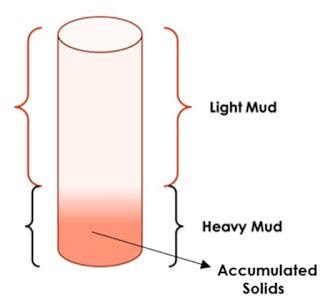

When weighted muds are used in highly deviated wells, there is the tendency for barite to settle towards the low side of the hole, creating a stratification of lighter mud on top and heavier mud on the bottom. The heavier layer then begins to migrate downwards along the length of the hole due to the gravitational pull. This continuous movement of the mud prevents the development of more substantial gel strengths, compounding the settling problem. Variations in the hydrostatic head can cause formation fracturing with accompanying loss of circulation, possibly leading to an influx of formation fluids. Barite sag can be troublesome and time-consuming to correct and, therefore, very expensive. While sag is more of a problem in angled wells, it has also been observed in vertical wells.

How Barite Sag Is Initiated

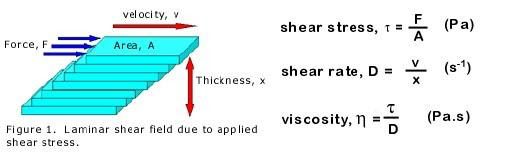

The mechanism by which barite sag develops is not clearly defined but is believed to occur under low shear rate conditions. In laminar flow, shear is generated because fluid layers near the wall or pipes move slower to that further from the wall or pipe. The velocity of a layer relative to the layer next to it is called the shear rate.

The shear rate is defined as the velocity gradient measured perpendicularly to the fluid flow and is usually reported in reciprocal seconds (sec^-1).

The commonly held belief is that in an inclined wellbore, low shear rates sufficiently interfere with the gel structure of mud to allow downward movement of the coarser barite particles. The motion of these particles displaces lighter fluid up toward the high side of the hole. The perception is that the range of shear rates required to set up this behavior is predominant underneath an eccentric pipe. Some doubts have been raised regarding this area of the well’s geometry being the only contributor to sag. It is difficult to understand how occasionally large mud weight reductions can be generated from such a relatively small volume of mud.

Sag Mechanism

It seems more probable that a sag mechanism can exist within the total volume of the mud, with the “settlement” of barite moving to the low side of the hole. Barite sag is intensified at the low side by the very low velocity in that well area. Flow loop testing has proved that a sag mechanism can be set up at shear rates as high as 95 sec^-1.

In reaching these conclusions, many wells were analyzed, and only one incidence was found where barite sag was reported while drilling. This occurred while sliding and was corrected by short periods of rotation. All other reported instances of barite sag coincided with the running casing, particularly after thinning the mud.

Indications of Sag

Barite sag will not be seen in the surface tanks. It can only be detected by frequently checking the fluid density at the flow line.

The most critical time for Barite sag is during periods of relative inactivity when the fluid has had minimal agitation, times such as

- First, When sliding (directional drilling),

- Second, While running casing/casing liner (One of Types Of Casing)

- Third, While logging in.

When circulation is resumed after these activities, the density at the flow line must be checked continually, and the data recorded. All results must be adjusted to compensate for fluctuations in temperature using a temperature chart located at the shale shakers.

Sagging Symptom

A symptom of barite sag would be when density checks at the shakers see a drop in density, followed by an increase, to be followed eventually by mud weight of the correct density. This idealized cycle of mud weights seen at the shale shakers may not be seen as new barite additions could mask it.

Historical data has shown that weight measurements indicating heavy mud are not always seen to follow light mud and that the correct density is then only achieved when fresh barite is added. Heavy mud has been seen on some occasions.

Whether or not heavy mud is measured on any particular occasion may depend on rig activity. For instance, the barite may have settled on the low side and circulated without rotation, may not reintroduce back into the circulating mud, and not be seen at the surface. If this is the case, if heavy mud is to be seen, it may happen after trips with pipe (check also tripping pipe procedures) rather than when, for instance, running casing. It is difficult to envisage a sag-related mechanism that could result in heavy mud in the annulus without light mud somewhere in the circulating system. However, the absence of reported light mud may be explained by heavy slugs pumped before pulling out of the hole.

Investigated instances of sag have shown telltale symptoms, with the earlier arrival of light mud at the shakers, usually as soon as the pumps were turned on, followed by a gradual increase in density until the correct mud weight, or on occasion, some heavy mud has been seen.

Barite Sag Causes

Incidents of barite sag have been reported on highly extended or deviated wells on numerous occasions since the mid-1980s. Sag can occur in either dynamic or static conditions and may be indicated by variations in mud weight when circulating.

Hole conditions that may influence sag tendency are:

- Temperature – Higher temperatures increase sag tendency.

- Hole angle – Sag tendency is increased in deviations >30°.

- Static time – Although sag can occur under dynamic conditions, its effects are usually not apparent until the mud system has been static for a considerable period – after tripping, logging, or running casing.

- Semi-Static conditions – Minor movements which break gels, such as tripping pipe or running wireline logs, increase sag tendency. Slow circulation rates can create conditions likely conducive to sag.

- Hydrocarbon influxes can affect mud rheological properties

Mud properties that influence sag tendency are:

- Rheology, Surface vs. Downhole – Sag occurs even when traditional rheology measurements taken under surface conditions (high YP, PV, and Gels) indicate that it should not. When measured under downhole temperature and pressure conditions on a FANN 70 viscometer, muds that exhibit sagging behavior in the well usually demonstrate different rheology and suspension characteristics than their normal surface measurements. The degree of variance between surface and downhole rheology is to some extent, a measure of the stability of the mud system. The less variance, the more stable the mud system. A key factor that affects the variance in rheological behavior in an inverted emulsion mud system is the type of base oil used. The base oil’s viscosity versus temperature behavior is critical.

- Mud weight – Variations in density will be more pronounced at higher mud weights.

5 Ways to Prevent and Cure Barite Sag

1 Rheology

The Hershel- Bulkley/Yield-Power Law model better correlates with lab-measured sag coefficients since it more accurately describes fluid behavior at a low shear rate.

- A fluid Tau0 (yield stress) of 7 to 8 lbs/100 sq ft will normally reduce the static sag in field mud to acceptable levels.

- Check the mud rheology at elevated temperatures (e.g., 120°F) to indicate downhole rheology.

- Use FANN 70 testing before the well to optimize mud product concentration for stable downhole mud rheological properties.

- Testing with special apparatus called the High Angle Sag Tester (HAST) simulates downhole conditions and shows whether a fluid requires special additive treatments to improve suspension properties.

- Additions of DURATONE have been shown to reduce sag tendency.

2 Mud Weight

Maximum and minimum mud weights should be recorded when circulating bottoms up after trips in deviated wells, especially after logging. It is important to maintain uniform mud weight throughout the circulating system. Efforts should be made to treat and equalize any imbalance as quickly as possible.

If the equivalent circulating density (ECD in Drilling) is close to the fracture gradient, this could require circulating until the density is homogeneous before resuming drilling operations.

Note:

When using inverted emulsion muds in high-temperature wells, it is important to measure the temperature at which the mud weight is recorded to avoid misinterpretations between barite sag and thermal expansion/contraction effects.

3 Oil/Water Ratio

HAST tests have shown that decreasing the oil/water ratio decreases sag tendency.

4 Materials and Systems

The best treatment to prevent barite sag is to ensure sufficient gels and low-end rheology.

- In Water Based Mud this can be achieved with several products, including AQUAGEL and AQUAGEL GOLD SEAL, and polymers such as BARAZAN PLUS.

- In Oil Based Mud and synthetic muds, low-end rheological modifiers such as RM-63, in conjunction with GELTONE and SUSPENTONE (a suspension agent for invert emulsions), have been used successfully to prevent barite sag.

5 Drilling Practices

- Modify operations to maintain sufficient annular disturbance through adequate circulation and rotation rates to limit periods of low shear. Any operation that induces low shear (slow circulating rates, running casing, or running logs) has the potential to initiate sag. Laboratory work has confirmed that the shear rates generated when running casing are of the right magnitude to induce barite sag in an inclined borehole.

- At the planning stage of wells identified as having a high sag potential, consideration should be given to rotary drilling rather than sliding. Sag is most likely to occur when the drill pipe is not being rotated while low-shear conditions are being generated. This is particularly important for 60-75 degrees wells where even high annular velocities may not eliminate sag. Minimize sliding in these intervals. Pull back one stand and rotate at high rpm after extended periods of sliding to reintroduce heavy mud from the low side of the hole into the main body of the mud.

- Avoid pumping base oil slugs to “wake up” the MWD tool, particularly immediately before a trip. The oil can thin a significant portion of the mud and promote conditions conducive to barite sag.

- In situations where mud weight is close to the fracture gradient, minimizing the potential increase in bottom hole pressure due to sagged mud is important. After a trip, the potential risk of circulating bottoms up in the tangent section is that some light mud can be circulated out of the hole while being replaced by mud from the suction pit at the correct density. The heavier, sagged mud in the deeper part of the tangent section coupled with the mud of correct density now in the upper part of the hole could cause increased bottom hole pressures initiating downhole losses.

- Conversely, in situations where the pore pressure is close to mud weight and barite sag is suspected, minimize the effect of low-density mud on hydrostatic by staging the drilling assembly into the hole, breaking circulation, and circulating bottoms up at several points while running back in. If the fluid has sagged, the effect on the annular hydrostatic pressure will be reduced if the out-of-balance column is not circulated out all at once.

- If excessive changes in mud density are observed at the surface, stop and condition the mud. Allow a minimum of two total mud circulations to enable effective chemical treatments and to eliminate all density fluctuations.

Barite Sag Study

Barite Sag Study conducted in MI Swaco’s lab in Vung Tau. The video shows the mud samples coming out of the ageing cells after 24 hrs of static ageing at 160 degC. There are 5 samples:

- 1 x untreated rig sample of the active mud,

- 1 x treated rig sample with 2 ppb Surewet + 0.5 ppb Bentone,

- 1 x treated rig sample with 3 ppb Onemul + 0.5 ppb Bentone,

- 1 x treated rig sample with 3 ppb Onemul + 0.2 ppb Versamod

- 1 x treated rig sample 2 ppb Onemul + 0.2 ppb Versamod.

Onemul is a primary emulsifier and Surewet is a wetting agent. Bentone and Versamod are both SBM viscosifiers. The mud densities from the very bottom of the ageing cell were as follows (note base mud wt = 17.7 ppt at 30 degC):

- Untreated sample: unmeasurable

- 2 ppb Surewet + 0.5 ppb Bentone: 18.25 ppg

- 3 ppb Onemul + 0.5 ppb Bentone: 18.31 ppg

- 3 ppb Onemul + 0.2 ppb Versamod: 17.96 ppg

- 2 ppb Surewet + 0.2 ppb Versamod: 18.00 ppg

The video demonstrates the vast improvement of the mud condition of the base rig mud sample after being treated with emulsifiers and small amounts of viscosifier.

Other