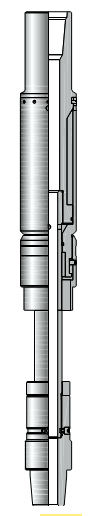

The principal advantage of hydraulic set liner assemblies is that no rotation of the liner assembly is necessary to set the slips. The activation of the setting mechanism in a hydraulic-set liner hanger assembly is by creating a sufficient differential pressure to initiate the setting sequence. Normally, differential pressure is created by applying pressure down the drill string from the surface.

Because one threaded connection is necessary between the body and the lower sub (Drilling Subs) containing the hydraulic setting mechanism, this type of design provides increased pressure integrity.

Hydraulic liner assemblies can be manufactured with a single cone or with tandem cones, depending on the required hanging capacity and the bypass area of the liner assembly when the slips are in the set position.

Main Applications Of Hydraulic Liner Assemblies

- Firstly, where rotation of the liner assembly is not available due to doglegs, poor overall hole geometry, etc.

- Secondly, when installing one-liner inside of a previously set liner.

- Thirdly, where differential pipe sticking is a concern. And, the casing below the Casing Liner (read also the Types Of Casing) may not be able to rotate successfully.

- Fourthly, in installations on floating offshore drilling rigs where reciprocation of the liner is not an option. (Due to the motion of the rig.)

Mechanical or hydraulic setting mechanisms are typically adapted to perform a variety of specialized Liner installation, setting & cementing operations including:. (Primary cementing & Stage Cementing)

- Reciprocation of the liner during cementing operations.

- Rotation of the liner during cementing operations.

- Reciprocation and rotation of the liner during cementing operations.

- Manipulation of the liner without disengagement of the running tool to aid in the placement of the liner.

- Rotation of the liner during cementing operations after the setting tool has been disengaged.

Major Types Of Hydraulic Set Liner Hanger

There are two types of hydraulically activated setting mechanisms: internal and external.

Internal Hydraulic setting Mechanisms

The Internal hydraulic setting mechanisms are are incorporated as an integral part of the hanger design and remain in the well. The setting sequence was initiated hydraulically. Slips set mechanically by lowering the drill pipe ( Check API Drill Pipe Specs).

Generally, the setting sequence of a liner assembly with an internal hydraulic setting mechanism that initiates the setting sequence and sets the slips mechanically is:

- Position the liner at the desired setting depth.

- Release a setting ball from the surface and circulate until the ball seats in the landing collar.

- When the setting ball seats, pressure up sufficiently to shear the pins in the setting piston of the liner hanger. ( Check Schl Ball Seat). Then, move the slips upward onto the cone.

- Lower the drill string while maintaining the pressure until the cone forces the slips outward to engage the wall of the supporting casing. (Check Drill String Design Guide)

- Continue to lower the drill string until the liner hanger supports the full liner weight.

External Hydraulic Setting Liner Hanger Mechanism

The external hydraulic setting mechanisms incorporated into the liner setting tool. And, removed from the well at the completion of the installation. When activated, they initiate the setting sequence, creating sufficient force to engage (penetrate) the slips in the supporting casing. Compression or tension forces are not required for slip engagement in the supporting casing.

Because of the magnitude of the force they create, external hydraulic setting mechanisms are ideal for setting liner hangers and energizing packing elements in high-angle or horizontal environments.

Generally, the setting sequence for an external hydraulic setting system which initiates the setting mechanism and sets the slips hydraulically is:

- Position the liner at the desired setting depth.

- Release a setting ball from the surface and circulate the ball to the liner setting tool.

- Pressure up sufficiently to shear the screws in the setting sleeve of the setting tool allowing the setting tool sleeve to move downward until the packer slips into contact with the cone and are forced outward to engage the supporting casing wall.

- Hold the applied pressure for 3-5 minutes.

- Bleed off the applied pressure and alternate applying compression and pulling tension to insure the slips are properly set and the full weight of the liner is supported.

- Release the setting tool from the hanger and pull the setting tool from the well.

Ref: Weatherford Liner Hanger Applications