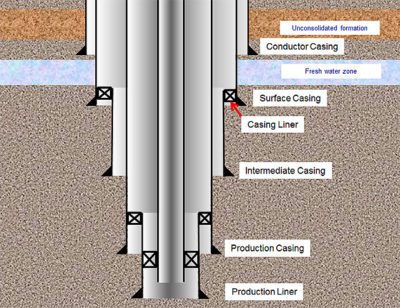

In General, there are six casing types used in drilling Casing Design in all onshore and offshore wells, which are as follows:

- Structural Casing or Drive Pipe

- Conductor Casing

- Surface Casing

- Intermediate or Protective Casing

- Production Casing

- Casing liner

Types Of Casing Used In Drilling Wells

Structural Casing or Drive Pipe

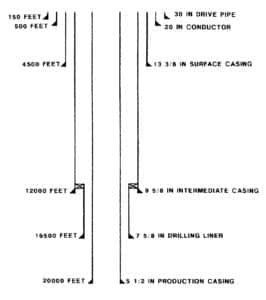

This casing string provides initial hole support close to the surface and generally varies in length from about 30 to 300 feet. The casing may be driven or hole drilled. The casing may be cemented if it is necessary to drill a hole. Figure 1 represents a casing design for a deep, offshore well.

Conductor Casing

This string of casing in some areas may be the first casing string set and cemented. In others, particularly offshore rigs, it is the first string of casing that provides any protection against formation pore pressures.

The general practice is to cement around this string of casing back to the surface. If cement returns are not obtained at the surface, a so-called top job is typical, where cement is displaced into the annulus from the surface through a small string of pipe. We can summarize its purposes as follows:

- To Prevent erosion around the rig’s foundation where the surface sand is weak.

- To make the cellar more stable.

- To provide a good start for subsequent drilling

- To circulate drilling fluids through to the surface.

- To protect inner casings from corrosion.

The conductor casing type setting depth is usually based on the amount required to prevent washout of the shallow borehole when drilling to the depth of the surface casing and to support the weight of the surface casing.

A drilling diverter can be installed on the conductor to divert flow in case of a shallow kick. Usually, when the surface sand is stable, this casing string is unnecessary.

See also: Running procedures for 30″ conductor Pipes.

Surface Casing

This type of casing, which is used in drilling wells, serves several purposes:

- To protect shallow freshwater sands from possible contamination

- To prevent cave-in of unconsolidated, weaker, near-surface sediments and in the event of a kick.

- To allow the flow to be contained by the blowout preventers.

- Any subsequent casing strings run in the well to support and protect from corrosion.

See also: Casing Running and Cementing Preparation, Casing Running – installation patterns, Casing Running Procedures.

Intermediate Casing Type In Drilling

This string of casing, which is used on oil and gas wells, serves several purposes:

- Intermediate casing is similar to surface casing in that it permits the final depth objective to be reached safely.

- To isolate problem zones, i.e., abnormal pressure, lost circulation, sloughing, or caving zones between the surface and production casing depths.

More than one intermediate string can be set if necessary.

Liner Type Of Casing In Drilling

A liner can be used for drilling to isolate problem zones, production, or both.

A liner is a different type of casing profile in that it does not extend from the bottom of the drilled well to the surface but is suspended from the bottom of the next largest casing string. Usually, it only extends a few hundred feet above the last casing shoe depth.

One of the primary advantages of using liners is the savings in steel costs. Also, liners may be run quickly, compared to full casing strings, which improves the chances of getting the liner to the desired depth.

A disadvantage of a liner is that the previous casing string must withstand the pressures encountered after drilling below the liner. This means a heavier design with a larger diameter casing. The casing above the liner is also subject to drill string wear for extended periods.

Protective and production drilling casing liner types are set, and their purpose is the same as an entire casing string. Another problem with liners has been getting a good cement seal around the liner.

When running and cementing, liners are generally neither moved nor centralized ( Learn more about casing centralization). As a result, it is not easy to get cement on all sides of the liner. Liner hangers are available that permit liner movement during cementing; however, they are not commonly used. Other liner problems include standard clearances, which are sometimes small, particularly with deep production liners.

Production Casing

This string of casing is set and cemented to isolate the productive formations. The amount of cement used is generally related to company preference and would be based on the volume needed to bring the cement back to a pre-determined height.

The volume of cement may be based on caliper log calculations or a given amount of excess based on experience. It should be remembered that cement will travel more readily up the large side of the hole. As a result, it may be necessary to use more excess than cement calculations indicate to cover the casing adequately in the small part of the hole if it needs to be centralized.