The junk basket is very useful if you want to collect small pieces of loose junk in the basket. They are doing that easily due to the reduced annular velocity at the junk basket opening. Baskets are also good for picking up relatively small junk such as steel cuttings. Also, are good in carbide inserts drilling bit teeth, and ball bearings.

Identically, you can run this type of fishing tool directly above a bit or junk mill. In addition to that, you can run them in tandem 2 or 3 above each if necessary. But, it will only work with direct circulation.

Remember: Spinning junk basket frequently causes the fish to be lost back into the hole.

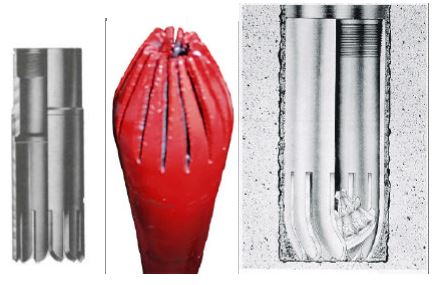

Global Junk Baskets

The main application for the globe-type junk basket is to recover any type of small object in the wellbore. But, the successful operation of the tool requires cutting a core from the formation. Any junk will be recovered above the core. Professionals recommend the Globe Type Junk Basket when performing fishing operations in soft to medium formations. (with a drilling rate above 15 feet per hour).

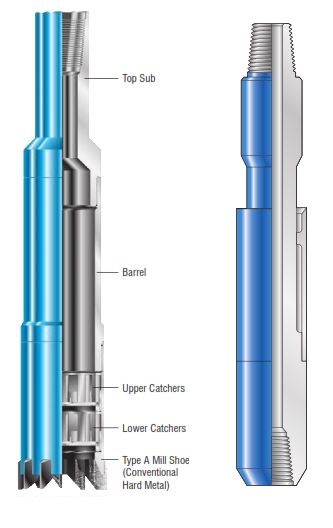

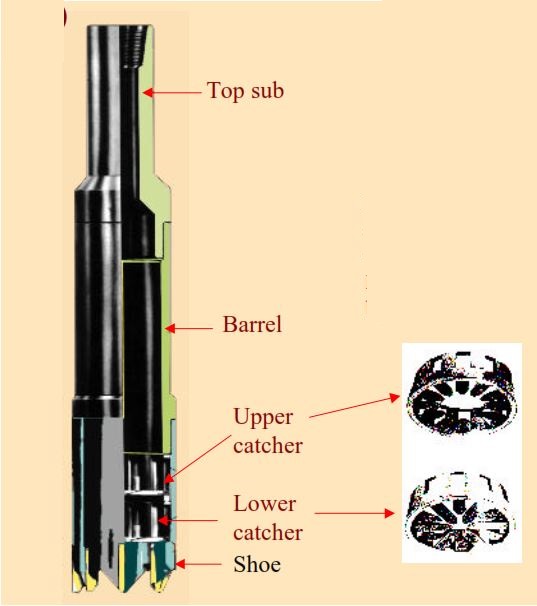

The Bowen Itco/Globe basket consists of a top sub, barrel, and tungsten carbide milling shoe. Also, inside are two manganese bronze catchers that are free to rotate.

Running & Operations

| Step | Action |

| 1 | Begin rotating and circulating about 30 feet off bottom with a medium pump rate and RPMs. Note: It is extremely important to circulate the debris and fill away from the hard bottom before starting to cut a core. The fill must be washed away if the junk is to be successfully fished. |

| 2 | Tag the bottom and watch the torque gauge. The rotary should slap as the shoe gets over the cones or junk, and then the torque should smooth out. Note: You should know the measurements from the bottom of the shoe to the top catcher and to where you would bump up. |

| 3 | Proceed to cut the core until the shoe quits or you bump up. |

| 4 | Mill on the shoe with 3,000 to 4,000 lbs. of weight. Caution: Do not exceed 4,000 lbs. or you will wear the shoe out prematurely. Note: If you cut a full core, you will get an increase in pump pressure. |

| 5 | To break the core, stop the rotary, slow the pump down, and raise the drill pipe an inch or two. |

| 6 | Rotate a few rounds and pick up a few more inches. |

| 7 | If there is no drag (torque and drag), THEN pull out of the hole without rotating to keep the junk in the basket. |

| 8 | If a good core is recovered but contains no junk, THEN normal drilling may be resumed because you have pushed the junk out of the way into the formation. |

Reverse Circulation Junk Basket

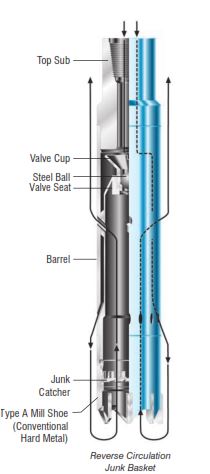

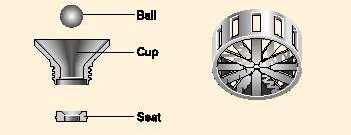

A reverse circulating basket uses the force of a vacuum created inside the tool to pull the junk up into the basket. Generally, By dropping a ball is inside the drill string, thereby initiating the reverse circulation process. Pumping mud through the jets produces a vacuum inside the barrel, sucking mud up into it. Replenishing the mud deficiency in the barrel by mud entering from below will carry any junk and the finger catchers will trap them. Because it is not necessary to cut a core to recover the junk when using the reverse flow basket, the main application for this type of basket is in hard formations.

Caution: Trying to cut and break off a core using this tool may result in breaking the fingers on the basket because the formation is too hard.

The fantastic design of this fishing tool of reverse circulation enhances junk retrieving and reduces mis-runs. Here, you can pull it wet due to the drain-through option that allows passage of fluids even if there are plugging in the inner barrel. Also, you can convert this tool easily to a fishing magnet and still keep the reverse circulation option.

They have other advantages such as:

- Firstly, Allows debris to pass one way

- Secondly, Using of normal circulation,

- Thirdly, When you are ready for fishing (fishing in drilling), drop a ball that will move a sleeve which will change the direction of the flow.

Running Procedure

| Step | Action |

| 1 | Run the reverse basket to within several feet of the bottom. |

| 2 | Start the mud pump slowly and increase the rate to the maximum safe circulating pressure. Circulate all of the fill before dropping the ball. |

| 3 | Tag the bottom and rotate to stir up the junk. Caution: Do not drop the ball to initiate reverse circulation until a thorough pumping job is done. |

| 4 | Drop the ball and pump it down at a moderate speed. It should fall at the rate of 1-1/2 minutes per thousand feet. Note: If a drill string has been dropped and all cones for tricone bit have been sheared off, it may be necessary to cut a core to recover them, because they may be embedded in the borehole. |

Collecting all of the junk

The only way you will know if you have collected all of the junk is to pull out the basket and examine the contents. If you suspect that junk remains in the hole, run the basket again and repeat the procedure.

If no junk comes back in the basket, you probably walled off the junk, shoving it into the formation. This is not a problem in soft formations and you can be satisfied that the junk is out of the way.

Boot Basket

If you can’t circulate heavy debris or junk, you of course will need this fishing tool. Because cuttings are flowing past the basket’s larger OD, smaller OD, and top connection, there will be a decrease in the velocity that will allow the basket to trap junk. So, you should install boot baskets as closely as possible to the mill, bit, or junk basket to get its full benefit.

Boot baskets can have any connection, but most have a regular thread that will make up directly to a bit or mill without the need for a crossover sub. Wash pipe boot baskets are made with a wash pipe connection on the bottom and are run in place of the drive sub when run with wash pipe or rotary shoes.

You can run boot baskets in tandem to increase capacity. Also, some operators will place another boot basket up the hole several joints. Therefore, they will be able to pick up junk that moved higher than the lower basket due to pumping.

You shouldn’t accept field welding on the mandrel of the boot basket. For example, if there is welding of gussets on the mandrel to reinforce the boot without stress relief, these welds may produce stress cracks. This can result in mandrel failure and an expensive fishing job.

Poor-Boy Junk Basket

The main application of poor boy baskets is when you have an irregular shape of fish or are too large for conventional junk baskets. They are custom-made for a single job and are most likely used only once. Poor boy baskets should be about ½” smaller than the ID of the hole.

Using mild steel in the construction of poor boy baskets will allow bending without breaking. Also, dressing them with finger-type bottoms will allow them to close around a fish or with tungsten carbide, wire, dimple rings, or rods.

When the poor boy basket goes over the junk, the fishing man pulls up on the string. The dimples or cuts in the ID of the tool create friction, engaging the junk.

Running technique is critical to success with this tool. It is necessary to rotate and circulate the tool down over the junk without applying excessive weight. Because of the slots between the teeth, the tool will usually run rough while the junk is at the level of the teeth. After making a hole (by measurement) and the junk moves up into the smooth bowl of the basket, the tool will begin to run smoothly. After accomplishing this step, apply weight while rotating the tool, and the fingers will bend in and “orange peel,” retaining the junk inside the bowl. There shall be a cut for new teeth for each job.

Friction-Socket

Often, an “off the shelf” or ready-made junk basket will not work because of the size and shape of the junk in the hole. In many cases, So there are other recommended alternative solutions. The following are some instances:

- Cutting inverted “U” shapes in a piece of pipe and bending them in until they practically touch can also make a friction catch. This tool can be pushed down over a long, tubular piece of junk and is quite effective in cases where the junk’s dimensions are unknown.

- If the ID of the catcher is not large enough to accommodate the junk, a shoe or length of pipe may be used as the body of a shop-made junk basket. A series of holes may be bored or burned around the circumference of the material and steel cables brazed into place to form a catcher. It is not possible to rotate this tool on the junk as the cables will be broken and torn out, but the tool can be pushed down over junk and the junk retained by the catcher.

These two examples can remedy the two most frequent problems:

- junk that is too large to catch or

- junk with an unknown outside diameter.

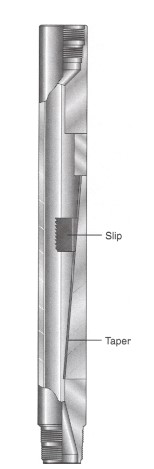

Several good “mouse trap” design tools have emerged in past years. For example, Kelo overshot or oversocket, has tracks set on opposite sides and at an angle from the bottom to the top of the bowl (Figure below). Various slips can be fitted to ride up and down on the beveled track. As the tool is lowered over the fish, the slip is pushed up

Other Designs in the market:

- SP Type B Boot Basket – BHG

- SP Washpipe Boot Basket – BHG

- Core-Type Junk Basket – SLB

- SP Globe-Type Junk Basket- BHG

- EP WELL-CLEAN Element-Style Boot Basket that aims to recover debris during drilling riser and BOP cleaning operations – BHG

- SP Internal Boot Basket – BHG

- Jet Junk Basket: to retrieve stubborn debris from the hole bottom – SLB

- Bowen Junk Sub: Just install above the bit or scrapper to catch the heavy objects.