ACP / ECP annular casing packers (also known as external casing packer) are one of the packers types that is popular because they provide improved sealing and centralization (check also: Permanent Packers). They are used to:

- Prevent gas migration.

- Reduce the gas-to-oil production ratio.

- Reduce or prevent water production.

- Isolate production or injection zones.

- Avoid squeeze cementing.

External Annular Casing Packer ECP / ACP Applications

- Landing Nipple In Well Completion

- Well Control On Rigs: 15 – Checks & Tests

- Snubbing Units In Oil & Gas Field

- Casing Running Procedures Good Practice

- Drill String Design Calculation Steps

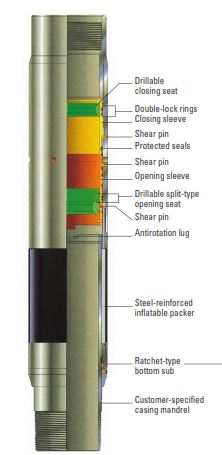

ACPs vary in size and valve type depending on their purpose. Most can be filled with mud or cement, but the amount of pressure they can withstand is limited. Overfilling is a major cause of casing packer failures. Two types of ACPs are shown in Fig. 1.

Annular packoff equipment (packer shoes, collars, and ACPs) is used to protect areas of the formation from excessive hydrostatic pressure, contaminating fluids, or both. The equipment has expanding rubber elements that pack off against the formation to create an impermeable annular barrier. The rubber elements also centralize the casing when expanded.

External casing packer is generally used below-stage collars or port collars to protect the formation below from excessive hydrostatic pressure or contamination (Fig. 2 & 3). They are also used in an attempt to block gas and fluid migration. ACPs can be installed on either side of a weak formation.

Running in Hole

Shows packer stage collar in running position with opening and closing sleeves pinned in place. The lower section of the split-type opening seat isolates inflate passage, preventing premature inflation of the packer.

Inflating Element

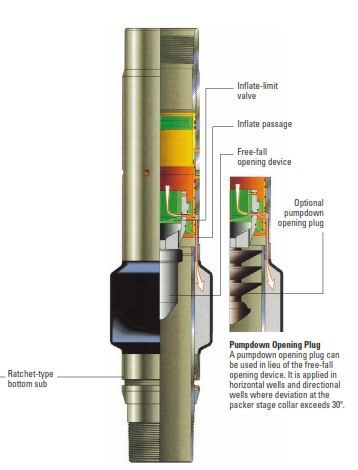

The free-fall opening device enters split-type opening seat, shearing the pins in the lower section. This allows lower section to move down exposing the inflatable packer element to the fluid and pressure inside the casing. Fluid enters the packer element through the double-seal in the free-fall opening device and the split-type opening seat and inflation passage in the tool body.

External Casing Packer ECP Mechanism

ACP / ECP Packer can be packed off by either inflating or compressing the rubber element (Fig. 4). The inflatable type is generally larger and more capable of packing off oversized or irregular holes. The inflation process generally begins at a predetermined setting pressure. The setting pressure should be sufficiently high to prevent premature packoff while mud conditioning or Primary cementing.

An optional break-off rod may be used to prevent premature setting by blocking the inflation port until broken free by a wiper cementing plug. Once the element is inflated, an internal valve mechanism will hold the inflated position, and the surface pressure may be released. When possible, the element should be inflated with cement.

Packer Shoes

Packer Shoes and collars are considered one of the external casing packers that have other applications:

- Packing off the open hole below the casing to assist in protecting low-pressure formations against cement contamination

- Floating and guiding casing to bottom

- Allowing fluids to be circulated through the casing before the tool is set in the open hole

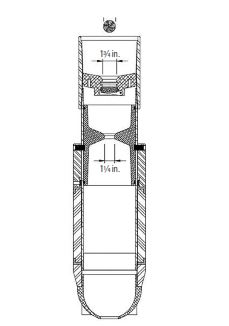

Annular casing packer shoes are hydraulically set by a tripping ball (Fig. 4). With the casing in place, the tripping ball is dropped and allowed to fall to a seat on the piston. As pressure is applied, the load is transferred to an external sleeve that compresses and expands the element. At a pressure of approximately 800 psi [5.5 MPa], the piston shears free, uncovering the ports. The external sleeve contains a ratchet mechanism that permanently holds the set position. The cement is pumped and, unlike stage equipment, the ports are not closed.

Basket Shoes

Basket shoes use a basket instead of an expanding rubber element to pack off the annulus. They provide the same function as a packoff shoe but are limited to low differential pressure applications and do not create a true hydraulic seal.

References:

- Well Cementing Second Edition – Erik B. Nelson and Dominique Guillot