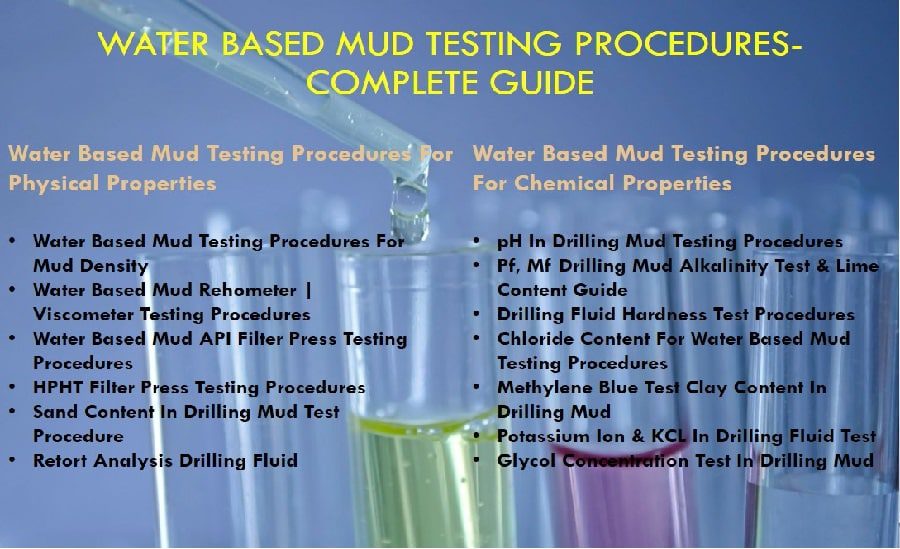

The following water-based mud testing procedures follow approved ANSI/ API RP 13B-1. In this article, we will provide all the procedures for all the mud tests related to WBM, including physical properties and chemical properties. But first, before going in-depth on our subject, let’s have a look at Safety Precautions While Mud Testing.

Water Based Mud Testing Procedures For Physical Properties

These test procedures are for both Water-based mud and oil-based mud so we will add it here and in the article of oil-based mud testing procedures.

- Water Based Mud Testing Procedures For Mud Density

- Rehometer | Viscometer Testing Procedures

- Water Based Mud API Filter Press Testing Procedures

- HPHT Filter Press Testing Procedures

- Sand Content In Drilling Mud Test Procedure

- Retort Analysis Drilling Fluid

Water Based Mud Testing Procedures For Chemical Properties

pH In Drilling Mud Testing Procedures

pH in drilling fluid is one of the major drilling fluid properties for monitoring as it affects clay interactions, corrosion processes and solubility of certain chemicals. We can determine drilling fluid pH using a pH Meter or pH Strips, as follows. Accordingly, we will explain the steps of PH in drilling fluid testing procedures.

Pf, Mf Drilling Mud Alkalinity Test & Lime Content Guide

The alkalinity test is one of the important Water Based Mud testing procedures. It affects the performance of some treating additives in water-based fluids, especially if they require alkaline conditions for better performance. Sodium or Potassium Hydroxide normally provides the hydroxyl ions (OH–) for calibrating the pH of water-based fluids. However, carbonate (CO3 2–) and bicarbonate (HCO3 –) ions also increase fluid alkalinity, along with the formation of contaminants (e.g., H2 S or CO2 gas).

Drilling Fluid Hardness Test Procedures

We can define Water “hardness” as water that contains dissolved Calcium and Magnesium salts, which in high concentrations will decrease the performance of Bentonite and polymers ( check also How to Design Polymer Mud), resulting in consuming large amounts. In this article, you shall learn the water-based mud testing procedures for Total Hardness as Calcium & Calcium and Magnesium Ion Content.

Chloride Content For Water Based Mud Testing Procedures

The water-based fluid may have chlorides from the base fluid (e.g. Sodium or Potassium Chloride), or may pick up chlorides while drilling. The application of the Chloride Test is determining any changes in water-based mud salinity. An increase or reduction in salinity will indicate salt or water contamination. So It is important to have chlorides in drilling mud.

Methylene Blue Test Clay Content In Drilling Mud

We use this Clay Content test in drilling mud to estimate the Cation Exchange Capacity (CEC), which estimates the reactive clays in the drilling fluid system. This article handles the Methylene Blue Test For clay content in both drilling fluid and shale samples.

Potassium Ion & KCL In Drilling Fluid Test

Monitoring potassium ion concentration for water-based fluid systems that utilize potassium as a shale inhibition agent is essential. It will deplete once it is adsorbed into shales. Monitoring Depletion and Maintaining effective inhibition levels are essential in the drilling fluid system. So you can easily estimate Potassium ion concentration by adding excess Sodium Perchlorate to a certain volume of mud filtrate to precipitate out Potassium Perchlorate. In this article, you shall learn how to measure, calibrate & calculate Potassium Ion & KCL In Drilling Fluid.

Glycol Concentration Test In Drilling Mud

Mud engineers generally utilize Glycol in KCl-Polymer fluid systems as it improves Shale Inhibition. In addition to that, Glycol will be lost through adsorption on exposed shale formations in the wellbore and on the cuttings. Also, it is important to understand that the glycol depletion rate is a function of drilling Penetration Rate (ROP) and Cuttings size. Based on the above, Mud engineers always monitor the glycol concentration in drilling fluid. In this article, you will be able to understand the equipment and the steps for such a test.

THANK YOU FOR YOUR SUPPORT