Formation losses usually account for most of the additional costs when actual drilling fluid costs exceed estimated figures, which is why so much effort goes into preventing down-hole losses in the first place. If offset data is available, we can design the well to isolate lost-circulation zones behind casing pipe before drilling deeper formations requiring higher mud densities. However, this is not always possible. A range of Lost Circulation Material (LCM) treatments are available to prevent or cure formation losses in drilling oil & gas wells, which we will discuss later.

We recommend visiting the following links for a complete understanding of the loss of circulation problem:

- Causes Of Lost Circulation Problem

- How To Cure Lost Circulation Problem,

- Precautions To be considered to avoid Mud loss problems

Main Types Of Lost Circulation Material

In General, These are the most common Lost Circulation materials in drilling oil and gas wells:

- Fiber

- Granular

- Flakes

Fiber Lost Circulation Material

The fiber LCM type used in oil and gas wells is long, slender, and flexible. It also comes in many sizes and lengths of fiber. Adding fibrous LCM to the drilling fluid will help reduce losses & maintain circulation if there is a lost circulation into fractures or highly permeable zones.

Examples

- Cedar fiber (wood fiber).

- Sawdust (wood fiber).

- Drilling paper (paper).

- Magma Fiber (mineral fiber).

- Shredded cane stalk.

- Hair.

Granular Lost Circulation Material

This lost circulation material is chunky and prepared in various particle sizes. Adding granular LCM to drilling fluid in oil & gas wells will assist in delaying the loss of mud into fractures or highly permeable formations.

Actually, granular Lost Circulation Material should be insoluble and inert to any drilling mud system in which it is utilized.

Examples

- Nutshells – (fine, medium & coarse)

- cotton hulls

- (coarse graphite).

- Calcium carbonate (fine, medium & coarse).

- corncobs

- Formica

- Wood

Flake

The Flake type of lost-circulation material (LCM) is thin and flat, with a large surface area. Flake LCM had various sizes. It should be insoluble and inert to the mud system in which it is used. It aims to shut off any mud loss zones in a well and help stop lost circulation.

Examples

- Flake (cellophane).

- Pieces of plastic (cellophane)

- Mica (fine and coarse).

A lot of laboratory studies were run to explain how LCM works when used in oil and gas wells, how to evaluate the performance, and how to improve the lost circulation material sealing ability in drilling operations (Scott and Lummus 1955; Abrams 1977; Nayberg 1986; Dick et al. 2000; Hettema et al. 2007; Kageson-Loe et al. 2009; Kefi et al. 2010; Clapper et al. 2011; Alsaba et al. 2014b, c, 2016).

Detecting Loss Zones For Better LCM Treatment

LCM treatments may be ineffective because we are not spotting it across the thief zone where formation losses occur. If this is the case, and if the loss rate is significant, then run the following logging tools to locate the thief zone:

Temperature Log

Mud flowing into the formation will cool the area where losses occur, which can be detected by running a temperature log inside the drill pipe.

Spinner Log

This propeller device measures flow in the wellbore, enabling significant formation losses to be detected if the drill pipe is out of the hole.

Noise Log

This uses a very sensitive microphone (hydrophone) to detect noise created by turbulent flow in the region where fluid passes into the formation.

Decision To Use LCM In Drilling Oil & Gas

Surface Losses

Before deciding to use Lost circulation Materials (LCM) in drilling oil & gas wells, check the surface system to make sure that active fluid is not being lost at the surface due to surface leaks or other factors (e.g., whole mud losses caused by blinded Shaker screens or shale-shaker power failure).

ECD

Formation losses may not occur when the circulating rate is reduced or stopped. Still, the Equivalent Circulating Density (ECD) will increase while circulating or drilling, which may result in losses. Therefore, circulation rates and ROPs should be controlled when formation losses occur to reduce the ECD and help minimize losses.

Try Other Ways To Reduce Formation Losses Other Than Lost Circulation Material

There are simple ways you could think of one of them before you decide to use lost circulation material as follows:

- Firstly, think about reducing the circulating rate and/or ROP, as this will reduce down-hole ECDs by reducing friction in the hole and reducing cuttings loading in the annulus.

- Secondly, try to reduce the drilling fluid rheology without affecting hole cleaning efficiency,

- Thirdly, why not reduce the drilling fluid density without destabilizing the hole or inducing a kick?

- But, If formation losses are severe and cannot be controlled, it may be necessary to suspend drilling or drill “blind” while circulating with reduced or no returns before setting an intermediary casing string to isolate the thief zone.

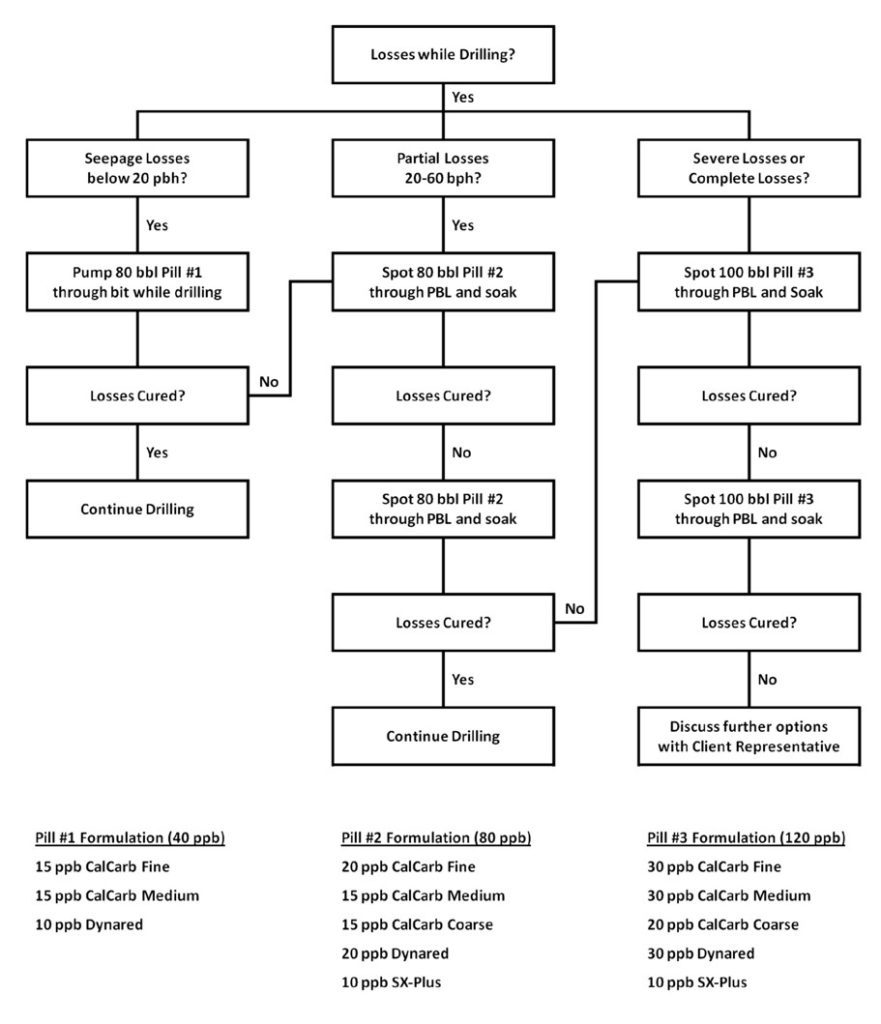

Lost Circulation Decision Tree

A typical lost circulation decision tree appears overleaf. Decision trees are generally developed for each field and each well interval based on offset well data, so there is no guarantee that they will be effective if used in other fields. Below is an example of a lost circulation decision tree for one of the drilling mud companies.

Lost Circulation Material Treatment Selection

In general, several cheap Lost circulation Materials are available for treating lost circulation, including Nut Plug, Mica, Sawdust, Wood Chips, Fibers, Calcium Carbonate, Marble Chips, and more expensive specialist products.

The choice of treatments for lost circulation will depend on the following factors:

- Formation being drilled

- Hole size

- Loss rate.

- Precious treatment results from offset wells

If you are designing mud program for an exploratory well, keep the density as low as possible to minimize losses.

Simple Tips While LCM Pill Preparation

We usually prepare LCM pills using mud from the active circulating system. However, this will produce a higher-density pill after mixing all the LCM products. In addition, this might increase the hydrostatic pressure of the fluid and the loss rate to the formation when pumped downhole.

Check the LCM pill density before pumping the downhole to ensure it is the same as the active circulating mud density. LCM pills should not be lighter because this could destabilize the wellbore, bring the oil or gas well under balance, and create a well-control situation.

We should not bypass the shale shakers or fit it with coarser shaker screens when treating the circulating system with Lost Circulation Material because this will increase the drilled solids in the mud, which might increase density and rheology. If this happens, the circulating ECDs will increase and encourage more mud losses to the formation.

Limitations

- Take Care when using coarser grades of Lost Circulation Material while drilling because there are often limitations on LCM concentrations and particle sizes that can be pumped through the MWD and LWD tools.

- Remember that Coarse Drilling LCM may cause plugging of the bit jets, especially if the LCM has been mixed quickly and is still lumpy as it is pumped down-hole.

- Don’t use Conventional LCM materials (e.g., Nut Plug, Mica, etc.) when trying to cure losses in the production zone because this might damage the formation.

Losses in the reservoir should be treated using Lost circulation material which is designed for use in production zones as sized Calcium Carbonate bridging material, which can be acidized.

Final Words

Firstly, The LCM For Seepage Losses Recommendation:

- Treat the active circulating system with five ppb to 10 ppb fine-grade lost circulation material, such as Nut Plug, Mica, or Calcium Carbonate.

- Regular dosing with LCM at the mixing hopper to maintain concentration and compensate for Lost Circulation Material screened at the drilling shale shakers.

- Don’t bypass the shale shaker if LCM blinds its screens because drilled solids will then build up & will increase the drilling fluid density and rheology, potentially having more losses.

- Sweep the hole periodically with fine and medium grade Quick Seal and Mica or fine and medium grade Calcium Carbonate bridging particles if in the production zone.

Secondly, The LCM For Partial Losses Recommendation:

- Firstly, Spot a viscous pill comprising 30 ppb to 40 ppb fine and medium grade LCM (Nut Plug, Mica, and K.Seal) across the suspected loss zone.

- Pull the drill string up into the casing shoe to minimize the potential for differential pipe sticking while leaving the LCM pill to soak in the loss zone for a few hours.

- Keep the annulus full with mud to maintain fluid hydrostatic throughout this period before running back to the bottom and gradually increasing the circulating rate while monitoring for losses.

- Repeat or adjust the LCM concentration if the first attempt is unsuccessful.

Thirdly, The LCM For Complete Losses Recommendation:

- Firstly, spot one or more pills comprising 100 ppb or more fine, medium, and coarse-grade LCM across the loss zone.

- Secondly, apply pressure to squeeze the LCM pill into the loss zone.

- Take care when using coarser grades of LCM to avoid any risk of plugging the down-hole tools.

- At last, remember to formulate LCM pills in the production zone with sized Calcium Carbonate bridging particles to minimize formation damage.