Roller reamers are a unique tool used in drilling through tough rock formations. They’re designed to stabilize the drilling process and create a smooth, round hole. Rolling reamers have a very small contact area with the rock unlike other reaming tools. But don’t let their small size fool you. They’re actually the most effective tool for reaming hard rock. In fact, when drilling and encountering problems with the rock bit gauge, it’s always a good idea to use a rolling cutter reamer. They’re the lowest contact tool available and can help you do the job safely and efficiently.

Generally, we can say that significant reamer types are under-reamers, roller reamers, RFID, near-bit, and expandable reamers. This article is a part of the series explaining Drilling Bottom Hole Assembly Components, Types, and Mechanisms.

Drilling Reamers Application In Oil & Gas

As it is required to drill more deep boreholes and deepwater wells, their costs, time, and risks related to tripping pipe for long drill string became significant elements of the drilling design. In some deep wells, tripping pipe time exceeds the drilling bit life. There are four reasons for Drill String tripping: drilling bit change out, wiper trips, directional re-orientation, and casing running.

There are a few options for a casing run and worn Drilling Bit. Also, Most directional re-orientation can be done from the surface. So the reaming trip will be the main reason for performing a trip. Reaming while drilling or wellbore enlargement is the primary process in drilling swelling formations, salt structures, and deviated wells, either for a casing run or to keep a hole in the gauge. The task of hole enlargement can be done in five ways, which rely on the required hole enlargement radius, formation makeup, and enlarged section depth:

- Separate reaming trip.

- Simultaneous reaming while drilling.

- The use of Drilling String roller reamers (limited radius and constrained by casing ID).

- The use of an overlarge Drilling Bit (limited by casing ID and used only for top-hole).

- Increase nozzle velocity to enlarge the hole hydraulically while drilling (limited to medium and soft formations).

In conclusion, there are cost advantages to reaming while drilling. The pilot hole offers reasonable directional control while the enlarged hole from reaming creates the right conditions for running casing or completion equipment which relates to savings in time and cost.

Drilling Reamers Types

Under-reamers

A drilling under reamers type is a device designed to run in conjunction with a Drilling Bit. It has cutters that can be expanded or contracted by hydraulic or mechanical means and can ream or enlarge boreholes below the casing. It can be used in hydrocarbon, geothermal, or water wells.

Drilling under reamers can be positioned either above the Drilling Bit or a pilot assembly run inside the existing borehole. Numerous designs exist, in sizes varying from a couple of inches to 40″.

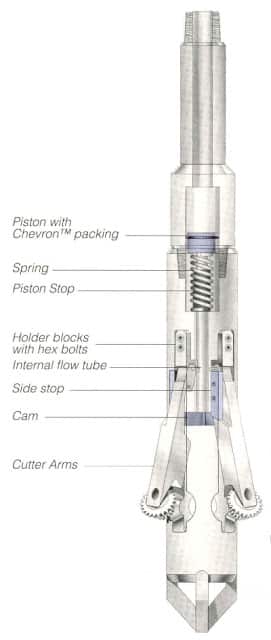

Drilling Under Reamers Components

Drilling under reamers types is composed of a body connected to the Drill String and mobile parts (“arms,” “blocks,” or “blades,” typically 3 of them) retracted in the body during the descent and extended downhole for the reaming operation.

Under-reamers Types Applications

Underreaming is primarily used to allow a wider clearance for running and Casing Cementing Job correctly, either due to restrictions (swelling shales, tortuosity) or to be able to run a larger casing size. It is commonly used for offshore drilling operations, exploration wells, extended reach drilling, or to increase the size of the production casing liner (One of the Types Of Casing). Under reamers, type is also required for directional casing-while-drilling (or “drilling with casing”) services to allow the directional BHA to be retrieved through the casing, either at the end of drilling or when a change of equipment is needed.

Under reamers Types

Underreamer Type had three main types:

- “Roller-cone” type under reamers, based on roller cone cutters technology, were often plagued by low reliability and limited bottom hole time.

- “hinge-and-pin” PDC

- “block-type” PDC, commonly used today, is suitable for reaming-while-drilling operations.

Drilling Roller Reamers

Roller reamers significantly improve performance with chronic drilling stick-slip or bit whirl-induced boreholes, which are the main reason for limiting drilling in hard formation and extended reach wells. And also for mud conditioning the borehole. Popular hole sizes for wellbores range from 5″ to 26″ in diameter. The size of the circulation path through the reamer body ranges from 1 1/2″ to 3 1/4″ in diameter. The body size on the necks beyond the area where the rollers are mounted typically ranges from 4 1/8″ to 11″ in diameter. This latter size will generally be the same as the Drill Collar. Body links usually range from 4′ to 8′.

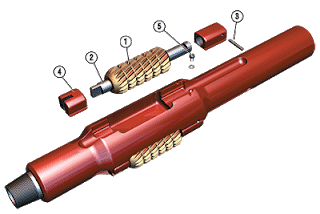

Roller Reamer Type Components

Most roller reamer types have three rollers equally spaced in a single transverse section. Such roller-reamers are referred to as “3-point reamers”. When two sets of three rollers spaced apart longitudinally are used, the roller-reamer is called a “6-point reamer”. However, large-diameter roller reamers may have more than three rollers in one transverse section. Let’s get an example of the JA Roller Reamer Type.

- Cutters

- Reamer Pin – A large diameter pin. The reamer pin is prevented from rotating by the engagement of the end of the pin with a slot in the body-bearing block.

- Cross Pin – This drive-fit cross-pin arrangement safely retains the central reamer pin and reamer cutter while providing a safety locking device.

- Drive-Fit Body Bearing Blocks – Blocks properly position the cutter in the body to cut a full-gauge hole. Blocks are readily changeable by the drilling crew.

- Socket Head Cap Screws and Lock Washers – Included as a secondary locking device for the reamer pins on each body for hole sizes 6 inches and larger.

Drilling RFID Reamers Types

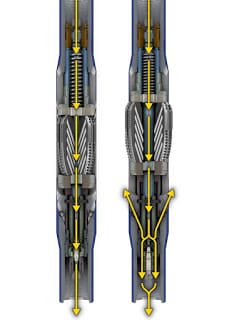

An RFID reamer types Mechanism uses radio-frequency identification (RFID) technology to activate the reamer. The electronically activated reamer provides increased flexibility for hole-enlargement-while-drilling (HEWD) operations. Weatherford’s RipTideTM RFID is inserted into the Drill Pipe ID at surface level and carried downhole in the drilling fluid. An electronic reader on the tool’s controller interprets instructions embedded in the tags to unlock the controller, thereby permitting the cutter blocks to extend fully from the reamer body. A surface-level pressure gauge confirms that the tool is in the open position. RFID features enable operators to activate and deactivate the tool while drilling or tripping.

Specific benefits RFID technology offers include:

- Prevents activation of the cutter blocks during jarring operations, significantly reducing the risk of getting the reamer stuck in the hole and incurring nonproductive time as a result;

- It helps protect the casing and the tool’s cutting structure from damage while cleaning the hole at full circulation and rotation;

- Multiple drilling reamers, which can be independently controlled, are permitted in tandem.

Drilling Near-Bit Reamers Type

Near Bit Reamer (NBR) can drill oversized holes. It is designed to enlarge the hole while drilling. They have been used in conventional Mud Motor and rotary steerable directional assembles.

Near-Bit Reamer Type Applications

- It will be economically wise to resolve many costly well problems in high-cost deep wells using Near-Bit Reamer Type. These problems compromise hole quality, such as moving salts or shale, cuttings bed buildup, and excessive cake formation.

- Also, to enlarge the hole size beyond the Drilling Bit size.

Usually, after drilling with the Near-Bit Reamer Type, it is necessary to perform back reaming, and it is more favorable to do it on the casing shoe. However, success in producing a larger annulus diameter reduced, and in some cases eliminated, the need for back reaming has been achieved. This will save drilling rig time and additional clearance to Run the Following Casing string types.

Expandable Reamers Type

Expandable reamers types were used to enhance efficiencies and decrease risk while drilling through formations with many problems, where wellbore stability is the main challenge.

The first concentric expandable reamer type was ball-activated. Once expanded, they could not be closed without stopping circulation. The reamer could be deactivated to allow circulation for better hole cleaning after reaming.

The advantages of the concentric expandable reamer type over its mechanical-arm predecessors included the attainment of a larger borehole size that could accommodate larger Bottom Hole Assembly BHA components, flexibility in pilot bit selection, higher flow rates, and the ability to ream a previously drilled hole or to back ream a hole after drilling. The drawbacks to traditional expandable underreaming systems. Activation cannot be confirmed.

In addition, the positioning of the expandable reamers type at 100 to 300 ft above the Drilling Bit means that the equivalent portion of the hole, known as a rat hole, won’t be enlarged without a special trip that will require 1 to 2 days which may cost from USD one million USD to 2 million USD.

Matching Bit and Reamer

Reamers and Drilling Bit should be matched for cutter size and aggressiveness (depth of cut) to balance loads more closely while drilling through homogeneous formations. For example, suppose the Drilling Bit out-drills the reamer. In that case, some inner formation stresses may have been released when the reamer started drilling a new formation. In this situation, there is no Weight On Bit (WOB), and the weight is transferred to the reamer, which may damage the drilling reamer cutters. In addition, with no Weight On Bit (WOB), lateral and whirl drill string vibrations can damage the Bottom Hole Assembly BHA and rapidly compromise wellbore stability. Matching the Drilling Bit and Drilling Reamers can eliminate these risks.