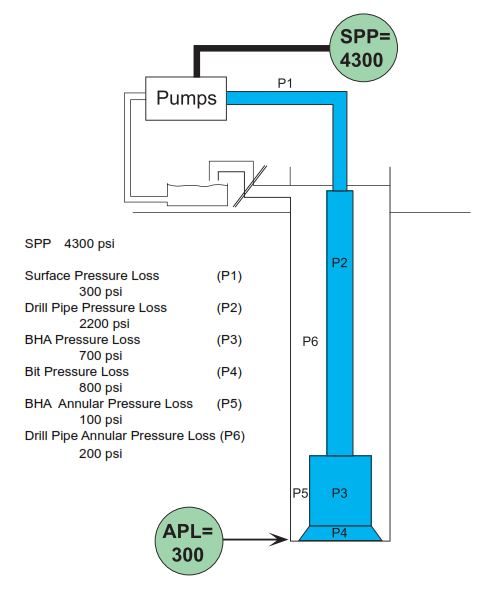

We define annular pressure loss or APL as the pressure lost while circulating drilling mud in the annulus. This loss is mainly due to frictional forces between the mud, borehole wall, and drill string.

What Is The Pressure Loss?

Pressure is required to circulate mud around a wellbore. This pressure is necessary to overcome the following:

- Internal Friction of the fluid moving past itself.

- Back-pressure as fluid flows through a restriction

- To turn PDM stator, Turbine and MWD tool impellor.

The effort required to overcome the resistance to flow is called pressure loss. This pressure loss is measured by the standpipe pressure gauge. To have more info, please visit the pressure loss calculation.

Circulating Pressure loss is dependent upon the following:

- Flow rate

- Drilling fluid properties – Viscosity (PV and YP)

- Geometry of flow path – Pipe/annular dimensions

Increases in either the flow rate or the viscosity cause an increase in pressure loss. An increase in the annular clearance due to a larger hole ID or a smaller pipe OD reduces pressure loss.

Components Of Pressure Loss

Drilling professionals can split the Circulating Pressure Loss into two main components:

- Drill String Internal Pressure Loss

- Annular Pressure Loss.

We are generally concerned with the pressure loss affecting the Equivalent Circulating Density. (NB. If reverse circulating, the internal pressure loss acts upon the bottom of the hole, not the APL, and affects the Drilling ECD. The internal pressure loss is considerably greater than the annular pressure loss, so great care must be taken in these circumstances.)

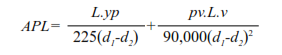

Annular Pressure Loss Calculation

The APL can be calculated using various equations. One such equation is:

Where:

- D = depth in ft,

- PV/YP = plastic viscosity in cp and mud yield point in lb/100 ft2

- d1 = Hole ID, inch

- d2 = String OD, inch

- v = annular velocity, ft/sec

- L= length

The Annular Pressure Loss can be calculated with moderate accuracy, but this often ignores some essential factors which affect the APL:

- Solids loading in the annulus.

- Speed of drill string movement.

- PV and YP variations (sag and temp).

- Unknown changes in annular dimensions, i.e., washouts or restrictions.

- Increases in drill string component ODs, e.g., Enhanced performance drill pipe (check API drill pipe Specifications), and drill string protectors.

Factors Affecting APL

- Annular Velocity: Increasing annular velocity directly increases frictional forces in the annulus, increasing APL.

- RPM: increasing RPM will increase the APL.

- Annulus cross-section area: a reduction in the cross-sectional area will create more friction during circulation, increasing the APL.

- Mud Rheology: Increasing mud viscosity will increase friction loss during circulation, increasing annular pressure loss.