A drill collar is an essential tool used in oil and gas rigs for drilling operations. It has many functions, including providing weight on the drilling bit for efficient drilling and stability during operation. Understanding the importance of drill collars and how they work is vital for successful drilling operations. In this article, we will explore the significance of drill collars and their role in the drilling process.

Definition of Drill Collars

A Drill Collar (DC) is a heavy, thick-walled steel tube with threaded connections cut (NB not welded) on both ends that we use in oilfield drilling rigs. They are designed to withstand downhole conditions while under compression and tension. While designing BHA, drilling engineers place DCs below the drill pipes or the heavy drill pipes above the Drill Bit as DCs are the predominant component of the Drilling BHA. To select the proper DC, you must have all the information about Drill collar Weights, Size, Specs, Definition, lengths, and types.

Manufacturing Process

In addition, they are manufactured from chrome-molybdenum alloy 4140 (4140 is a code that indicates the chemical makeup of the metal). Furthermore, they are heat-treated and quenched over their entire length, with a Brinell hardness range of 255 to 341 to obtain mechanical properties as specified by API Spec 7-1. Their bore is accurately machined to ensure smooth, balanced rotation. Collars are manufactured in a wide range of sizes (ODs) and are available in length ranges 2: 9.15 – 9.76 m (30 – 32 ft); and 3: 12.8 – 13.27 m (42 ft-43 ft).

DC can also be manufactured using magnetic steel or spiral collar, including complex threaded connections, weight increases, and spiral grooves on the outside surface for better drilling mud type flow control.

Drill Collars Function

Some of the functions of the collars are as follows:

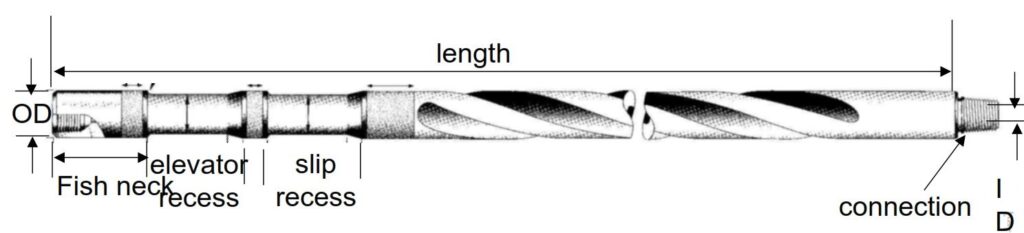

Drill Collar Specifications

Drill collars are available in many sizes and shapes, such as round, square, triangular, and spiral grooved.

The parameters used for identifying drill collar specifications are:

- OD: 9 1/2″, 8″, 6″, 4 3/4″ etc.,

- ID: 3 1/2″, 3″, 2 1/2″”, 2 3/8″ etc.,

- Length: Usually range II

- Material: Steel, Monel

- Connection: 6 5/8″ REG etc.

Drilling Collar Types

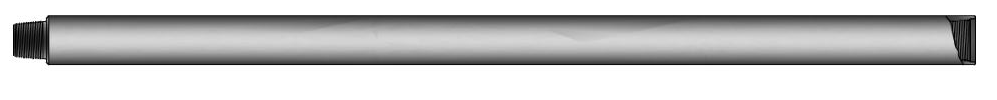

Slick Type

The slick type is the most common one that has been used since the beginning. It has no features. Its major function is to add weight to the bit and increase the stability while drilling.

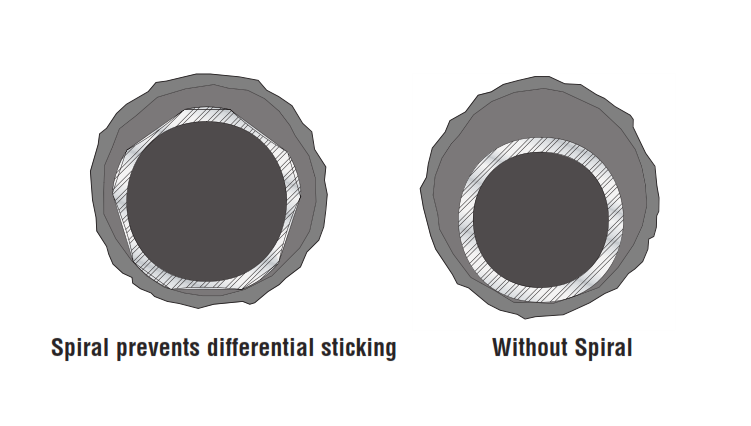

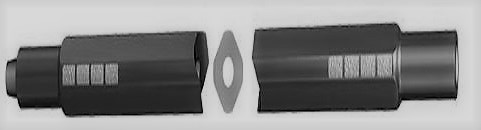

Anti-wall Stick / Spiral Drill Collar

We commonly use this type. They have spiral flats, or shallow depressions, that are machined in their surface along the more significant part of their lengths. This reduces their effective weight per unit length by approximately 4%. Reducing the wall contact area between the DC and the hole wall dramatically reduces the possibility of differential wall sticking.

Square Type

These are drill collars with a square section and a diagonal dimension 1.6 mm (1/16″) less than the drill bit size, with hard-facing material applied to the corners. We generally run this type in the string when drilling crooked hole formations. The reason is to provide maximum stabilization and prevent deviation from the existing course of the hole. The square type use is, however, not commonplace.

Non-Magnetic Type

The most common type of DC is the non-magnetic drill collar. It is made from alloy steel with an outer surface machined to a specific smoothness and an elevator recess radius that meets dimensional requirements. We should pay special care when making up NMDCs. This is because the material is more susceptible to the galling of the threads and shoulders than normal DCs. They aim to isolate directional Survey Instruments from magnetic distortion due to the steel Drill String.

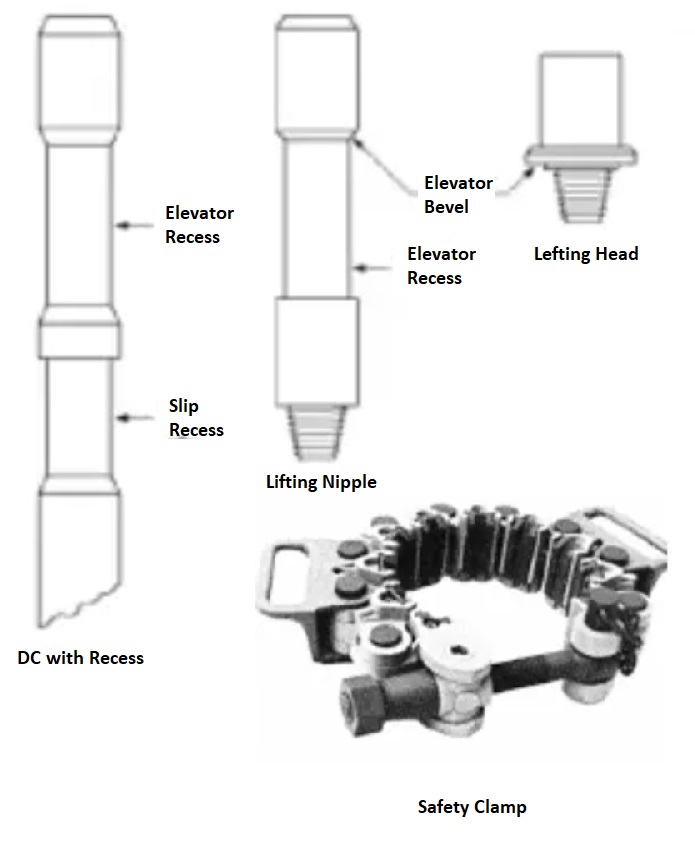

Lifting & Making Up Facilities For Drill Collars

DCs should have Elevator recesses (Figure 8) for lifting and suspending them by slip and rig elevator. When handling flush collars, we should use a lifting nipple or lifting head (using the same torque as an ordinary DC connection). The threads and shoulders of the lifting nipples should be treated and inspected with the same care as the drill collar threads. In addition, to prevent a DC from slipping through the drilling slips, we install a safety clamp around the drill collar above the slips. This clamp comprises links with spring-loaded inserts/dies with tapered backs (see Figure 9).