Once the Casing Seating Depths and the Casing Size of each casing string are established, the weight, grade, and couplings used in each casing string can be determined via the casing design loads cases.

Loads Affecting Casing Strings

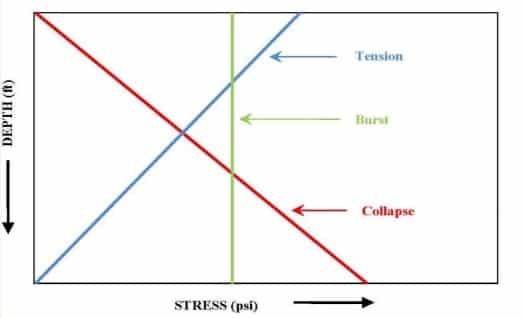

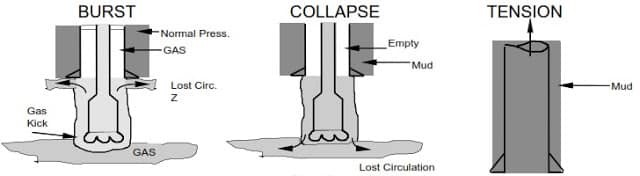

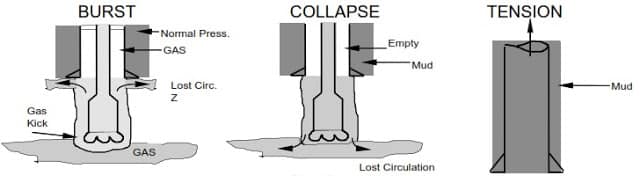

In general, each casing string is designed to withstand the most severe loading conditions anticipated during casing placement and the life of the well. The loading conditions that are always considered are Casing Burst, Casing Collapse, and Casing Tension.

When appropriate, other loading conditions such as bending or buckling must also be considered. Because the loading conditions in a well tend to vary with depth, it is often possible to obtain a less expensive casing design with several different weights, grades, and couplings in a single casing string.

It is often impossible to predict the various loading conditions that a casing string will be subjected to during the life of the drilled well. The assumed design load must be severe enough that there is a very low probability of a more severe situation actually occurring and causing casing failure. When appropriate, the effects of casing wear and corrosion should be included in the design criteria. These effects tend to reduce the casing thickness and greatly increase the stresses where they occur.

Criteria

In general, the minimum cost is achieved when casing with the minimum weight per foot in the minimum grade that will meet the casing design criteria is selected.

For this illustration, only API casing and couplings will be considered in the example applications. It will be assumed that:

- The cost per foot increases with the burst strength.

- The cost per connector increases with increasing joint strength.

General Casing design criteria will be presented for all Casing Types

Surface Casing Design Loads

Casing Design Loads Cases

Design loading conditions for surface casing are illustrated in below drawing for burst, collapse, and tension considerations.

The max internal pressure used for the Burst design is based on a Well Control condition assumed to occur while circulating out a large kick.

The max external pressure used for the Collapse design is based on a severe lost circulation problem.

The max axial Tension loading condition is based on assumption of stuck casing while the casing is run in the hole before cementing operations.

Casing Burst Design

The burst design should insure that formation fracture pressure at the casing shoe will be exceeded before the casing burst pressure is reached. Therefore, this design uses formation fracture as a safety pressure release mechanism to assure that casing rupture will not occur at the surface and endanger lives.

The design pressure at the casing seat = Fracture Pressure + Safety Margin.

So that to allow for an injection pressure that is slightly higher than the fracture pressure. If the fracture gradient is not known, a gradient of 1.0 psi/ ft may be safely assumed.

The Casing Surface Pressure = Bottom Hole Fracture Pressure + Safety Margin – Hydrostatic Pressure of the gas column.

- The pressure inside the casing is calculated assuming that all of the drilling fluid in the casing is lost to the fractured formation, leaving only formation gas in the casing.

- Assume a minimum gas gradient of 0.10 psi/ft for pressures originally shallower than 10,000 ft and 0.15 psi/ft for pressure sources deeper than 10,000 ft

- If the formations below the surface casing do not have any gas, then gradients of the formation fluids (oil or water) should be used

The External Pressure = Normal Formation Pore Pressure

- The external pressure, or back-up pressure outside the casing that helps resist burst, is assumed to be equal to the normal formation pore pressure.

- The beneficial effect of cement or higher density mud outside the casing is ignored because of the possibility of both a locally poor cement bond and mud degradation that occur over time.

- A safety factor of 1.1 is used to provide an additional safety margin during transportation and handling of the pipe.

The burst Load at the casing seat = Fracture Pressure + Safety Margin – Formation Pore Pressure

The burst Load at the surface = Surface Pressure inside the casing.

The Burst Casing Load Design Line

The burst load line is defined by two points; burst load at the casing seat and the burst load at the surface. Connecting the two points gives the burst load line in the casing from top to bottom. Multiplying the burst loads at the two points by a safety factor determines the burst design line.

Casing Collapse Design

The collapse design is based on the most severe lost-circulation problem that is felt to be possible or on the most severe collapse loading anticipated when the casing is run. Now lets consider the following:

- The maximum possible external pressure that tends to cause casing collapse results from the fluid that is in the hole when the casing is placed and cemented.

- The beneficial effect of the cement and of possible mud degradation is ignored

- The detrimental effect of axial tension on collapse-pressure rating is considered.

- The collapse rating should be de-rated above the neutral point using below equation.

- Below the neutral point the casing is in compression and adjustment of the collapse rating is not required. The depth of the neutral point of a casing string in mud can be calculated by the following formula:

Dn=Dt ( 1 – w/489 )

Dn = depth to neutral point, ft

Dt = setting depth of casing string, ft

W = mud weight, pcf

When correcting the collapse-pressure rating of the casing, it is recommended that the axial tension be computed as the hanging weight of the casing for the hydrostatic pressures present when the maximum collapse load is encountered plus any additional tension put in the pipe during and after landing.

The beneficial effect of pressure inside casing can also be taken into account by the consideration of a maximum possible depression of the mud level inside the casing. A safety factor generally is applied to the design-loading condition to provide an additional safety margin. The minimum fluid level in the casing while it is placed in the well depends on field practices.

The casing usually is filled with mud after each joint of casing is made up and run in the hole, and an internal casing pressure that is roughly equivalent to the external casing pressure is maintained. However, in some cases the casing is floated in or run in at least partially empty to reduce the maximum hook load before reaching bottom. If this practice is anticipated, the maximum depth of the mud level in the casing must be used in collapse calculations.

Casing Tension Design

Tension design requires a consideration of axial stress present when the casing is run, during cementing operations, when the casing is loaded in the slips, and during subsequent drilling and production operations.

The design load is usually based on conditions that occur when the casing is run such as casing stuck.

- It is assumed that the casing becomes stuck near the bottom of the hole and that a minimum amount of pull, in excess of the casing weight in mud, is required to pull the casing free.

- A minimum safety factor criterion is applied such that the design load will be dictated by the maximum load resulting from the use of either the safety factor or the overpull force whichever is greater.

- The minimum overpull force tends to control the design in the upper portion of the casing string, and the minimum safety factor tends to control the lower part of the casing string.

Summary

Once the casing design is completed, maximum axial stress anticipated during cementing, casing landing, and subsequent drilling operations should also be checked to ensure that the design load is never exceeded.

When the selection of casing weight and grade in a combination string is determined by collapse, a simultaneous design for collapse and tension is best. The greatest depth at which the next most economical casing can be used depends on its corrected collapse pressure rating, which in turn depends on the axial tension at that depth. Therefore, the corrected collapse-pressure rating cannot be computed until the axial tension is calculated. It takes an iterative procedure, in which the depth of the bottom of the next most economical casing section is first selected on the basis of uncorrected table value of collapse resistance, to be used. The axial tension at this point is then calculated, and the collapse resistance is then corrected. This allows the depth of the bottom of the next casing section to be updated for a second iteration. Several iterations may be required to arrive at a solution.

Intermediate Casing Design Loads

Intermediate casing is similar to surface casing in that its function is to permit the final depth objective of the well to be reached safely. When possible, the general procedure outlined for surface casing is also used for intermediate casing strings.

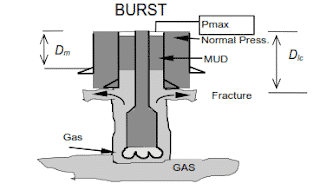

However, in some cases, the burst-design requirements in below figure are extremely expensive to meet, especially when the resulting high working pressure is in excess of the working pressure of the surface BOP stacks and choke manifolds for the available rigs. In this case, the operator may accept a slightly larger risk of loosing the well and select a less severe design load in which the burst limitation is equivalent to the BOP stack rating.

Casing Design Load

- The design load remains based on an underground blowout situation assumed to occur while a gas kick is circulated out. However, the acceptable mud loss from the casing is limited to the maximum amount that will cause the working pressure of the surface BOP stack and choke manifold to be reached.

- If the existing surface equipment is to be retained, it is pointless to design the casing to have a higher working pressure than the surface equipment.

- When the surface burst-pressure load is based on the working pressure of the surface equipment, Pmax, internal pressure at intermediate depths should be determined, as shown in in the below figure.

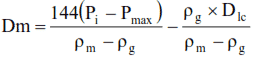

It is assumed that the upper portion of the casing is filled with mud and the lower portion of the casing is filled with gas. The depth of the mud/gas interface, Dm, is determined with the following relationship.

Where:

- Pi, in psi, is the injection pressure opposite the fractured zone:

The injection pressure is equal to the fracture pressure plus an assumed safety margin to account for a possible pressure drop within the hydraulic fracture. - ρm and ρg are the densities of the mud and gas in pcf :

The density of the drilling mud is determined to be the maximum density anticipated while drilling to the depth of the next full-length casing string. This permits the calculation of the maximum intermediate pressures between the surface and the casing seat - Dlc is the depth of the fractured zone in ft:

The depth of the fractured zone is determined from the fracture gradient vs. depth plot to be the depth of the weakest exposed formation

Intermediate Casing With a Liner

The burst casing design load criteria for intermediate casing on which a drilling casing liner (One of Types Of Casing) will be supported later must be based on the fracture gradient below the liner. The burst design considers the intermediate casing and liner as a unit. All other design criteria for the intermediate casing are identical to those previously presented.

Production Casing Design Load

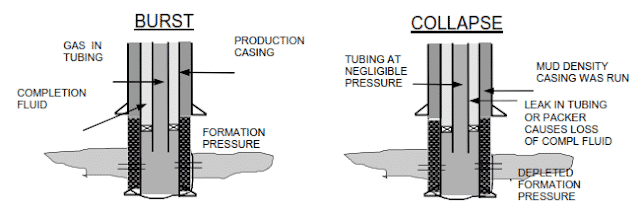

The Casing Burst Design Loads Assumption

- A producing well has an initial shut-inBHP equal to the formation pore pressure.

- A gaseous produced fluid in the well.

- The Production Casing must be designed so that it will not fail if the tubing fails.

- A tubing leak is assumed to be possible at any depth.

- It generally is also assumed that the density of the completion fluid in the casing above the packer is equal to the density of the mud left outside the casing.

- If a tubing leak occurs near the surface, the effect of the hydrostatic pressure of the completion fluid in the casing would negate the effect of the external mud pressure on the casing.

- Mud degradation outside the casing is neglected because the formation pore pressure of any exposed formation would nearly equal the mud hydrostatic pressure.

The Casing Collapse Design Loads Assumption

The collapse design load shown in below figure is based on conditions late in the life of the reservoir,

- When reservoir pressure has been depleted to a very low (negligible) abandonment pressure.

- A leak in the tubing or packer could cause the loss of the completion fluid, so the low internal pressure is not restricted to just the portion of the casing below the packer.

- Thus, for design purposes, the entire casing is considered empty.

- The fluid density outside the casing is assumed to be that of the mud in the well when the casing was run.

- The beneficial effect of the cement is ignored.

In the absence of any unusual conditions, the tension design load criteria for production casing are the same as for Surface Casing Design and Intermediate Casing Design. When unusual conditions are present, maximum stresses associated with these conditions must be checked to determine whether they exceed the design load in any portion of the string.

See Also

Example Which Shows The Steps And Guidelines Of The Casing Loads Design

Graphical Method, Casing Collapse And Burst Design

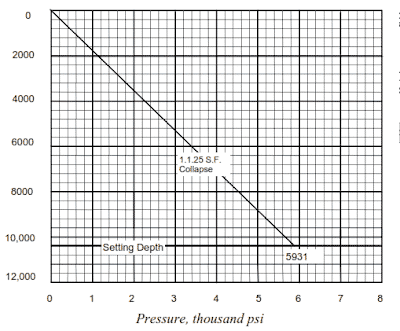

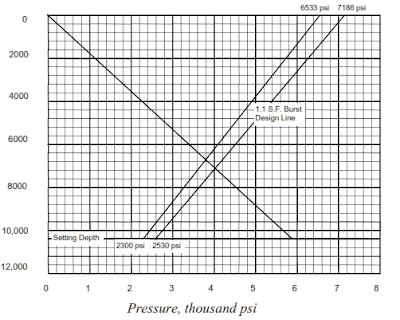

Since the Casing Collapse and Casing Burst loads vary linearly with depth, a plot may be made using the Example On The Previous Post.

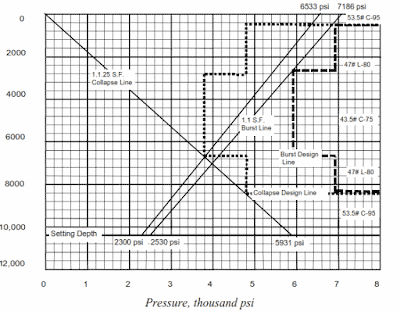

A casing collapse design line is drawn on a graph of depth versus pressure by using the hydrostatic pressure of 73 pcf mud at 10,400 ft. of 5,272 psi and zero hydrostatic pressure at the surface. The appropriate design factor of 1.125 is applied to the hydrostatic pressure and a line is then drawn (see below).

Similarly, the maximum burst load line is drawn on the same graph by connecting the burst load points of 2,300 psi at 10,400 ft and 6,533 psi at the surface. The burst design line is established by multiplying 2,300 and 6,533 psi by the burst design factorof 1.1 or 2,530 psi at 10,400 ft and 7,186 psi at the surface and drawing a line between these two points.

The first section of pipe is selected based on the casing collapse requirement at the settingdepth. In this example 53.5# C-95 has a casing collapse rating of 8960 psi which is off the chart. The casing collapse rating of the next weaker section is plotted on the appropriate collapse design line and the changeover depth read at the intersection on the graph. A vertical line for the first section is drawn from the casing setting depth to the changeover depth and a horizontal line is drawn from the intersection of the second casing collapse rating plotted on the design line to the collapse rating of the first section. Subsequent segments are similarly determined. Concurrently burst ratings are plotted and vertical and horizontal lines are drawn.

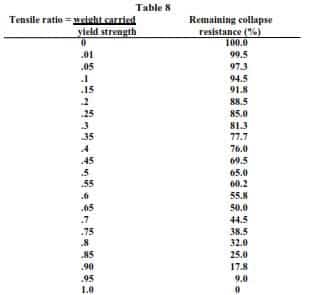

Above the cement top and when the casing is in tension, the casing collapse ratings are reduced by the effect of tension on collapse.

At changeover depths above the cement top, the axial stress is calculated. Where the pipe is in tension, a percent of rated collapse is read from Table below based on the Axial Tension. Using the percent of rated collapse multiplied by the changeover depth adjusts the depth to the correct depth. The casing collapse design factor at the bottom of the weaker section then is calculated to determine if the casing collapse design requirements are sufficient. If the depth is not correct, the design factor calculated times the depth used will adjust the changeover point to the correct depth. By repetition the correct depth will finally be selected. If the pipe is not in tension, plot the collapse rating of the next weaker section in collapse on the design line and continue the design as before.

Asthe design continuesupward from the bottom a depth will be encountered where casing collapse no longer controls the design. Above this depth the design will be controlled by burst or tension.If burst controlsthe design, the burst ratings of the casing are plotted on the burst design line and the burst loads are read from the burst load line at the corresponding depth. Changeover depths are read directly from the graph. If tensionis controlling the design, the changeoverdepth is calculated directly. The changeover depth iscalculated by using the tension rating divided by 1.6 and subtracting the buoyed weight ofthe pipe below; from this remainder divide by the buoyed weight per foot of the pipe used to determine the footage of pipe to be used.