Samples are examined under a microscope for:

- lithology

- oil staining

- porosity.

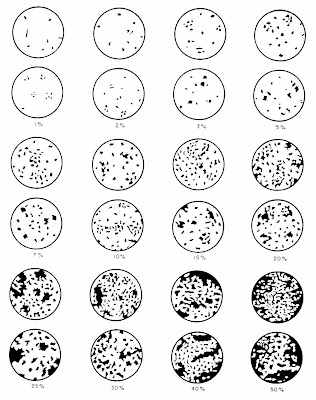

The objective is to depict changes in lithology and the appearance of new formations. The microscope and ultraviolet light are complementary tools in reconstructing the characteristics of the originating strata. An estimate of the lithology, staining, and porosity percentages is made carefully since factors such as grain shape and size, color, distribution, etc. can affect the relative percentages Figure.1.

Sources Of Drilling Cuttings Contamination

There are many potential sources of contamination when undertaking estimates of lithology percentages. Some examples are:

1) Cavings

(cuttings from previously drilled intervals rather than fr

om the bottom of the hole) Although the cuttings are first washed through a coarse sieve to remove cavings, some may remain in the sample.

Cavings can generally be recognized as large, splintery rock fragments that are often concave or convex in cross-section. They are lithologically identical with formations from higher sections in the open hole. If found in large quantities, it may indicate a severe underbalanced drilling mud condition or a situation where pipe rotation is too fast, and Stabilizers are catching on the side of the hole.

2) Recycled cuttings

If cuttings are not efficiently removed from the drilling fluid at the shale shakers, desanders, and desilters, they may be recycled through the mud system. Recycled cuttings are recognized as being small, abraded, rounded rock fragments in the sample. Microfossils, which have been recycled, can lead to serious correlation problems.

3) Mud chemicals

Some mud chemicals can be confused with rock types. Lignosulphonate, for example, resembles lignite, and bentonite can be erroneously identified as montmorillonite clay in a poorly mixed mud system. Moreover, lost circulation material (LCM), such as nut shells, fibers, and mica flakes, are common sources of contamination when drilling lost circulation zones.

4) Cement

Cement contamination is usually encountered when drilling after casing or while sidetracking well. Cement can be mistaken for siltstone but is readily identified by testing with a phenolphthalein solution. Man-made cement stains purple due to its high pH.

5) Metal

Metal is occasionally found in samples and frequently originates from wearing the inside of the Casing by the Drill String. This is often remedied by using rubber Drill Pipe protectors. Other sources of metal fragments are bits, lost sidewall bullets, and the products of milling operations (check also: Milling In Drilling Operations). Large amounts of metal should be reported to the tool pusher.

Causes Of Unrepresentative Cutting Samples & Good Logging Practices

In some cases, samples may be unrepresentative of the drilled formation. For example, in evaporite sections drilled with a Water Based Mud, salts will dissolve and there will be no lithological indication of their presence in the lagged samples. However, evaporites can still be recognized using good logging practices:

- Evaporites generally have consistent drill rates

- Gas values through evaporites will be very low

- There will be poor or no returns at the shale shakers

- Limestones and dolomites are frequently found in association with evaporite deposits

- Anhydrite sections can usually be identified by BaCl solution, which produces BaSO4 precipitate.

- The chloride content of the drilling fluid will increase significantly

Other causes of unrepresentative samples are:

Cuttings may be absent when drilling soft clays/shales. These will tend to disperse/dissolve in the drilling fluid making a “native mud”. This can be recognized by the change in the drilling fluid’s properties, most commonly viscosity and mud density.

High rotary speed drilling (turbines and PDM‘s) often produces very fine “rock flour”. The same happens when drilling with diamond bits.

When drilling with diamond bits, the heat generated at the bottom of the hole can “burn” the cuttings to such a degree that they will appear like metamorphosed rocks.