We can define oil based mud as a drilling fluid with oil as its continuous external phase, and the water, if present, is a dispersed or internal phase. The solids in an oil-based fluid are oil-wet, all drilling additives are oil dispersible, and their filtrate is oil. The water, if present, is emulsified in the oil phase. Since the 1930s, oil and gas companies have recognized that they can achieve better productivity from reservoirs when using oil-based mud rather than Water-based mud to drill through the reservoir.

This is large because the oil does not cause the clays in the reservoir to swell or cause changes in the wettability of the formations. Crude oil was first used to drill through the pay zone but suffered several disadvantages (low mud gel strength, limited viscosity, safety hazard due to low flash point). (Check also: the testing procedures of OBM)

Oil-Based Drilling Mud Classifications & Types

Oil-based fluids have two basic classifications: inverted emulsions and all-oil muds. The amount of water present will describe the type of oil-based drilling fluid. The oil used in these types of oil-based fluids can range from crude oil, refined oils such as diesel or mineral oils, or the non-petroleum organic fluids that are currently available. Now, we consider the latter type of fluids (invert fluids, pseudo-oils, non-aqueous fluids, and synthetic fluids) more environmentally acceptable than diesel or mineral oils.

As a completion fluid (during perforating and workovers), there are three types of oil-based muds in common use:

- Full oil (water content < 5%)

- Invert oil emulsions (water content 5 – 50%)

- Synthetic or Pseudo oil based mud

Conventional Oil Based Drilling Fluid

Conventional all-oil muds have oil as the external phase but are designed to be water-free when formulated or used. The first, called “oil mud,” has 95-100% of its liquid phase oil, with 0-5% unintentional water. This water is usually unintentionally incorporated into the system through numerous sources, most notably from the drilled formations. Since water is not usually present, there is a requirement for asphaltic-type materials and clays to control fluid loss and viscosity. Since we try to avoid adding this water to the system during the formulation, there is only a minimum requirement for emulsifiers while drilling.

All-oil mud can withstand small quantities of water; however, if the water becomes a contaminant, we should convert the mud to an inverted emulsion. If the water is not quickly emulsified, the solids in the mud can become water-wet and cause stability problems. Water-wet solids will blind the shaker screens, and the whole mud may get lost.

Invert Emulsion Mud

The second type of oil-based drilling fluid is the “inverted emulsion” mud. As the name implies, an invert is an emulsion mud utilizing oil as the continuous or external phase. Brine constitutes the discontinuous or internal phase of the mud. Typical oil/brine ratios range from 95/5 to 50/50 in inverted emulsion systems.

Invert emulsions are oil muds formulated to contain moderate to high water concentrations. Water is an integral part of the inverted emulsion and usually contains a salt such as calcium or sodium chloride. We add special emulsifiers to tightly emulsify the water as the internal phase and prevent the water from breaking out and coalescing into more extensive water droplets.

If not tightly emulsified, these water droplets can water-wet the already oil-wet solids and affect emulsion stability. Therefore, we use particular lignite derivatives or asphaltites as fluid loss control agents and bentonite derivatives to increase the viscosity and suspension properties of the system. Invert emulsions are usually tightly emulsified, low fluid loss oil muds. A lot have seen an improvement in drilling rates when they relaxed the fluid loss control of the system. Thus, the name “relaxed” inverted emulsion OBM. Also, the relaxed inverted emulsion fluids do not use as much emulsifier as the regular inverted emulsion systems.

Synthetic or Pseudo oil based mud

The base fluids in synthetic muds are non-petroleum organic compounds that act like petroleum-derived oils in drilling operations but appear to biodegrade readily in the ocean. Like most OBMs, synthetic muds are inverted emulsions, with the synthetic fluid as the external or continuous phase and brine as the internal phase. Many mud companies introduced several base drilling fluids in the marketplace during the last few years, mainly in the size range C 16 -C 24.

In the field, many thought synthetic drilling fluids performed as well as conventional OBM’s. Some differences in their properties remain, however, which may be desirable attributes (+) or which may pose some limitations on handling and use (-):

- Synthetic fluids are severalfold more expensive than oils used in conventional OBM’s;

- Synthetic muds appear to be more biodegradable and disperse in seawater more readily;

- Synthetic muds are considerably more viscous at ambient temperatures, but they also thin

- more readily with increasing temperature;

- Synthetic muds are not as thermally stable;

- Synthetic muds do not hydrate or dehydrate shales as rapidly;

Why Oil-Based Mud

Oil muds offer many advantages over water-based muds. The high initial cost of the OBM can be a factor in not selecting this type of mud system. However, if we consider the overall drilling costs (check also drilling cost per foot), the costs accompanying the use of OBM are usually less than those for WBM. We shall describe some of its applications below.

Shale Stability

OBMs are most suited for drilling water-sensitive shales. Formulated with the proper salinity, oil-based drilling fluids can prevent water movement from the mud into the shale. In some cases, we can draw water from the shale, which could result in strengthening. However, it is also possible, but very uncommon, to draw too much water from the shale (with too high a salinity) and cause a shale to be less stable. It is desirable to have enough salinity to prevent water migration into the shale but not to allow dehydration of the shale. This is the “balanced activity” concept. Usually, we determine the required salinity through field experience. Shale cores that the oil mud has not altered are necessary to determine the salinity requirements accurately.

Penetration Rates

OBM formulations can drill faster than WBM and still provide excellent shale stability. Relaxed filtrate invert emulsions usually have a high oil-to-water content, and some additives are omitted to control fluid loss. These systems do not use the primary emulsifiers that can reduce the drilling rate and do not have the same temperature stability as conventional invert OBM. The relaxed type is especially suitable for drilling with PDC drill bits.

High Temperatures

Oil muds have the ability to drill formations where bottom hole temperatures exceed water-based mud tolerances, especially in the presence of contaminants. We use OBM at temperatures approaching 550°F. This is because its formulation can withstand high temperatures over long periods, unlike WBMs, which can break down and lead to viscosity loss, fluid loss control, and corrosion.

Drilling Salts

Generally, inverted mud provides gauge holes and does not leach out salt. Adding salt to the water phase will prevent the salt from dissolving into the emulsified water phase. Even up to saturation and over-saturation, water-based mud does not assure that there will be no leaching out for the salts.

Coring Fluids

Special OBM provides a suitable coring fluid for minimum water saturation changes. Oil-based coring fluids frequently give low invasion. These fluids are usually water-free and thus require only a minimal content of emulsifiers. The emulsifiers are powerful oil-wetting agents and can cause oil-wetting of the formation. Oil-based coring fluids will not introduce any water into the core, so the determination of water saturation can be more accurate. The invading filtrate would not alter residual water saturation if we used low surfactant concentrations.

Packer Fluids

We consider the design of OBM packer fluids to be stable over long periods and when exposed to high temperatures. They provide long-term stable packer fluids under conditions of high temperature since the additives are extremely temperature stable. Since oil is the continuous phase, corrosion is almost negligible compared to WBM under the same conditions. Properly formulated, packer fluids can suspend weighting material over long periods.

Oil-Based Drilling Mud Lubricity

The high lubricity oil muds offer makes them especially suited for highly deviated and horizontal wells. Along with the higher lubricity, the risk of differential sticking is minimized when using OBM. It has a thin filter cake, and the friction between the pipe and the wellbore is minimized, thus reducing the risk of differential sticking.

Low Pore Pressure Formations

The ability to drill low pore pressure formations is easily accomplished with oil muds since the mud weight can be maintained at a weight less than that of water. Mud weights as low as 7.5 lb/gal can be achieved. Also, oil-based muds provide better filter cakes.

Oil-Based Drilling Mud For Corrosion Control

Corrosion of the pipe is controlled since oil is the external phase and coats the pipe. Such muds offer exceptional corrosion protection due to the non-conductive nature of the oil, and corrosion cells cannot develop since the metal surfaces are oil-wet. The products used in drilling OBM are very thermally stable and do not degrade to produce corrosive products. Also, bacteria do not thrive in OBM.

Re-Use

Oil-based drilling muds have a high level of reusability as they are long-lasting and suppress bacterial growth. The mud can be stored for extended periods of time and then reused by mechanically removing drill solids.

Disadvantages Of Oil Based Drilling Mud

- The initial cost of oil mud is high, especially formulations based on mineral or synthetic fluids. The high cost can be offset by drilling OBM buy-back or leasing from the mud service company.

- Due to their high gas solubility, OBMs reduce kick detection compared to WBM. Such muds are costly when lost circulation occurs.

- When utilizing these muds, it is crucial to prioritize environmental concerns related to cuttings discharge, whole mud loss, and disposal. To avoid allergic reactions and irritations, it is recommended to take necessary precautions and refrain from skin contact as emulsifiers, brine, and lime can cause such reactions. Inhalation of fumes from oil muds can be irritating. Drilling OBM can damage the circulating system’s rubber parts and preclude particular oil-resistant rubber use.

- Oil muds pose potential fire hazards due to low flash points of vapors coming off the oil mud. Mineral and synthetic fluids have higher flash points than diesel and crude oils. Crude oils should be “weathered” before use in OBM.

- Additional rig equipment and modifications are necessary to minimize the loss of OBM.

- Electric logging must be modified for use. Oil muds are non-conductive; therefore, resistively measuring logs will not work (SP, resistivity, dipmeters).

- OBMs require emulsifiers that are potent oil-wetting materials, which can also change the wettability of the rock to an oil-wet condition, which provides resistance to oil flow. They are also more compressible than water muds; therefore, the downhole density may vary considerably from that measured at the surface.

Oil-Based Drilling Mud Products & Additives

| FUNCTION | M-I | Baker-Hughes | Baroid Drilling Fluid | Dowell | Anchor |

| PRIMARYEMULSIFIER | VERSA MUL | CARBO TEC L | INVERMUL | EMUL | ANCO-MUL PE |

| SECONDARYEMULSIFIER | VERSA COAT | CARBO MUL | EZ MUL | FL | ANCO-MUL SE |

| ORGANOLIGNIT | VERSA LIG | CARBOTROL A9 | DURATONE | NA | ANCO-MUL FR-L |

| ASPHALTIC FLC-GILSONITE | VERSA TROL | CARBO TROL | BARABLOK | TRUDRILL S | ANCO-MUL FR-G |

| ORGANOPHILIC BENTONITE | VG-69 | CARBO VIS | GELTONE II | TRUVIS | ANCO-MUL GEL-B |

| ORGANOPHILIC HECTORITE | ———— | CARBO GEL | BENTONE 38 | TRUVISHT | ANCO-MUL GEL-H |

| WETTING AGENT | VERSA WET | SURF COTE | DRILTREAT | O.W. | ANCO-MUL OWA |

| RHEOLOGICAL MODIFIER | VERSA MOD | SIX-UP | RM 63 | INTERDRILL | LOWRM |

| POLYMERIC VISCOSIFIER | VERSA HRP | CARBO VISHT | X-VIS | TRUPLEX | ANCO-MUL GEL-P |

| OIL MUD THINNER | VERSA THIN | SURF COTE | OMC | DEFLOC | ANCO-MUL |

Oil muds require unique products to ensure that the emulsion is exceptionally stable and can with-

stand conditions of high temperature and contaminants. Oil mud products must be dispersible in

the external oil phase. In our article oil-based mud additives, you will find more info about the following:

- Primary Emulsifier

- Secondary emulsifiers

- Organophilic lignites

- Organophilic gellants

- Wetting agents

- Polymeric viscosifiers

- Rheological modifiers

- Weighting Agents

Water in Oil Emulsions

The original inverts contained the same essential ingredients as the actual oil muds. The concentrations of materials differed, however. Small concentrations of calcium and magnesium soaps were added to asphalt, with sodium chloride brine used as the internal phase. The earliest of these systems, No-Blok (Magcobar) and Kenex (Ken Corp., later IMC), had no other additives. Although they were more flexible (rheologically) than the actual mud, they were less stable. In recent years, the base oil in drilling OBMs has been replaced by synthetic fluids such as esters and ethers. These muds are generally called synthetic or pseudo-drilling OBM.

Mechanism

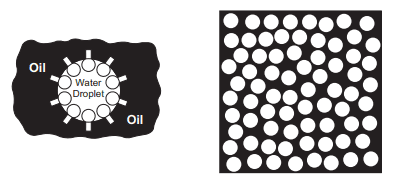

The water in inverted emulsion fluids is dispersed as tiny droplets throughout the oil. Emulsifiers coat the droplets, preventing them from coalescing and making the mud unstable (i.e., larger water droplets will settle and break down the emulsion). A calcium or magnesium fatty acid soap is often used as an emulsifier in an oil-based mud. The long hydrocarbon chain of the soap molecule tends to be soluble in oil, while the ionic portion tends to be soluble in water. When soap is added to a mixture of oil and water, the molecule takes up the position shown in Figure 1.

This reduces the surface energy of the interface and keeps the water droplets in the emulsion. Other emulsifiers (e.g., naphthenic acid and tree sap soaps) can also be used. The effectiveness of an emulsifier depends on the alkalinity and electrolytes present in the water phase and also on the temperature of the mud. The water droplets should be as tiny and uniform as possible to increase stability. This is done by shearing the mud by agitators. When oil is added, the stability increases since the distance between droplets becomes greater. This causes a decrease in viscosity. For good mud properties, there must be a balance between oil and water. The water droplets help to:

- Support the barite

- Reduce filter loss

- Build viscosity and gel strength

Wettability Control

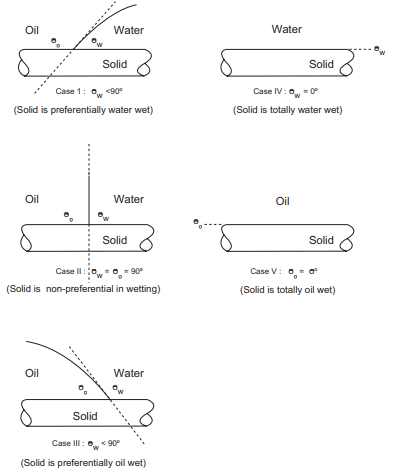

When a drop of liquid is placed on a solid, it will either:

- Spread itself over the surface of the solid.

- Remain as a stable drop.

The shape of the drop depends on the adhesive forces between the molecules of the solid and liquid phases. The wettability of a given solid surface to a given liquid is defined by the contact angle q (Figure 2).

When two liquids are present and brought into contact with a solid, one will preferentially wet the solid. Most natural minerals are water-wet. When water-wet solids enter an emulsion, the solids tend to agglomerate with the water and settle out. To overcome this problem, surfactants are added to the oil phase to change the solids from water-wet to oil-wet. The soaps added as emulsifiers will also act as wettability control agents, but special surfactants are more effective.

The stability of the emulsion can be tested by measuring the conductivity of the mud. The stronger the emulsion, the higher the voltage required for an electric current to flow.

A loose emulsion is often due to water-wet solids or free water. When water-wet solids are present, the surface of the mud becomes less shiny, and the cuttings tend to stick to each other and blind the shale shaker. Barite added for density control must also be oil-wet; otherwise, the particles will tend to settle out.

Balanced activity

The activity of a substance is its affinity or potential for water. All rocks which contain clay will absorb water to some extent. This is because there is a difference between the activity of the shales and the activity of the mud. If the chemical potentials of the shale and the mud were equal, the shale would not absorb any water. This would eliminate any swelling of the clays, leading to borehole instability. For balanced activity in an oil-based mud, the activity of the mud (Aw) must be adjusted to equal the activity of the drilled formation. CaCl2 or NaCl may be added to the mud to keep Aw above 0.75. The activity of the shale can be measured by taking samples from the shaker.

Viscosity control

Excessive viscosity in an oil-based drilling fluid may be the result of the following:

- Firstly, too much water content – When properly emulsified, it behaves like a solid. As the water fraction increases, so does the viscosity.

- Secondly, drilled solids – The solids content affects viscosity in oil-based mud similarly to Water Based Mud. The build-up of fine solids (e.g., due to the diamond Drilling Bit) may produce high PV, YP, and gel strengths. Therefore, we should use finer shale shaker screens (120 mesh) to reduce this effect. Water-wet solids may also cause problems with high YP.

Many recommend performing pilot tests to assess the implications of adding drilling chemicals to the mud to control viscosity. In addition, we may add emulsifiers and wetting agents to reduce viscosity.

We may add water and special viscosifiers (organically treated bentonite) to increase viscosity.

Filtration control

Only the oil phase in oil-based drilling fluids is free to form a filtrate, making an oil-based mud suitable for formations we must not damage. The fluid loss is generally minimal with drilling OBMs (less than 3cc at 500 psi and 300 degrees F). During the test, the filtrate should never have water (indicating a poor emulsion). Ideally, If water is present, we should add more emulsifying agents. In addition, we can cure excessive filtrate volumes by adding polymers, lignite, etc. (pilot tests are essential).

Conclusion

Modern oil-based fluids use low-toxicity base oils and various chemical additives to build good properties. The use of oil in the drilling mud does have several disadvantages:

- Higher initial cost

- More stringent pollution controls required

- Reduced effectiveness of some logging tools (resistivity logs)

- Detection of Kicks is more difficult due to gas solubility in a base oil.

However, for some applications, oil-based muds are very cost-effective. These include:

- To drill and core pay zones

- To drill troublesome formations (e.g., shale, salt)

- To add lubricity in directional drilling (preventing Stuck Pipe)

- To reduce corrosion

In brief, there are two types of OBM. An oil mud has less than 5% water. An inverted emulsion has a water concentration greater than 5%. Generally, we use the drilling OBMs for specific purposes, such as maintaining hole stability in hydratable formations or drilling hydrogen sulfide-bearing zones. While drilling hydratable formations, we must maintain the salinity level of an oil-based fluid at levels greater than the salinity of the formation. Also, we can control mud contamination from hydrogen sulfide or carbon dioxide gas with excess lime in the system.

The High Cost Of OBM Preparation

The initial preparation of many oil muds was time-consuming and expensive because additives such as asphalt did not blend readily in crude or diesel oils but required heat for adequate dispersion. Therefore, we had to prepare mud containing these additives at a mixing plant and haul it to the drilling rig site. Make-up costs were also high with true oil mud due to the higher volume percentage of oil plus the large additions of asphalt. Water contamination was an acute problem causing excessive viscosity and water wetting of solids, necessitating replacement of the system or at least dilution with new mud.

Adjusting Oil-Based Muds Properties

Water contamination of inverted emulsions required adjusting mud properties by adding oil and emulsifiers. The principal components in the drilling OBM could not be added to adjust a single property without affecting most of the other mud properties. Single additives to adjust or control specific mud properties were unavailable at the time to provide the flexibility and versatility needed for a lower cost.

References & Related Papers

- Katende, A., Boyou, N. V., Ismail, I., Chung, D. Z., Sagala, F., Hussein, N., & Ismail, M. S. (2019). Improving OBM and WBM performance in a high-temperature hole using nano-silica nanoparticles. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 577, 645-673.

- J. M. Davison; M. Jones; C. E. Shuchart; C. Gerard SPE Drill & Compl 16 (02): 127–134. Paper Number: SPE-72063-PA