Casing repair is not exactly a drilling fishing job, but if the casing collapses, splits, or parts you’re fishing skills can help you repair the casing. Casing repair involves using a variety of tools downhole.

Each casing failure must be evaluated based on the specific conditions of the failure before a method of repair can be determined. This article will help you analyze the casing failure, and it will provide instructions on repairing split or collapsed casing.

Casing Failure & Repair

Casing failure can occur for a variety of reasons, but the most common are:

- earth shift or subsidence

- corrosion or erosion

- excess pressure: internal or external

- drill pipe wear

- rod wear while producing the well

- improper makeup when casing running

- backed off shoe joint

- fishing operations inside the casing

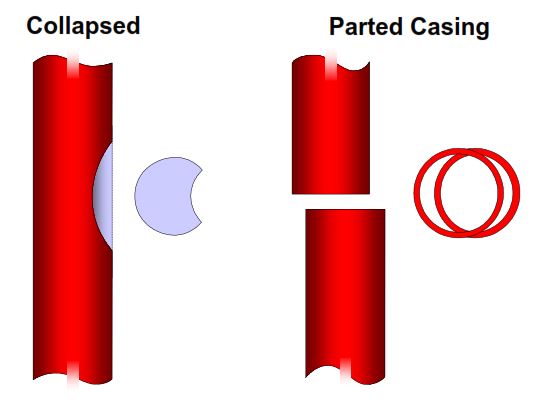

Types of Failure

- Casing leaks are the most common failure. The causes are improper makeup, drill pipe wear, running abrasive drilling stabilizers in the casing, corrosion or erosion, or mechanical wear while fishing or producing the well.

- Split or burst casing occurs from many causes including bumping the cement plug too hard while cementing, applying excess internal pressure, or high tensile loading.

- The same forces that are applied to leaks cause collapsed casing and will require repair. Anything that reduces the wall thickness, such as wear or corrosion increases susceptibility to collapse.

- The parted casing is caused by improper casing design, poor operating procedures or a mechanical failure, and usually parts at a connection.

Identifying The Problem Is The First Step

In order to repair the casing, you need to determine the:

- Depth of the failure

- Type of failure.

- Whether the casing is cemented at the failure or can be retrieved

Collapse

If you suspect that your casing has collapsed:

- Measure the point at which the drilling bit stops or the string drags (Torque and Drag In Drilling).

- Run a lead impression block to get the dimensions of the collapse.

The lead impression block is pliable and will make a mold of the failure spot.

Split

If you suspect that your casing has split:

- Run an RTTS tool to determine the depth of the casing split that need repair.

- Run a casing inspection log to determine the thickness of the casing wall at the split.

- Run a downhole video camera to get pictures of the split.

RTTS tool

The RTTS tool will tell you the depth at which the split occurs.

- Set the tool.

- Pressure up in the annulus.

| IF the pressure… | THEN the RTTS tool is positioned… |

| remains static, | above the split. |

| drops, | below the split. |

Casing Inspection Log

- Mechanical calipers examine the inner pipe surface and can detect holes, splits, a swelled or collapsed section, or perforations.

- Electromagnetic tools examine and discriminate the inner and outer pipe surface.

- Acoustic devices identify the pipe ID and wall thickness.

All these tools require a prior bit and scraper run to clean the ID of the pipe then proceed with casing repair operations.

Downhole video camera

DHV International supplies two types of downhole video camera systems:

- The fiber optic system

- The hawk Eye system.

The fiber optic system provides continuous, full-motion video. This system includes a 7/32″ OD fiber optic cable that sends real-time video images to the surface from as far as 14,000′ below the surface. The camera must be run using the fiber optic cable. It will not work from a regular electric wireline. The camera has a temperature limitation of 250 degrees F.

The Hawk Eye system provides static images, like snapshots, that are stored on videotape. The camera can be run on any electric wireline. For both downhole video systems, a lens surfactant keeps most oil and mud off of the camera lens, but to get the clearest images, you should still pump clear fluid (water) downhole before filming

Determining The Type of Casing Repair

Collapsed Casing Repair

| If the casing is… | THEN restore the casing ID to its original dimensions using a… |

| slightly collapsed, | casing roller. |

| more collapsed, | Casing swage. |

| not able to be rolled or swaged, | string mill, and a casing repair tool. |

Split Casing Repair

| If the casing is… | THEN repair the break using a(n)… |

| not cemented above the split, | external casing patch. |

| cemented above the split, | internal casing patch. |

| parted | string mill and a casing repair tool. |

Equipment Used for Casing Repair

There is a variety of equipment used to perform the necessary repair for the casing according to the type of failure mentioned above. We shall discuss them separately and their running procedures through the following articles: