The main application of a junk mill as a milling tool (milling in drilling) is clearing the junk for shortening tubular, bit cones, and general junks. Mills and boot baskets go hand-in-hand while oil and gas fishing operations. It is common to use Boot baskets with these mills because they collect the pieces of the fish that the mill grinds up.

Types Of Junk Mill

The following are examples of types of mills that are used for eliminating junk:

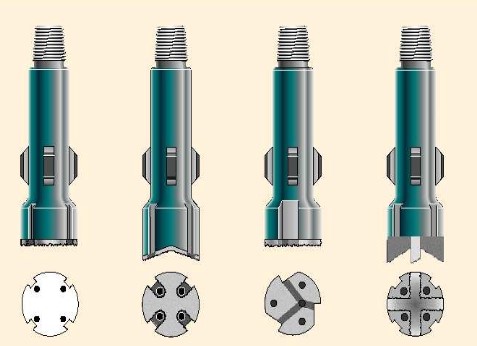

- insert type mill

- crushed tungsten carbide mill

- skirted flat bottom or concave type mill

- blade type mill

- cone buster mill

- cement mill.

| Mill Type | Commonly used for milling… |

| insert type | pipe/tools anchored securely in the wellbore. Caution: Chatter, vibration, or loose junk are detrimental to the inserts. |

| crushed tungsten carbide mills | almost anything, except in hard abrasive formations. |

| skirted flat bottom or concave type mill | flared or burred top of fish prior to engagement with an overshot. Note: Because the skirted mill is stabilized and the fish is contained within the skirt, it cannot slip off |

| blade-type mill | junk or cast iron material which will break up. |

| flat bottom cone buster mill | bit cones or other pieces of junk. These mills work well when milling drillable packers, bridge plugs, cement retainers, and cement. Note: Important characteristics of cone buster mills include that they can be furnished with: 1- large circulation ports which improve mud circulation for cooling and cutting removal. 2- smooth outside diameter along with stabilizer pads designed to be run inside casing. |

| cement mills | cement |

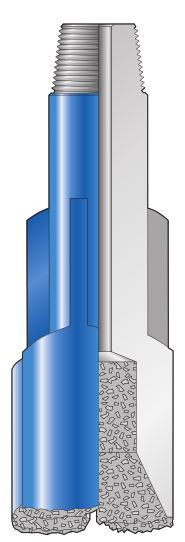

Tungsten Carbide Inserts Junk Mill

Carbide insert mills give their optimal performance under very specific circumstances and fail miserably in others. Some basic criteria that one should consider when determining whether to use a crushed carbide mill or a carbide insert mill:

- Is the fish tubular? Insert mill perform best milling tubular.

- The cementation condition of the fish? Insert mill performs best in some cases such as cemented tubular and casing.

- Is the fish loose junk? Insert mill does not perform well with loose junk such as bit cones, which should be left to the standard concave type junk mill.

Tungsten carbide insert mill generally doe not perform well when the fish can move. The inserts tend to shatter and break when there is “chatter” (i.e., excessive drill string vibration or jumping). The best applications for tungsten carbide insert mill is when the tubular is cemented in place (cementing in drilling).

Crushed Tungsten Carbide Junk Mill

Selecting the best mill for a specific task is not always straightforward. This is due to many different mill styles are available. And also, some have multiple purposes, and others are suited for limited, specialty jobs.

As an example, Junk & flat-bottomed mill is suitable for handling solid junk, cemented junk, cement squeeze tools, packers, and bridge plug milling. Normally, we can spud them as required when junk rotates, and are generally solid, heavy-duty mills with stabilized mill heads or body stabilizers.

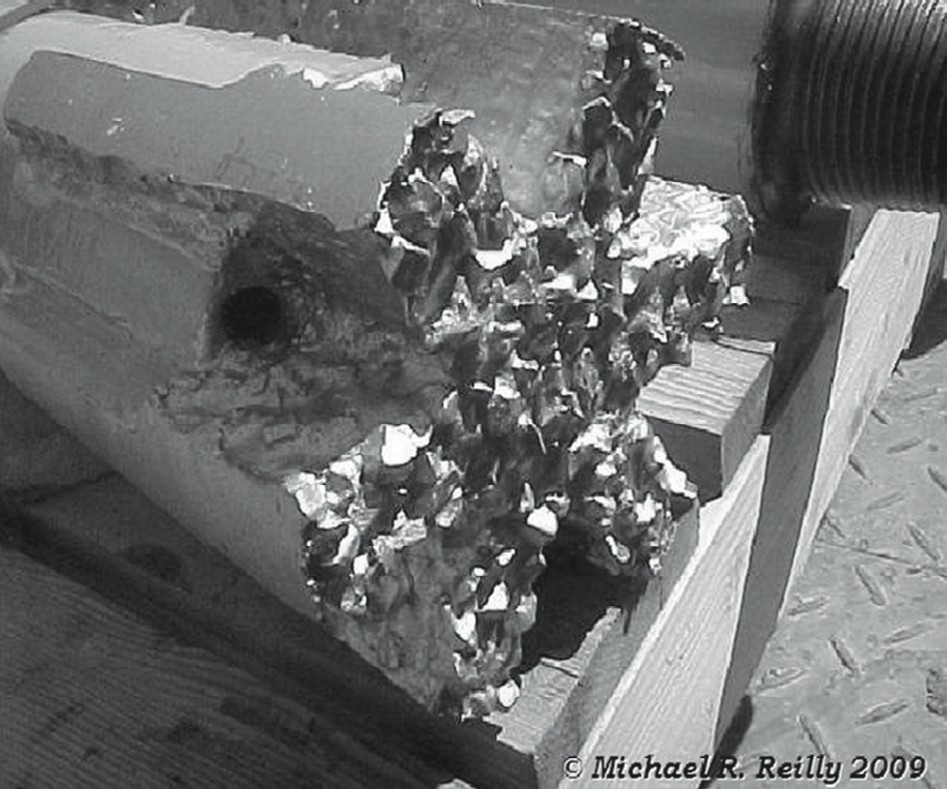

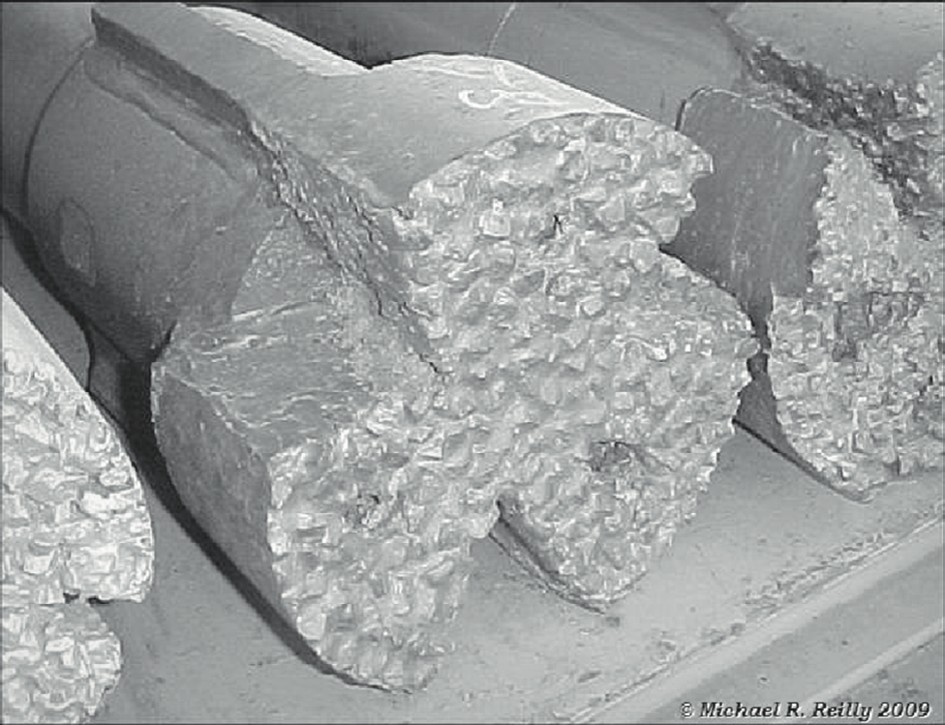

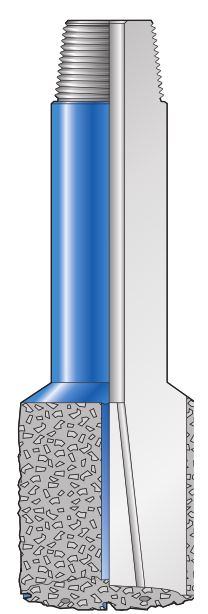

Cone Buster Mill

Manufacturers supplied the buster mill with carbide to be applicable for milling bit cones, loose junk, and dressing off tubing. So, we can say that the major advantage of the tool concave design is that it keeps the fish centered, which will maximize the mill efficiency.

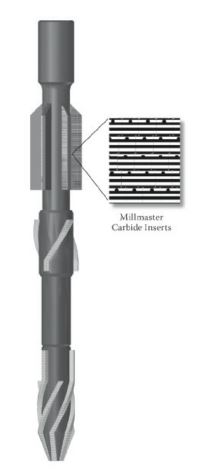

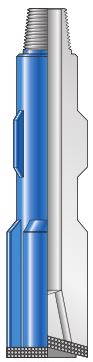

Metal Muncher Mill

Have you thought before about milling cemented drill collars, tubing, or drill pipe? The metal muncher design gives you a solution to such problems. It is effective and quick as it has tungsten carbides and backing. So, once the wearing of its inserts occurs, the new inserts raw are exposed and the milling continues.

Generally, we use it for milling stationary subjects. Its milling rate (more than 30 ft/hr for tubing) may encourage you to choose the milling option over the fishing trials.

Piranha Mill

If you are afraid of coring and need a long-life mill, you may choose this design for milling cemented pipes or when there is a large amount of junk. This is because of its offset center & Deep V design.

Hollow Mill Accessory

This tool is not really a mill, it is just an accessory. Sometimes, due to jet cuts or broken tools, while drilling, you may need to dress it off and then try to fish which will take two trips with more additional time and cost. So, you may think about it if you want to mill and retrieve flared tops of the fish.

Simply, install it between the overshot bowl and guide. After you dressed off the oversizes or flared fish, lower the overshot and start the engagement process.

Milling Guidelines

Some important guidelines for utilization of junk mill are:

- Provide adequate circulation to flush the cuttings and cool the mill.

- A junk basket must be run directly above the mill to catch the metal cuttings.

- Always mill by torque and not by weight. If the mill is producing torque and making progress, then the weight applied to the mill is sufficient.

Most people run too much weight on mills. That is why you should know that the standard rule of thumb is not to exceed 1,000 pounds per OD inch of the mill.

Note: Mills with stabilizer pads should be used inside the casing.

IF you are milling pipe that causes the drill string to bounce and vibrate, THEN consider using a Bowen Shock Sub (Drilling Subs) to cut down on Bottom Hole Assembly vibration (BHA Vibrations).

Calculating Milling Rates

The manufacturer specifies the milling rates for the carbide junk mill in Surface Feet Per Minute (SFPM). It is a must to convert the surface feet per minute to revolutions per minute (RPM) because the operator does not have a way to measure surface feet per minute.

The rpm may be derived from the SFPM by multiplying the mill diameter by the milling RPM. This result is then multiplied by a constant, 0.262. For example, a certain mill’s diameter is 4.5″ and the milling rate in RPM is 120.

You would calculate the SFPM in this way:

= mill diameter x milling RPM x 0.262

= 4.5 x 120 x 0.262 = 142 SFPM.

As you can see, table 2 lists some standard milling rates. We can compute other rates by converting the milling rates in revolutions per minute to surface feet per minute.

| Mill | SFPM |

| crushed carbide mills | 150 to 200 |

| carbide insert mills | 150 to 300 |