The Releasing Spear Fishing Tools are used in drilling to internally engage and to retrieve all sizes of tubing, drill pipe, and casing as opposed to overshots that catch on the outside. It is designed to assure positive internal engagement with the fish and is ruggedly built to withstand severe jarring (Drilling Jars) and pulling strains without distorting the fish.

Usually, a spear is not the first choice, as the spear will have a smaller internal bore than an overshot which limits the running of some tools and instruments through it for cutting (Mechanical Cutter), free-pointing (FPI Tool), and in some cases, backing-off.

Spears, however, are popular for use in pulling casing liners, picking up parted or stuck casing (pipe sticking), or fishing any pipe that has become enlarged when parted due to explosive shots, fatigue, or splintering.

Releasing Spear Tool Mechanism In Fishing

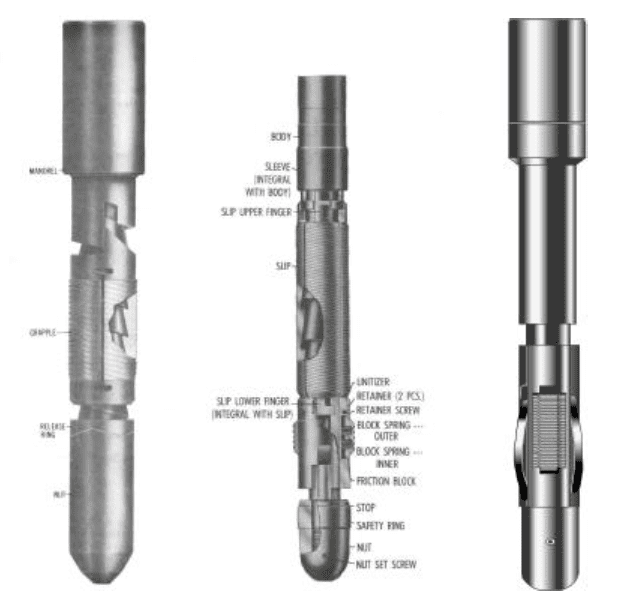

The most popular spears in use today are built on the same principles as overshots with a tapered helix on the mandrel and a matching surface on the inside of the grapple. The slip or gripping surface is on the outside surface of the spear so that it will catch and grip the inside of the pipe that is being fished. Due to the design with the small-bore in the mandrel, spears are usually very strong.

The spear is run inside the fish and positioned. The slips are released by the action of the J-slot by using left-hand torque, moving the drill string down a short distance, and then picking it back up slowly. This action releases the slips so they can slide up over a taper on the body of the spear as the spear is moved uphole. The slips move outward engaging the inner wall of the fish.

In order to release a spear, it is rotated to the right. If the grapple is frozen to the mandrel, it may be necessary to bump down to free or ‘shuck’ the grapple. Usually, a bumper sub is run just above the spear and this can be used to effectively jar down (Mechanical Jar – Hydraulic Jar) and free the grapple.

The spear is a very versatile tool, in that it can be run in the string above an internal cutting tool if desired or in combination with other tools. Milling tools (Milling In Drilling Operations Guidelines For Oil & Gas) may be run below the spear to open up the pipe so that the spear can enter and catch the fish.

Size

When running the spear, verify that the grapple is the correct size for the pipe to be caught. Refer to the Bowen instruction manual catching range table. For example, a grapple to catch 9.625″ by 47 to 58# casing will have a nominal catch range of 8.597″ with a minimum of 8.534″ and a maximum of 8.755″.

Drilling Assembly Of Spear Fishing Tools

It is essential that the spear is properly assembled. Be sure to check the gap of the spear grapple, which is marked on the tang. Tape the grapple in the catch position prior to running into the hole. You should always install a spear pack-off when you are performing fishing operations in an open hole. A packer assembly may be run on the bottom of the spear to pack off. A bumper jar is also required to aid in releasing the spear.

Types Of Spear Fishing Tool In Drilling

There are many types of releasing spears, but the most popular ones are:

- Bowen-Itco

- Bowen Full Circle

- Houston Engineers rotating and releasing spear.

Bowen Itco Releasing Spear Fishing Tools

Running the spear into the fish, causing the grapple to be pushed up, operates the Bowen Itco releasing spear. The grapple gets tighter as it goes into the fish. When the spear is picked up, the grapple is pulled down on the tapers of the spear. The harder the spear is pulled, the tighter the grapple will bite. Below is the running procedure for such type:

- Slowly lower the string until the spear has entered the fish to the desired depth or the stop sub.

- If the fish is not caught, rotate one full turn to the left to make sure that the grapple is still in the catch position. This turns the mandrel down through the grapple, putting the grapple in the catch position. A straight pull will then wedge the grapple into positive engagement with the fish.

- Bump down with the bumper jars and/or the weight of the fishing string to break the engagement.

- Rotate one round to the right at the tool. This moves the mandrel upward through the grapple, forcing the grapple down against the release ring and putting the spear in the release position.

- If the spear does not release, bump down again then simultaneously rotate to the right while elevating the string until the spear is clear of the fish.

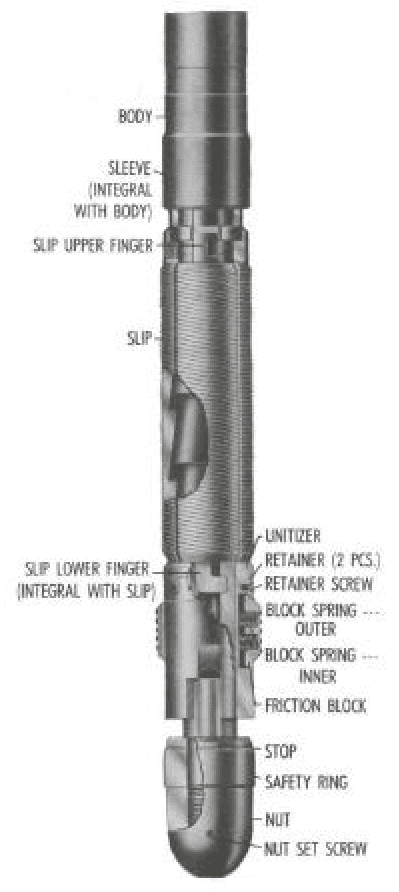

Bowen Full Circle Releasing Spear

The Bowen Full Circle Releasing Spear is a good tool to use for ensuring positive internal engagement over a long section of a fish. The design of the full circle slips and the effect of the tapers of the body on the slips cause the expansion strain to be distributed evenly over a long vertical section and virtually over the entire inner circumference of the fish. Below are the procedures for running the such tool:

- Lower the fishing string until the spear has entered the fish to the desired depth.

- Rotate the string at least 1/6 turn to the left and then pull on the fish by raising the fishing string.

- To release the fish, bump down and rotate 1/6 turn to the right and pick up.

Houston Engineers Spear

The Houston Engineers Releasing Spear consists of:

- slip

- mandrel

- grapple

- bull nose nut

- releasing ring.

All of the components of the Houston Engineers Releasing Spear are locked together and cannot unscrew in the hole. However, even after high torque loads in either direction, this spear can be disassembled by hand for field maintenance. Full bore is maintained in all sizes to facilitate the use of wireline equipment. Only one part, the slip, is exposed to extreme wear. Below are the procedures for running the such tool:

- Run the spear in the hole in the catch position. IF you do not engage the fish, THEN rotate the spear one round to the left to reset the tool in the catch position.

- Pull up to set the slip in the fish. Note: If torque is required, pull 30,000 to 40,000 pounds to set the slip securely, then slack off to 3,000 pounds over pull. Torque can then be applied in either direction.

Best Practice For Releasing Fishing Spears

A typical spear assembly when fishing 9 5/8” casing would be: 9 5/8” Spear c/w Cup and Stop Ring, 8” Bumper Sub, 8” Fishing Jar, 6 x 8” Drill Collars, 8” Fishing Accelerator, 2 x 8” Drill Collars, 15 HWDP.

When fishing casing and other thin-walled tubulars then an internal catch spear and grapple is the tool to be used. The spear is made up of an inner mandrel which is cut on a tapered helix. The grapple then screws onto the mandrel and will move up and down the helix as the string is rotated.

Two types of grapple are available. The one-piece grapple is sized to catch small to medium-sized tubing and casing whereas the segment type grapple is designed for larger bore casing and conductor. Grapples are supplied for a nominal size of casing or tubing and will be stamped with the weight range they can catch. Right-hand rotation will move the grapple to the bottom of the mandrel which is the release position. Conversely left hand rotation will move the grapple to the top of the mandrel which is the catch position.

An elastomer cup is normally run on the mandrel to allow for circulating through the fish. Above the mandrel, a fishing spear stop or ring tool is positioned to provide a “NoGo” on the top of the casing.

The best practice to use when running a spear is:

- The spear and grapple will be sized for the particular casing being run.

- Ensure the equipment sizing is confirmed as part of the casing checks.

- Paint the stop ring to confirm full entry into the fish.

- Make up the spear and photograph the assembly for later reference.

- Screw the grapple up the mandrel and into the catch position.

- Secure the grapple in the catch position using the lock pin (if fitted) or divers

tape. - RIH slowly, check the pop-off setting will cover a plugged string.

- Make a good pipe count and double-check the BHA and Pipe Tally.

- Break circulation one stand above the fish and condition the mud.

- Establish the drags with the pump on and off but do not rotate.

- Wash down looking for resistance or an increase in pressure.

- Do not run the drilling Kelly below the rotary when using a fishing spear tool.

- Work down inside the fish until resistance is seen.

- Watch for the pressure rise if the casing or hole is packed-off.

- Set down half the BHA weight to check engagement.

- Pick and confirm the fish is latched.

- Do not “drop and catch” the fish as this is not good practice.

- If the spear is not latched, work down torque and turn the mandrel one turn

to the left then try again. - Circulate, jar up and overpull as required to free the fish.

- Circulate clean, then POOH slowly so as to prevent swabbing.

- While POOH, do not rotate or move the string down into the slips.

- To come off the fish inhole, simply turn the string to the right.

- When back on the surface, release the spear in the same way.