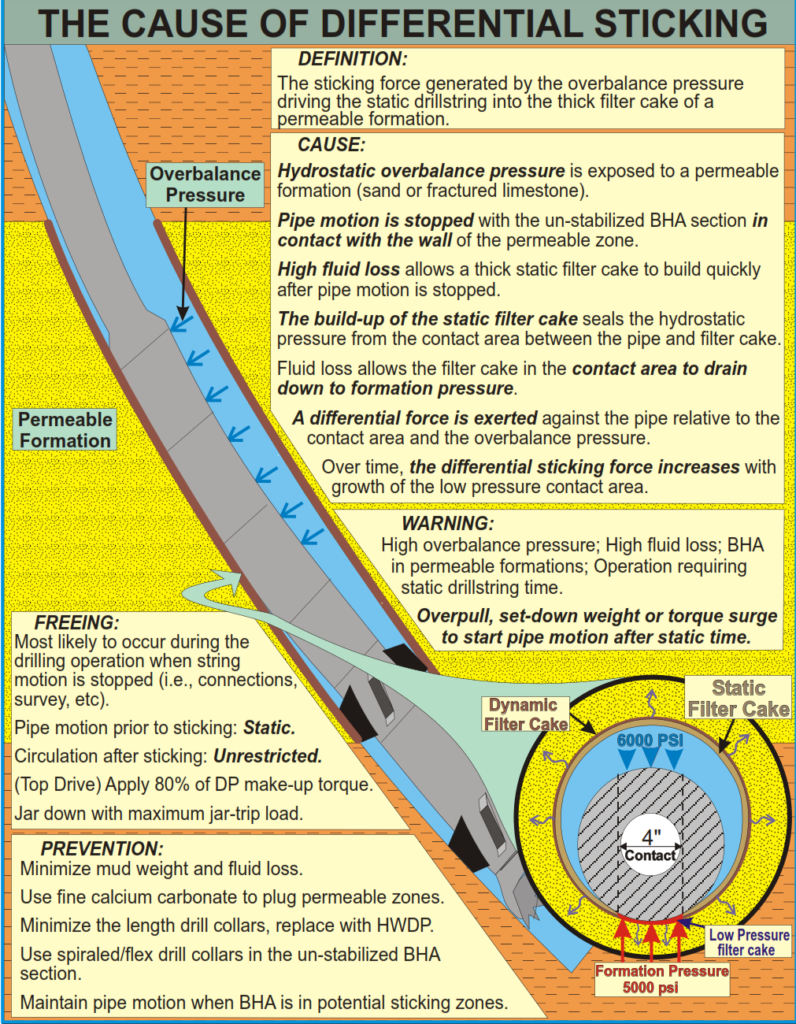

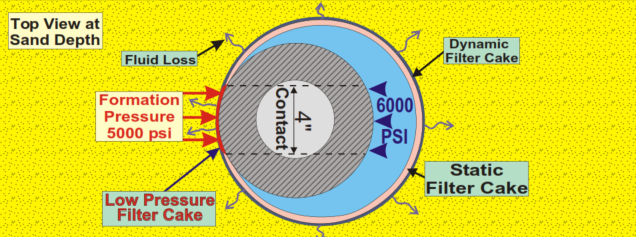

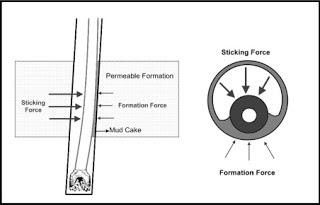

In general, differential sticking is a situation that may happen during any stage of drilling the well and cause the drill string or casing pipe to be stuck (no upward or downward movement). It actually happens when the hydrostatic pressure, ph (which acts on the outside wall of the Pipe), is more than the pore pressure, pf (which leads to forcing the pipe into the mud cake).

This situation can happen on a Drill Pipe, Heavy Weight Drill Pipe HWDP, or Drill Collar, but it is more likely to occur in the collar as it has a larger diameter than pipes and HWDP.

Causes Of Differential Pipe Sticking

To understand the causes of differential pipe sticking, you must understand what the stuck force is and the main factors affecting it. Differential pipe sticking force is the resultant force from the differential pressure between hydrostatic and pore pressure at a certain point. This Differential force will keep pushing the drill string or casing pipe toward the mud cake. Once you decrease that differential force, your drill string will be free. Below, we will explain the force calculation & the factors that affect it.

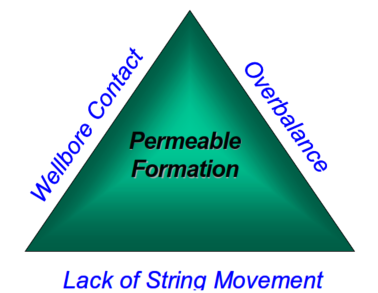

For differential sticking to occur, all four conditions must be present. However, it has been observed from studies of differential sticking cases that the most important factor in the triangle below is LACK OF STRING MOVEMENT. String movement is the only factor under the driller‘s control out of the four required conditions! When a string is left stationary, the filter cake builds up, and the string is embedded in the filter cake.

The Calculation Of Differential Sticking Force

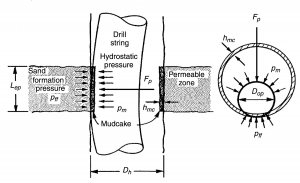

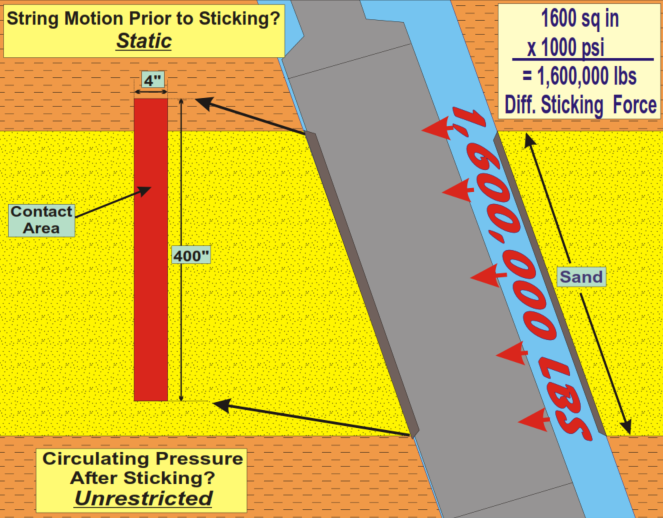

The actual differential sticking force that acts on the drill string is calculated from the well’s overbalance, contact area, and friction factor.

- The contact area estimates the contact length (calculated using the Wellplan for windows – Wellbore Contact module) multiplied by the contact width (usually assumed to be 2 to 3 inches).

- The friction factor (ff) will depend on the mud type used, but an average value of 0.25 is good enough for estimating differential sticking forces.

ΔP = Pm – Pff

Sticking Force Equation

We can calculate the pull force, Fp, which can free the stuck through this equation: Freeing Force = ff x contact length (inch) x contact width (inch) x overbalance (psi).

Fp = f ΔP Ac

Where:

- The differential pressure, Δp.

- The coefficient of friction, f.

- The contact area is Ac between the drilling mud cake and the differential sticking pipe surfaces. Ac can be calculated from this equation:

Ac=2 Lep {(Dh/2-hmc)2 – [Dh/2-hmc(Dh-hmc)/(Dh-Dop)]2}0.5

Dop ≤ (Dh-hmc)

Where:

- Lep is the length of the permeable interval.

- Dop is the stuck pipe outside diameter.

- Dh is the drilled hole diameter.

- hmc is the thickness of the filter cake.

- The dimensionless coefficient of friction, f, ranges from +/- 0.04 for oil-base mud to +/- 0.35 for water-base mud with no lubricants.

N.B: Upper calculation gives the force required at the stuck point to free the string and does not consider hole drag. The surface freeing force required would be the Freeing Force + Up drag + additional drag due to the overpulls (overpull margin) applied.

Example For The Force Calculations

Example: Calculation of force required to free a differentially stuck string: overbalance = 700 psi, contact length = 30ft = 360in, Contact width = 3in, friction factor = 0.25.

Solution:

FreeingForce = 0.25 x 360 x 3 x 700 = 189k lbs

Assuming 140klbs string weight above the stuck point, an up drag of 40klbs and calculating the extra drag due to the increase in tension due to overpull – say 30% of overpull lost in extra drag [typical for a horizontal well]

Surface force = 189k lbs*1.43 + 140kl bs + 40k lbs

Surface force =450k lbs

If you lose 30% of the surface overpull in extra drag, then:

0.7 x surface overpull = 189k lbs

surface overpull = 189klbs / 0.7 = 189k lbs * 1.43

From the above example, it can be seen that differential sticking freeing forces can easily reach very high values that are beyond the limits of grade ‘G’ and often grade ‘S’ drill pipe (API drill pipe Specs). Consequently, many of the mechanical methods for freeing differentially stuck drill strings are relatively unsuccessful. Prevention is the cure, as high freeing forces are required in differential sticking cases.

Factors Affecting The Sticking Force

The above Equations show the main factors that will cause the increase in the Sticking force and decrease the probability of the pipe-freeing process. These factors are:

- Unnecessarily high differential pressure between hydrostatic pressure and pore pressure.

- Thick filter cake (high fluid loss to the formation).

- Low lubricity filter cake (higher friction coefficient).

- Excessive differential Pipe Sticking length in the filter cake (time delay in freeing process).

- Hole and pipe diameters.

- Inclination plays a role in the pipe sticking force. They are uncontrolled variables once they are chosen for the well design objectives. However, collar shapes like spiral grooves, external-upset drill pipe tool joints, or squares can minimize the differential pipe sticking force.

Prevention And Mitigation

General precautions tips to decrease the possibility of Differential pipe sticking if drilling through high permeable intervals are as follows:

- Decrease drilling mud fluid loss. (Check API Fluid Loss, HPHT Fluid Loss).

- Decrease the amount of drilled solids in the drilling fluid Circulating system to obtain a thinner wall cake. Or, if it is OK, remove all drilled solids.

- Use the lowest possible mud weight to decrease hydrostatic pressure and further the stuck forces.

- Decrease Friction Coefficient by adding lubricants to the mud to give you a smooth mud filter cake.

- Decrease connection time and keep rotating the Drill String all the time.

- Consider the use of a drilling jar/bumper.

Design Team Prevention Points

- Use OBM rather than WBM. This reduces the risk of differential sticking by reducing the water loss to the formation and providing a thin, tough filter cake. This reduces the contact area as the filter cake will be thinner. (Freeing point – It also reduces the friction factor, allowing a greater force to be applied to the stuck point).

- Consider using low torque subs to provide stand-off for BHA’s and large sizes (6-5/8”) of HWDP.

- Use drilling jars and accelerators fitted with stand-off subs.

- A reduction in fluid loss will reduce sticking tendency.

- The liquid casing can reduce the risk of differentially stuck pipe for sealing off potentially lost circulation zones (i.e., high permeability).

- Agree on the directional surveying time with the survey engineer before taking the survey. Do not allow the survey engineer or directional driller to re-take the survey if the first one fails. Move the string for 10 minutes, then re-take the survey. A further risky time for differential sticking is when rotating with a low ROP, when the string may not move due to stick-slip conditions.

Rig Team Prevention Points

“KEEP THE STRING MOVING”

- Always know when the string is across a permeable formation.

- Make connections as quickly and safely as possible.

- Agree the surveying time with the survey engineer before taking the survey. Do not allow the survey engineer or directional driller to re-take the survey if the fi first one fails; move the string for 10 minutes, then re-take the survey.

- Agree on an action plan for when the string becomes differentially stuck.

- Develop a flow check procedure that reduces the risk of leaving the string stationary across a permeable formation.

- Have contingency plans

- If there is a Loss of power, go to the non-permeable zone

- Accidental power loss – maintain circulation if possible.

- Put mud weight back up after lowering it to get free unless specifi ed otherwise in the plan.

- Be aware that each formation is different.

Differential Sticking Pipe Warning Signs

Stuck pipe can occur when six factors are present simultaneously:

- A permeable formation.

- Lack of circulation between the drillstring and the filter cake.

- Thick filter cake, which is caused by high water loss.

- Insufficient drillstring movement.

- An overbalanced situation.

- Contact between the drillstring and the filter cake.

There will be signs or indicators while drilling permeable or depleted zones. If these indicators happen, you should think that you may get this kind of stuck:

- Torque And Drag increase.

- Unable to reciprocate or, at some times, rotate the String.

- Uninterrupted mud circulation.

- While drilling highly depleted zones, there may be a high-pressure variation, which may cause a stuck.

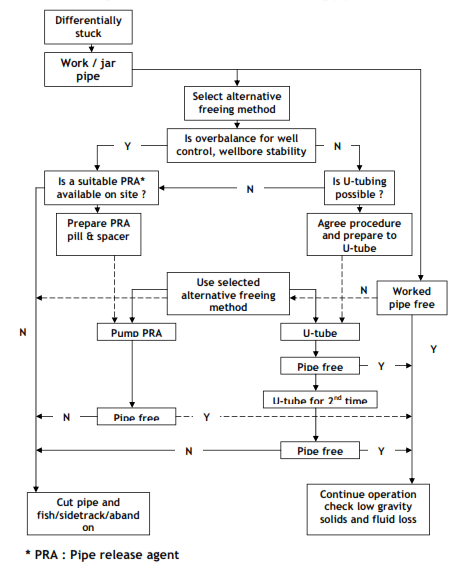

Differential Pipe Sticking Freeing Procedures & Tips

After you understand the freeing procedures, we recommend you look at the freeing chart.

First Action

- Start circulation at the maximum rate for +/- 10 mins (Kelly drive) or while applying torque (without tension for Top Drive)

- Work the pipe by applying cyclic slack-off and overpull combined with torque down to the stuck depth. (Top Drive)

- Always check the pipe yield stress reduction due to applying the torque.

- Reduce mud pump rate. +/- 1 BPM

- Start jarring down to release the Differential Pipe Sticking with the maximum jar-trip load. (Check Mechanical jar Operations & Hydraulic Jar Operations)

- Hold torque and set down weight until jar trips or for +/- 10 mins.

- Maintain slow circulation and jar down +/- 20 times.

- If the string doesn’t get free, release the torque, maintain slow circulation, and jar up +/- 10 times with max trip load.

- Suppose the string is still stuck; prepare a pipe-free pill while applying the continued jarring procedure.

- If the stuck point (also check free point calculation for stuck pipe) is near the bit, don’t apply torque; jar up with maximum jar load while preparing the pill.

Secondary Action

- Spot pipe-free pill at the drill string Differential Pipe Sticking point as soon as possible.

- Reduce the pressure differential to its bare minimum value, e.g., reduce the density of the drilling fluid or displace it entirely to a lighter fluid, even brine or oil-based mud, if available.

- Remove the wall cake by “dissolving” it by spotting pipe-lax pills dissolved in diesel oil or base oil. This can often take more than a day.

- You can also remove the formation by spotting acid over the stuck interval. This applies to acid-soluble formations only, i.e., limestones.

Care must be taken with this procedure because the chemical reaction between acid and formation produces gas, which will expand when it is circulated to the surface. This will reduce the hydrostatic column in the well and could, in critical cases, result in a kick

There are two important things that should be in your mind while freeing the differential pipe sticking problem:

- Minimize Hydrostatic Pressure

- Spot pipe-releasing agent

Minimize The Hydrostatic Pressure

Decreasing hydrostatic pressure is one of the things to think about for decreasing pipe sticking force and loosening Differential sticking in the string. But, of course, take into consideration the following:

- It should not affect the Well Control issue as it shall not be reduced below the maximum hydrostatic pressure on the well.

- It should not affect your mud in other meaning; don’t decrease your Oil Base Mud weight with water only, and this can be done by diluting your mud with the base fluid or by pumping lightweight pills.

- While reducing hydrostatic pressure, take care of any Kick Warning Signs.

Spotting Pipe Release Agents To Free Differential Stuck Pipe

Differentially Pipe Sticking can be solved by spotting a pill called a pipe-free pill as soon as sticking happens. These agents work on attacking and breaking down the mud filter cake to reduce the bonding between the mud cake and the Drill String.

It will be a good practice to pump a volume that covers the suspected Differential Sticking point with an excess of up to 100% and displace it so that it will be around the Differential stuck zone. You can reduce your pumping rate while it passes through the Differential stuck point.

Sometimes, you may leave the pill to soak while continuously working the torque and jarring down or jarring up without torque. The soaking time may be up to 12 hours, but you may have other problems from not circulating the well simultaneously, so you have another choice to circulate at a lower rate and prepare another pill.