Wellbore Instability Definition

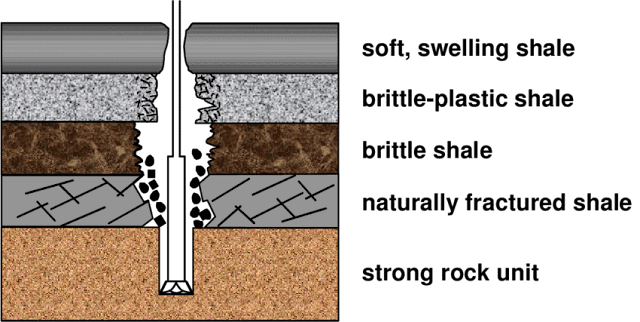

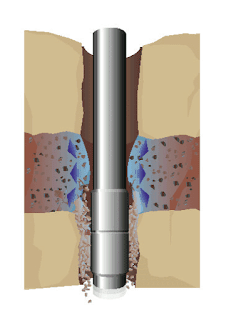

Wellbore or borehole instability is the undesirable condition of an open hole interval that does not maintain its gauge size and shape and/or its structural integrity.

The Main Causes Of Well Bore Instability:

- Unconsolidated Formation

- Overburden Stress / Mobile Formations

- Fractured Formation

- Naturally Over Pressured Shale

- Induced Over Pressured Shale

- Reactive Shale

- Tectonic Stress

How Unconsolidated Formations Cause Wellbore Instability?

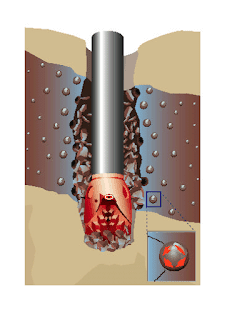

An unconsolidated formation falls into the wellbore because it is loosely packed with little or no bonding between particles, pebbles, or boulders.

The collapse of the formation is caused by removing the supporting rock as the well is drilled. This is very similar to digging a hole in the sand on the beach, the faster you dig the faster the hole collapses.

It happens in a wellbore when little or no filter cake is present. The un-bonded formation (sand, gravel, small river bed boulders, etc.) cannot be supported by hydrostatic overbalance as the fluid simply flows into the formation. Sand or gravel then falls into the hole and causes drilling pack off around the Drill String. The effect can be a gradual increase in drag over a number of meters or can be sudden.

This mechanism is normally associated with shallow formations. Examples are shallow river bed structures at about 500m in the central North Sea and in surface hole sections of land wells.

This type of wellbore instability normally occurs while drilling shallow unconsolidated formations.

Unconsolidated formations – Preventative Actions.

- This unstable formations need an adequate filter cake to help stabilize the formation.Seepage loss can be minimized with fine lost circulation material.

- If possible,avoid excessive circulating time with the Bottom Hole Assembly BHA opposite unconsolidated formations to reduce hydraulic erosion.

- Spot a gel pill before POOH.

- Slow down tripping Pipe speed when the Bottom Hole Assembly BHA is opposite unconsolidated formations to avoid mechanical damage.

- Start and stop the pumps slowly to avoid pressure surges being applied to unconsolidated formations.

- Control-drill the suspected zone to allow time for the filter cake to build up, minimize annulus loading and resultant equivalent circulating density.

- Use sweeps to help keep the hole clean.

- Be prepared for shale shaker, desilter and desander overloading.

A Passed Challenge In North Sea Unconsolidated Formations.

A method successfully used in the North Sea while drilling borehole instability unconsolidated formations, which is to drill 10 m, pull back to the top of the section and wait 10 minutes. Note any fill on bottom when returning to drill ahead. If the fill is significant then ensure the process is repeated every 10 m. It may be impossible to prevent the hole collapsing. If so let the hole stabilize itself with the Bottom Hole Assembly BHA up out of harm’s way.

Unconsolidated formations – Rig site indications.

- Increase in pump pressure.

- Fill on bottom.

- Overpull on connections.

- Shakers blinding.

Unconsolidated formations – Freeing Action.

Follow Pack Off / Bridge Stuck Pipe First Actions but be aware that the pressures (i.e. 500 psi, 1500 psi) will probably not be achievable in shallow formations.

What Is The Role Of Mobile Formations / Overburden Stress On Wellbore Instability?

The mobile formation squeezes into the wellbore because it is being compressed by the overburden forces. Mobile formations behave in a plastic manner, deforming under pressure. The deformation results in a decrease in the wellbore size, causing problems running Bottom Hole Assembly BHA’s, logging tools, and casing.

A deformation occurs because the mud weight is not sufficient to prevent the formation from squeezing into the wellbore. This kind of wellbore or borehole instability normally occurs while drilling salt.

Unstable Mobile Formations – Preventative Action

- Maintain sufficient mud weight.

- Select an appropriate mud system that will not aggravate the mobile formation.

- Plan frequent reaming/wiper trips particularly for this section of the hole.

- Consider bi-centre PDC Drilling Bits.

- Slow down trip speed before BHA enters the suspected area.

- Minimize the open hole exposure time of these formations.

- With mobile salts consider using a slightly under-saturated mud system to allow a controlled washout.

Unstable Mobile Formations – Rig site indications

- Overpull when moving up, takes weight when running in.

- Sticking occurs with BHA at mobile formation depth.

- Restricted circulation with BHA at mobile formation depth

Unstable Mobile Formations – Freeing Pack Off / Bridge Stuck Pipe

- Spot a fresh water pill if in a salt formation. (Consider the effect on well control and on other open hole formations ).

- If moving up, apply torque and jar down with maximum trip load.

- If moving down, jar up with maximum trip load.

- Torque should not be applied while jarring up.

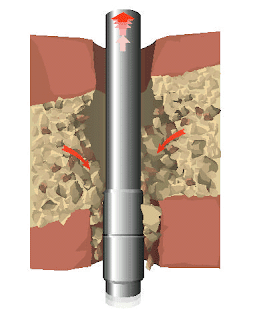

Unstable Fractured And Faulted Formations Can Also Considered As A WellBore Instability Problem

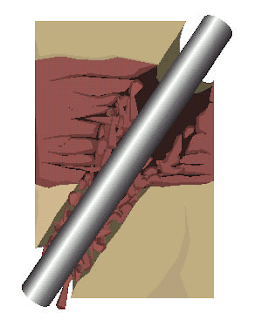

A natural fracture system in the rock can often be found near faults. Rock near faults can be broken into large or small pieces. If they are loose they can fall into the wellbore and jam the string in the hole. Even if the pieces are bonded together, impacts from the BHA due to Drill String vibration can cause the formation to fall into the wellbore.

This type of Pack off / Bridge sticking is particularly unusual as it can occur while drilling. When this has happened in the past, the first sign of this borehole instability problem has been the string torquing up and sticking.

There is a risk of sticking in fractured/faulted formation when drilling through a fault and when drilling through fractured limestone formations.

Unstable Fractured And Faulted Formations – Preventative Action

- Minimize Drill String vibration. Choose an alternative RPM or change the BHA configuration if high shock vibrations are observed.

- Slow down the trip speed before the BHA enters a suspected fractured/faulted area.

- Generally, fractured formations require time to stabilize. Be prepared to spend time when initially drilling and reaming prior to making significant further

progress. - Circulate the hole clean before drilling ahead.

- Restrict tripping speed when BHA is opposite fractured formations and fault zones.

- Start / stop the Drill String slowly to avoid pressure surges to the well bore.

- Anticipate reaming during trips. Ream fractured zones cautiously.

Unstable Fractured And Faulted Formations – Rig Site Indications

- Hole fill on connections.

- Possible losses or gains.

- Fault damaged cavings at shakers.

- Sticking can be instantaneous.

Unstable Fractured And Faulted Formations – Freeing Pack Off / Bridge Stuck Pipe

- If packed off while off bottom then follow Pack Off / Bridge Stuck Pipe First Actions. Otherwise JAR UP in an effort to break up formation debris.

- Use every effort to maintain circulation.

- Circulate high density viscous sweeps to clean debris.

- Spot acid if stuck in limestone.

Yes, Over-Pressured Shale Collapse Is A Wide Wellbore Instability Problem

A naturally over-pressured shale is one with a natural pore pressure greater than the normal hydrostatic pressure gradient.

Naturally over-pressured shales are most commonly caused by geological phenomena such as under-compaction, naturally removed overburden (i.e. weathering ), and uplift. Using insufficient mud weight in these formations will cause the hole to become unstable and collapse, that’s why it is a wellbore or borehole instability source.

This mechanism normally occurs in: Prognosed rapid depositional shale sequences.

Pressurized Shale Collapse – Preventative action

- Ensure planned mud weight is adequate.

- Plan to minimize hole exposure time.

- Rigorous use of gas levels to detect pore pressure trends.

- Use of other information to predict pore pressure trends (for example Dexp ).

- Once the shale has been exposed do not reduce the mud weight. It may also be the case that the mud weight will need to be raised with an increase in inclination

Pressurized Shale Collapse – Rig Site Indications

- Cavings (splintery) at shakers.

- Increased torque and drag.

- Gas levels, D exponent.

- Circulation restricted or impossible.

- Hole fill.

- An increase in ROP.

- Cuttings and cavings are not hydrated or mushy.

Pressurized Shale Collapse – Freeing

Follow Pack Off / Bridge Stuck Pipe First Actions.

Also Take Care Of The Induced Over-Pressured Shale Collapse

Induced over-pressure shale occurs when the shale assumes the hydrostatic pressure of the wellbore fluids after a number of days of exposure to that pressure. When this is followed by no increase or a reduction in hydrostatic pressure in the wellbore, the shale, which now has a higher internal pressure than the wellbore, collapses in a similar manner to naturally over-pressured shale and off course cause a wellbore instability problem.

This mechanism normally happens:

- This type of borehole instability happens in WBM.

- After a reduction in mud weight or after a long exposure time during which

the mud weight was constant. - In the casing rat hole.

Induced Over-Pressured Shale Collapse – Preventative action

- Non Water Based Mud prevent inducing over-pressure in shale.

- Do not plan a reduction in mud weight after exposing shale.

- If cavings occur, utilise good hole cleaning practices.

Induced Over-Pressured Shale Collapse – Rig site indications

- Cuttings / cavings show no sign of hydration.

- Cavings (splintery) at shakers.

- Tight hole in casing rat hole

- Increased torque and drag.

- Circulating restricted or impossible.

- Hole fill.

Induced Over-Pressured Shale Collapse – Freeing

Follow Pack Off / Bridge Stuck Pipe First Actions.

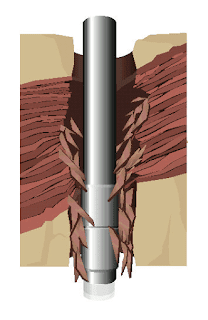

Finally, The Powerful Source Of The Wellbore / Borehole Instability Problem, Reactive Formations

An unstable water-sensitive shale is drilled with less inhibition than is required. The shale absorbs the water and swells into the wellbore. The reaction is ‘time dependent’, as the chemical reaction takes time to occur. However, the time can range from hours to days.

This borehole instability mechanism normally takes place :

- When using WBM in shales and clays in young formations.

- When drilling with an incorrect mud specification. Particularly, an insufficient concentration of inhibition additives in OBM and WBM such as salts (KCl, CaCL), glycol and polymer.

Reactive Formations – Preventative action

- Use an inhibited mud system. Maintain the mud properties as planned.

- The addition of various salts (potassium, sodium, calcium, etc. ) will reduce the chemical attraction of the water to the shale.

- Various encapsulating (coating) polymers can be added to WBM mud to reduce water contact with the shale.

Monitoring mud properties is the key to detection of this problem. - Open hole time in shale should be minimised.

- Regular wiper trips or reaming trips may help if shales begin to swell.

- The frequency should be based on exposure time or warning signs of reactive shales.

- Ensure hole cleaning is adequate to clean excess formation i.e. clay balls, low gravity solids etc.

Reactive Formations – Rig site indications

- Hydrated or mushy cavings.

- Shakers screens blind off, clay balls form.

- Increase in LGS, filter cake thickness, PV, YP, MBT.

- An increase or fluctuations in pump pressure.

- Generally occurs while POOH.

- Circulation is impossible or highly restricted.

Reactive Formations – Freeing

- POH slowly to prevent swabbing.

- Follow Pack Off / Bridge Stuck Pipe First Actions

At Last, Tectonically Stressed Formations

Wellbore instability is caused when highly stressed formations are drilled and there exists a significant difference between the near-wellbore stress and the restraining pressure provided by the drilling fluid density.

Tectonic stresses as a cause of wellbore instability, build up in areas where rock is being compressed or stretched due to movement of the earth’s crust. The rock in these areas is being buckled by the pressure of moving tectonic plates. When a hole is drilled in an area of high tectonic stresses the rock around the wellbore will collapse into the wellbore and produce splintery cavings similar to those produced by over-pressured shale.

In the tectonic stress case, the hydrostatic pressure required to stabilize the wellbore may be much higher than the fracture pressure of the other exposed formations.

This mechanism usually happens in or near mountainous regions.

Tectonically Stressed Formations – Preventative action

- Plan to case off these formations as quickly as possible.

- Maintain mud weight within planned mud weight window.

- Well bore instability shows itself as a hole cleaning problem. If possible drill these formations in smaller hole sizes. This will minimise the impact of a hole cleaning problem.

- Ensure that the circulation system is capable of handling the additional volume of cavings often

associated with this mechanism. - Use offset data to establish optimum inclination and azimuth as these are key factors in reducing the extent of the problem.

Tectonically Stressed Formations – Rig site indicators

- Pack-offs and bridges may occur.

- Cavings at the shakers (splintery).

- Increase torque and drag.

- If stuck, circulation is likely to be impaired or non-existent.

- Increase in volume of returns at the shakers relative to the hole volume drilled.

Tectonically Stressed Formations – Freeing Pack Off / Bridge Stuck

See Pack Off / Bridge Stuck Pipe First Actions

You could also visit the awesome presentation and download it to be in your records

Practical Approach to Solving Wellbore Instability Problems

Reference:

- Drilling Handbook For Stuck Pipe For Drillers