The variety of methods & procedures available for providing the setting mechanism for the seal elements of a packer leads to a significant number of options for installing and completing a well. Consider firstly therefore the setting methods for wells packers.

Each of the possible methods for setting a packer is outlined below:

Packer Setting Mechanisms & Procedures

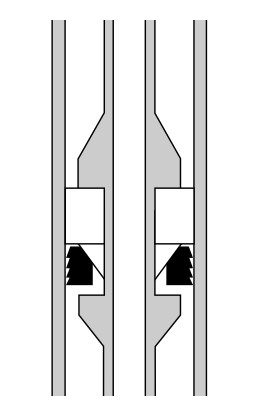

Weight-Set or Compression Set Packers

This type of packer – figure 1- can either be set independently or can be run in as an integral part of a tubing string and set when the string is landed off.

Normally weight set packers utilize a slip and cone assembly which can be actuated to supply the compression of the seal element, once the drag springs or friction blocks can engage the inside wall of the casing. The means to release the slips are usually obtained using a J slot device which upon activation allows string weight to be slackened off and thus compress the sealing element. Release of the element can be obtained by picking up string weight.

This type of packer setting procedure will only be suitable if weight can be applied at the packer which may not be the case in highly inclined wells. In addition, the packer will unseat if a high-pressure differential exists from below the packer.

Compression-set packers generally require 8,000 to 14,000 pound minimum setting forces on the elements (packer element durometer and temperature at setting depth must also be considered). This can, of course, be a problem at less than 2,000 feet since the necessary drill pipe weight is questionable depending on the packer size and tubing size/weight per foot.

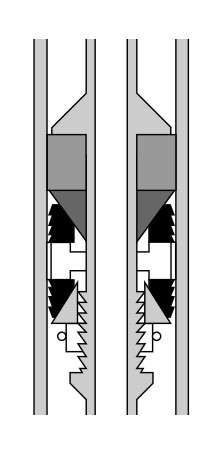

Tension Setting Packers p

This type of packer is effectively a weight set packer run upside down, i.e. the slip and cone system is located above the sealing element. They are particularly useful for applications where a high bottom hole pressure and thus a differential pressure from below the packer exists. This situation occurs in water injection wells, where the injection pressure will assist in maintaining the packer setting. Care should be taken to ensure that any temperature increase in the string and consequent string expansion will not provide a force capable of unseating the packer.

The most common choice for a shallow set completion is the mechanical- tension-set packer. This is probably because a shallow well generally indicates more marginally economic circumstances and the tension-set mechanical tend to be less expensive than the hydraulic set or wireline set retrievable counterparts.

Roto-Mechanical Set Packers

In this type of packer, the packer setting procedure is actuated by tubing rotation. The rotation of the string either

- forces the cones to slide behind the slip and thus compress the seal, or

- releases the inner mandrel such that tubing weight can then act upon the cones to compress the sealing element.

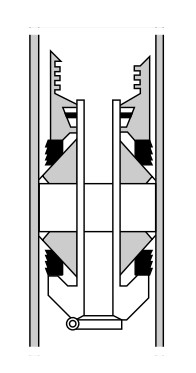

Hydraulic-Set Packers

In this type of packer, the procedure of the setting depends on hydraulic pressure generated within the string that is used to either:

- drive a piston to effect the movement of the slip and cone system thus comprising the seal element, or alternatively

- actuate a set of upper slips in the packer which will then fix the packer position and allow tension to be pulled on the packer and compress the seal system.

In the former arrangement, once the hydraulically driven piston has actuated movement of the cone, return movement of the cone must be prevented by a mechanical lock device.

To allow the hydraulic pressure to be generated in the tubing prior to the setting of the packer, 3 main procedures are available for plugging the tubing:

- The installation of a blanking plug such as a Baker BFC plug inside an appropriate nipple such as the Baker BFC seating nipple.

- The use of an expendable seat into which a ball can be dropped down the tubing string. Upon applying overpressure after setting the packer, the ball and seat shear out and drops into the well sump. An alternative design features an expandable collet that will move down and expand into a recess once overpressure shears the pins, thus allowing the ball to pass through.

- The use of a differential displacing sub, allows the tubing fluid to be displaced through ports on the sub prior to setting the packer. The ball when dropped will seat on an expandable collet which will allow pressure to be generated. Once overpressure is applied the collet moves downwards and in so doing, closes the circulation valve and allows the ball to drop through.

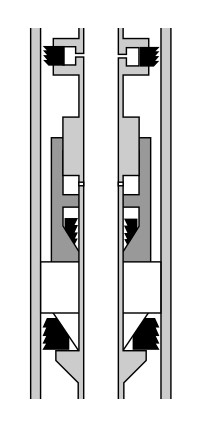

Electric Wireline Setting Packers

In this system, a special adaptor kit is connected to the packer, with or without the tailpipe, and the system is run into the well on the wireline with a depth correlation instrument such as the casing collar locator C.C.L. At the setting depth, an electrical signal transmitted down the cable ignites a slow-burning explosive charge located in the setting tool which gradually builds up gas pressure and actuates a movement of a piston to compress the seal system.

This type of system leads to a more accurate setting depth definition for a packer plus a fairly fast setting/installation procedure. The disadvantages are the difficulty of running wireline in high-angle wells and the fact that the packer must be set separately from the subsequent installation of the tubing.

15 Tips For Packers Running, Setting Procedure, and Space-out Considerations.

- Very deep set capability. Situations requiring production packers to be set very deep (12,000 feet/3,658m +) indicate the need for setting mechanisms that are not dependent on tubing manipulation, namely the hydraulic and electric line set packers. This is due to the increased possibility of tubing manipulation (especially rotation) problems with increased depth. Hydraulic and electric wireline setting systems are free from this potential limitation. The most popular packer selection for deep set applications are the E/L set or hydraulic set permanent packers. The preference of permanent over retrievable is probably due to other conditions usually accompanying deep wells. These conditions (increased temperature and pressure differential requirements) are more easily and most often satisfied by permanent packer design features.

- Packer setting procedure without pump or electric line unit-(mechanical set). At times it is necessary to utilize a specific packer setting mechanism because the associated support equipment is not available to accomplish the setting operation by some other means. For example, if a mud pump is not available for hydraulic setting and an electric line unit is not available for wireline setting then a mechanical set packer is the remaining choice.

- Setting on the pipe without tubing manipulation-(hydraulic set). If electric line set capability is not available for some reason and hole conditions or pipe handling equipment makes tubing manipulation difficult or impossible, hydraulic setting is the remaining choice. The most popular choices in this situation are standard hydraulic set retrievable packers or permanent packers. However, given other considerations including availability, another possible choice is the use of an electric line set packer (permanent or retrievable) run-on tubing with a hydraulic setting tool. This piece of accessory equipment is removed from the well with the tubing after it is used to set the packer.

- Run and set the packer quickly and accurately-(wireline set). It is sometimes desirable or necessary to be able to run and set a packer as quickly and accurately as possible. In these cases, the need is often related to another need – the need to plug the well. The electric line set packers, whether permanent or retrievable, are considered most appropriate. Many accessories area available for use with these packers to accomplish this related need for plugging. The setting depth accuracy is accomplished by correlating depth using an electric line collar locator which is run above the setting tool.

- Heavy tailpipe carried on bottom of packer-(solid connections through packer). In order for a packer to be able to carry in long lengths of pipe below it, it is necessary that the packer have a solid mandrel through to the lower tubing thread or if not, the release mechanism must allow for a strong enough bearing mechanism in the run position to carry the weight. Some packers may need accessory equipment or modifications to insure retrievability after set. Others may be limited in the amount of weight that may be run in by the setting pins. This is true of some hydraulic packers. Also, in the case of electric line packers, if the pipe weight exceeds the recommended tensile rating of the line itself, it would be necessary to use the accessory hydraulic setting tool.

- The packer hydraulic setting procedure with low set pressure-(large setting piston area). At times it is necessary to be able to hydraulically set a packer using lower pump pressure because of surface or downhole support equipment or completion equipment pressure limitations. Assuming that the majority of element packages set with about the same force and pressure capability is limited, then the only other variable is piston area. Some hydraulic packers are designed with a large piston area. The piston areas will, of course, be dependent on the dimensional and pressure limitations of the design. At times, a double piston can be utilized to lower the necessary pressure needed for the desired setting force.

- Multiple set/release on same trip-(mechanical-set retrievable). Many times well conditions and operational goals make it necessary to run a packer that can be set and released multiple times. Several different packer design features are necessary for this capability. However, the possible combinations are complex and need not be detailed at this point. These packers generally referred to as “hook wall packers”, are specifically designed for these needs.

- Retrievable bridge plug capability, bi-directional pressure, tubing and packer retrievable. The capability to use a production packer as a retrievable bridge plug is desirable in many different completion situations. Basically, this capability simply means the packer can be left in the hole in a plugged condition (tubing is retrieved separately). To further fit the definition, the packer must have bi-directional pressure holding capability and the packer itself must be retrievable.

- Because production packers are designed to be produced through, the necessary plugging ability is not naturally a part of any production packer and must be added on as accessory equipment. Overshot tubing seal dividers, flapper valves, foot valves, tubing nipples with wireline plugs and retrievable sealing plugs are all examples of such accessory equipment. The most effective matching of packer types and accessory plugging equipment types is dependent on the design of each.

- Permanent bridge plug capability, bidirectional pressure, permanent packer. The same basic criteria apply to permanent bridge plug capability as with retrievable but without the packer retrievability requirement. Also, the accessory plugging equipment is essentially the same.

- Run and set in deviated/crooked hole, run on tubing, hydraulic set capability. Offshore platform drilling and other difficult drilling conditions today have produced a greater number of wells that are highly deviated or even horizontal. Because of the particular difficulty of downhole tubing manipulation, especially rotation, mechanical set packers are not generally desirable. Those requiring multiple rounds at depth instead of 1/3 turn would be most likely to pose setting problems. Packers requiring rotation for release would be even more likely to result in operational difficulties.

- Electric line set capability can also be a problem under these well conditions because no pipe weight is available to overcome the friction between the packer assembly and the casing in a deviated hole, and the chances of getting the packer to depth are reduced. In a horizontal completion, this would be out of the question.

- Hydraulic set packers or packers run on the hydraulic setting procedures are most likely to be successful since they require no tubing manipulation and can take advantage of pipe weight.

- Easy sting-in of seals in the deviated hole-(scoop head). Also associated with deviated holes is the possible problem of stinging seal units into the packer. Packers with special “scoop heads” or tube guides are the best designs for reducing the chance of this problem. Another thing to consider is the packer ID. The larger the ID (and OD of the seals), the greater the chance for sting-in success. A “Muleshoe” guide is generally used on the seal assembly to increase the chances of stinging into the packer. The size of the Muleshoe guide is naturally dependent on the seal OD. The larger the seal OD, the larger the Muleshoe guide. This should result in easier stringing. There are also Muleshoe guides on the market that reciprocate with the up and down motion of the tubing.

- Run and set in heavy drilling mud type, run on the tubing. Sometimes well conditions make it necessary to run and set the packer in heavy mud. Electric line set packers are many times undesirable because running time in the highly viscous mud may be very long or it may become impossible to get the assembly to depth if the mud is in poor condition. The assembly weight itself may not be sufficient.

- As in deviated or crooked wells, packers run on tubing have the advantage of the pipe weight. Also, mechanical set (especially multiple rotation set) packers may pose a problem. Poor mud conditions can result in difficulty getting the necessary movement between the moving parts to get the packer set.

- Even the remaining alternative, the hydraulic setting is not without possible problems. The necessity of dropping the setting ball or running a wireline plug-in heavy mud may become a problem and be time-consuming if the mud is in poor condition. The chance of the mud conditions deteriorating is high because, during the time-consuming running operations, circulation to the bottom is not possible.

- Leave tubing in tension, upper slips, or internal latch. Operational conditions requiring that the tubing be spaced-out in tension are numerous. Production conditions such as a high-flowing bottom holes and surface temperatures would be an example. The use of side pocket gas lift mandrels and the associated frequent wireline service work would make it desirable to keep the tubing in tension for optimum serviceability.

- If a packer is to be used and the tubing placed in tension, the packer must have a set of upper slips. If the packer has an integral bypass, it must also have an internal latch of some kind so that the bypass stays closed when the tubing is placed in tension. Permanent or seal bore type retrievable packers may be used for this purpose as long as there is an associated latching type locator run with the seal assembly. The exception to these requirements is if a lower packer with latch and the upper hold-down mechanism is used to set the element package of an upper packer with no upper slips. These are most often used in zone isolation applications.

- Leave tubing in compression, lower slips, or lower stop. The need to leave the tubing spaced out in compression is usually related to possible subsequent treatment operations. The compression is often left to overcome the tubing shrinkage usually associated with treating. A set of lower slips is necessary to allow for this space-out option. The only exception is if a lower packer is used as a stop for an upper packer without lower slips. These exceptions are most often found in zone isolation applications.

- Leave tubing in neutral (Neutral point in drilling), lock compression in element package. The need to leave the tubing in neutral can be generated by a large variety of operational conditions or goals. In general, a tubing in neutral space-out affords some accommodation for tubing elongation during production as well as tubing contraction due to treatment operations. If neither operation results in extreme movement, then this neutral space-out condition may be optimum. For a packer to be capable of being run and set and then the tubing left in neutral, the packer should have bi-directional pressure capability and must be of such a design that the element compression is maintained by some means other than the tubing compression or tension. This is “automatic” for permanent and seal bore type retrievable packers but for retrievable packers, it means an internal latch mechanism is necessary.