If the well is not circulated well and the hole is not cleaned from cuttings properly, they will gather & settle around the Drill String, usually the Bottom Hole Assembly BHA, due to the small clearance between the Bottom Hole Assembly BHA and the hole, which will lead to a stuck probably in the Drill Collar and this pipe stuck will be mainly from inadequate hole cleaning. Here, we shall discuss hole cleaning, especially in deviated and horizontal wells.

Indications

- While POOH with any type of BHA, the Drilling Stabilizers and the Drilling Bit scrapes the cuttings.

- The cuttings get accumulated around the Drilling Bit and Stabilizers, as seen in the below Figure.

- With continuing POOH, Pick-up weight increases as more cutting accumulates around the Bottom Hole Assembly BHA.

- When enough drilling cutting accumulated around the Bottom Hole Assembly BHA, the pulling force will not be able to move Drill String upward.

Annular Velocity Effect In Hole Cleaning

Annular velocity is the speed of a fluid’s movement in an annulus column in wells drilled with circulating drilling fluid. It is commonly measured in feet per minute (ft/min) or meters per minute (m/min). Annular velocity is often abbreviated as AV, though this is not exclusively so, as AV also refers to apparent viscosity calculated from rheometer readings from tests that the mud engineer performs.

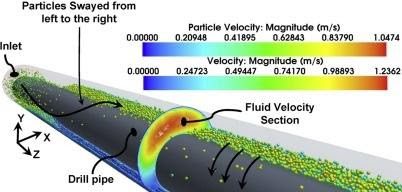

The annular velocity of the drilling fluid depends mainly on pumps output and the clearance it goes through.

We must agree that the factor of annular velocity is important as it is the factor that helps in transferring the cutting to the surface. The well will have a good hole cleaning if the annular velocity is higher enough to push the cuttings upward. Furthermore, the annulus will not be loaded with cuttings. And as the annular velocity in between the hole and the Drill String is lower, the possibility of the pipe sticking increases. In other words, the stuck pipe possibility increases in the over-gauge sections.

An increase in flow rate will result in more efficient cuttings removal under all conditions. However, how high a flow rate can be increased may be limited by:

- The maximum allowed Drilling ECD.

- The susceptibility of the open hole section to hydraulic erosion.

- The availability of rig hydraulic power.

Why Is Hole Inclination Angle Important For Hole Cleaning In Drilling Deviated & Horizontal Wells?

Field experience has proven that, as hole inclination increases from zero to approximately 67°, hole cleaning becomes more difficult, and a higher flow rate is more favorable. The flow rate requirements reach a maximum at +/- 65 to 67°, and then slightly reduced toward the horizontal.

Also, it has been proven that at a hole inclination range of 25° to 45°, a stop in circulation due to a sudden pump shutdown or any other reason can result in the sloughing of cuttings downward to the bottom, which may cause mechanical pipe stuck problems.

The Effect Of Drill String Rotation On Hole Cleaning

Field experience has shown that Drill String rotation is important in improving hole cleaning. How much the rotation affects the hole cleaning depends on other factors:

- Flow rate.

- Pipe rotation.

- String dynamic behavior.

- Cuttings size.

- Mud Rheology.

Drill String rotation is one of the major contributors to better hole cleaning. It can be noticed when it is decided to use a drilling Downhole Mud Motor and the well is Directional Drilled with sliding mode, it is preferred to pump a lot of Hi-Vis pills, and if you don’t do that, you will notice increasing on ECD, drag and torque.

The Mud Motor issue was solved with the new Rotary Steerable Systems. But still, rotation of the Drill String can result in cyclic stresses, which will accelerate pipe fatigue and casing wear. In slim hole drilling, high Drill String RPM can increase ECDs because of the high annular friction pressure losses.

Also, the pipe whirling action will affect the hole cleaning as it increases the annular velocity on the low side, which will mechanically agitate the cuttings when the pipe moves to the high side of the hole.

Hole/Pipe Eccentricity

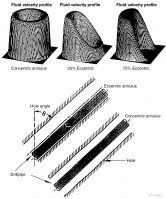

In the inclined section of the hole, gravity forces the pipe to rest on the low side. This creates a narrow gap in the annulus below the pipe, decreasing fluid velocity. Therefore, the mud will not efficiently transport drilling cuttings to the surface.

As eccentricity increases, fluid velocities decrease in the narrow gap, which is dramatically noticed for high-viscosity fluid. However, because the selected well trajectory governs eccentricity, its adverse impact on hole cleaning may be unavoidable.

The Relationship Between Penetration Rate And Hole Cleaning

As Penetration Rate (ROP) increases, the drilling cutting amount in annulus will increase. So to have adequate hole cleaning while drilling with a high Penetration Rate (ROP), it will be required to adjust the flow rate and/or pipe rotation. If there is no ability to increase such parameters due to hole problems, it should be a good practice to decrease the Penetration Rate (ROP).

Off-course, a decrease in ROP will affect the drilling costs (also check oil well drilling well cost per foot). Still, at the same time, the value of avoiding other drilling problems, such as mechanical stuck or higher Torque And Drag, is much greater than the loss in Penetration Rate (ROP).

Why Mud Viscosity And Not Mud Density

There are two main factors related to drilling fluid that affects hole cleaning: viscosity and density. The main density functions are providing borehole stability and the prevention of formation-fluid intrusion into the borehole. Any unnecessary increase in mud density will hurt the Penetration Rate (ROP) and, under the given in-situ stresses, may cause formation fracturing. So mud density should not be used to improve the hole cleaning. The viscosity function, on the other hand, will suspend any cuttings produced from the wellbore. Sometimes Hi-Vis pills are required for better hole cleaning.

The Fact About The Effect Of Cuttings Characteristics On Hole Cleaning

The size, distribution, shape, and specific gravity of cuttings affect their dynamic behavior in the drilling mud. Most rock’s specific gravity is approximately 2.6, so cutting specific gravity can’t be considered a factor affecting cuttings transport. Drilling Bits Types affect the cutting’s sizes and shapes, the regrinding after they are generated, and the breakage by their own bombardment and with the Drill String rotating action.

So it is more difficult to control cutting characteristics, even if a certain Bit Type has been chosen to generate them. Smaller cuttings are more difficult to transport in Directional Drilling; however, with increasing mud viscosity and higher rotating action, fine particles will be suspended and transported to the surface.

How to Recognize The Hole Cleaning Problems By Simple Warning Signs

- Insufficient amounts of drilling cuttings on shale shaker.

- Overpull increases dramatically at connection times and while trips (check also tripping pipe procedures).

- Overpull gets reduced when circulating.

- Increase in pump pressure and pressure spikes when the hole momentarily plugs up.

- Pump pressure is much higher than predicted using the hydraulics program.

How to Identify The Stuck Occured By Inadequate Hole Cleaning

- Stuck shortly after pumps are shut off.

- Circulation lost.

Preventive Action To Avoid Stuck

- Keep the pumps running. It might be impossible to take the survey at the moment.

- If the motor is used, rotate before tripping out of the hole.

- Check shale shakers to see if the cuttings are being removed.

- The ROP can be lowered to reduce the amount of cuttings.

- Circulate all cuttings out before tripping out.

References:

- Drillers Stuck Pipe Drilling Handbook