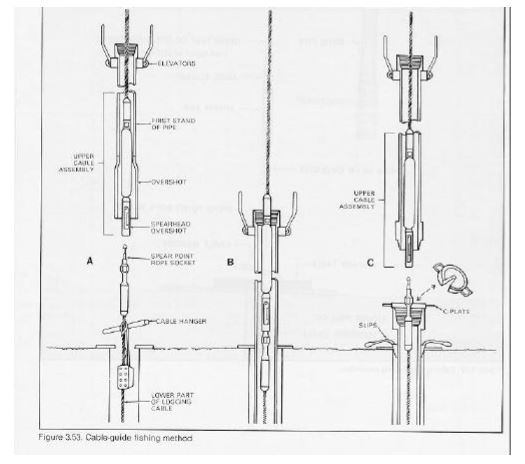

The cable guide method or “cut and Thread” method is one technique for fishing stuck wireline (Check also: Sticking Pipe) and/or logging tools. Even though it is dangerous and time-consuming, the cable guide method is preferred over the side door overshot method as it is the surest method.

This method is used for retrieving wireline stuck in the oil and gas wells. In cut and thread operations, We grip the wireline securely with a special tool and cut it at the rig floor. Then we fix the cut end in a stand of drill pipe. As the Top Drive holds the pipe, the wireline is threaded through another stand of drill pipe, which is screwed onto the stand in the wellbore. We continue with this process until the stuck wireline is retrieved.

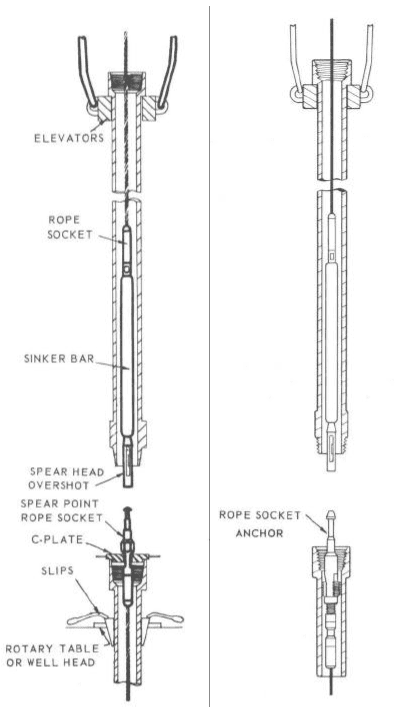

Rope Socket Assembly

The rope socket assembly used in the cut and thread fishing technique (Figure 2) consists of:

- T bar cable hanger

- Fishing spear head rope socket with hexagon adapter

- “C” plate

- spear head overshot

- knuckle joint

- singer bar

- rope socket.

Precautions

Urge everyone to be alert throughout this tiresome of this fishing operation to prevent costly mistakes and/or serious accidents. Some of the primary hazards (oil rig hazards) are:

- the cable may be dropped

- a broken strand of wire may ball up ahead of the overshot

- the impact of the tool on a bridge may cut the cable

- the cable may double back around the overshot as it is removed from a Drilling key seat.

To avoid these hazards, it is a good idea to conduct a safety meeting with all personnel involved to explain how the procedure is supposed to work.

Cut and Thread Fishing Technique Procedures

Cutting The Cable

- Slide a C plate over the rotary. Note: The C plate is utilized for safety reasons. It stops such tools from falling into the well.

- Take an overpull (margin of overpull) on the cable of 2,000 lbs. above the line weight.

- Attach the T-bar clamp to the wireline. Note: Ensure that the slip liners are the correct size to fit the cable.

- Employ a torque wrench to tighten the T-bar with the appropriate torque.

- Function-test the T-bar to check for slippage. Tape or mark the line at the T-bar and bounce the T-bar on the rotary. If the tape moves at all, the T-bar is not sufficiently tight.

- Tape the line in the place where you will cut it. This helps to ensure a clean cut and prohibits fraying the end of the line.

- Employ a wireline cutter to cut the cable, leaving an 8- foot tail.

- Secure the part of the cable that is attached to the truck so that it will not run over the crown and hurt someone.

Preparing The Rig For Cut And Thread Fishing Technique

- Lower the block that supports the upper sheave so that the sheaves may be rearranged in the drilling rig derrick. The top sheave should be hung as high as possible in the derrick and just to the left of the monkey board. The lower sheave must be moved back from the rotary to be out of the way of the operations on the rig floor. Note: This is an essential step as the block must be used to handle the drill pipe.

- Attach a rope socket, adapter, and spear point to the well end of the cable. Note: The slips and slip carrier shall be selected according to the cable size. Remember you should always consider only new slips each time you perform this operation.

- Attach the rope socket to the truck end of the cable with 10 feet of weight bars, a knuckle/swivel joint between them, and a rope socket overshot. Note: To weight the wireline and make it fall into the stand of drill pipe, one or two standard sinker or weight bars are typically utilized. The knuckle joint allows flexibility so that the derrick man can stab the wireline tools into the stand of drill pipe.

- Tighten the parts securely with a 24″ pipe wrench.

Performing A Test Pull For Cut And Thread Fishing Technique

- Latch the rope socket overshot to the spear point. Note: The T-bar clamp is still attached to the cable at this point.

- Take a 5,000-pound strain on the cable.

- After one minute, check for any movement by checking the tape marks.

- If there has been no movement, slack off on the T-bar and disconnect the rope socket overshot.

Dressing The Overshot

- Dress the Bowen 150 fishing overshot with the correct grapple to catch the fishing neck. Note: Utilize a Nitraloy grapple if available. A plain grapple control is sufficient as we have not circulation through the fish.

- Attach the restricted ID sub onto the overshot followed by a mud saver sub, which will screw onto the drill pipe.

- Make up all tools by hand.

- Thread the rope socket spear point through the overshot and replace the adapter with the hexagon-shaped adapter. Note: The hexagon adapter will not pass through the restricted sub if it is dropped.

Attaching The Drill Pipe

- Latch the first stand of pipe and have the derrick man stab the wireline tools into it.

- Lower the wireline tools down through the stand of drill pipe.

- Latch the rope socket overshot onto the spear point and take the slack out of the line.

- Instruct the crew to make the fishing overshot up onto the stand of drill pipe by hand.

- Pick up on the wireline and remove the T-bar clamp.

- Set the drilling slips on the fishing tools and tighten the connections.

- Tighten the guide by hand with a pipe wrench and sledgehammer.

Running In The Hole

- Instruct the winch operator to adjust the tension to normal plus at least 2,000 pounds of overpull and slowly go in the hole. Note: It is important for the winch operator to watch the weight indicator in the truck for any change and to maintain 2,000 pounds of over pull on the line at all times.

- When the first stand has been run in, place the C-plate in the slot between the rope socket and the hexagonal adapter. Caution: Keep your hands in a safe place; do not get your fingers caught under the C-plate.

- Instruct the winch operator to slack off the cable until it is supported by the C-plate. The C-plate rests on top of the drill pipe tool joint for which it is sized.

- Instruct the winch operator to mark the cable with tape so that he will return to the same spot for each stand of drill pipe run.

- Release the rope socket overshot with special tongs.

- After the driller has latched another stand of pipe, instruct the winch operator to pull the wireline tools up for the derrick man to stab them into the drill pipe.

- Drop the rope socket overshot down through the pipe to be attached to the spear.

- After the overshot is latched, instruct the winch operator to pick up on the cable, maintaining a 2,000 pound over pull.

- Make up the second stand and proceed in the hole at a rate of two minutes per stand, not including make up time. Note: Going in the hole slowly is the only safe way. This is because if you go in fast, you might hit a bridge with the overshot and cut the cable in two down hole.

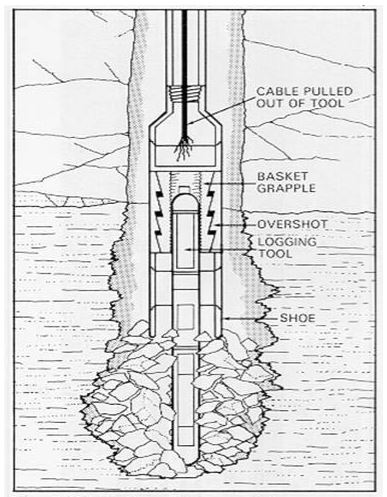

Correcting Problems While Running In

You can predict a problem with the cable-based on how quickly the cable tension increases while running in. The following table shows the problems you can expect according to the degree of cable tension increase and how you should correct the problem.

| IF the cable tension increases… | Then … | And you should … |

| Sharply | the cable may be stuck in a key seat and doubled back outside the overshot | increase the cable tension with the winch and the guide should free the cable ahead of the overshot. |

| Gradually | the elevation of the cable head spear will lower, potentially below the top of the pipe as you advance into the well | add a short length of sucker rod between the rope socket and the spear to prevent pulling too much tension on the line. |

If a bridge is encountered, it should be cleaned by circulating the mud. Circulation may clear up the problem unless the cable was cut by the initial impact.

To avoid problems, ensure that at least 2,000 pounds of overpull is maintained on the cable at all times.

Freeing The Line

If the line has been stuck and is then freed, the winch operator will know immediately as he will lose the 2,000 pounds of over pull on his weight indicator. To prove that the line has been freed, pull the logging tool up several feet. If there is no weight increase on the wireline weight indicator as the line is pulled up, you know that the line and logging tools are free.

Note: The driller may reciprocate the pipe while circulating. This will help prevent the string from becoming stuck if the pipe is at rest.

- With the spearhead hanging on the C-plate, thread the circulating sub over the rope socket overshot and hold it there by hand.

- Latch the overshot into the spearhead, lift the cable, and remove the C-plate.

- Thread the circulating sub into the drill pipe.

- Place a circulating baffle around the wireline and drop it into the circulating sub.

- Lower the cable until the rope socket rests on top of the baffle.

- Release the overshot.

- Screw the oil and gas Kelly into the circulating sub.

Confirming Overshot Engagement In Cut And Thread Fishing Technique

After the Kelly is set back and the rope socket overshot has been reconnected, spool up the wireline until the logging tool is pulled into the overshot. Note: Before this step, the cable must be cut, getting rid of the rope socket overshot.

If the cable tension decreases when picking up on the drill pipe and the logging tool is inside the fishing overshot, this confirms that the logging tool is in the overshot. Review this procedure for proof of engagement with the customer. When the customer agrees, pull off at the weak point using the procedure on the following page.

Parting The Cable At The Weak Point

Install the cable clamp and let the cable rest on top of the drill pipe tool joint that is in the rotary.

- Cut the cable and remove the rope sockets.

- Tie both ends of the cable together in a square knot.

- Pull up on the cable until the square knot is tight.

- Tape the loose ends and remove the cable clamp.

- Spool the cable onto the truck, pulling the knot carefully over the top sheave until the knot is just before the measuring device.

- Clamp off the cable.

- Slack off the cable and remove the cable from the measuring device.

- Take up the slack in the cable and remove the cable clamp.

- Spool the knot onto the drum.

- Clamp the cable.

- Slack off the cable and reinstall the cable onto the measuring device.

- Take up the slack and remove the cable clamp.

- Continue spooling the cable onto the drum until the logging tool is pulled up securely into the overshot. Note: When the cable is being removed, the driller should work the pipe to prevent sticking the drill string.

- Install the cable clamp at the top of the drill pipe.

- Latch the elevators around the cable under the clamp and slowly pull until the cable is pulled in two at the weak point.

- Spool the cable up on the drum.

Securing The Fish In Cut And Thread Fishing Technique

- Install the Kelly and blow the disk out of the pump out sub. Note: All the disks in the table are made of bronze that is 0.010 inches thick.

- Pull the pipe and fish out of the hole without rotating.

- Set the slips on the fish and secure it with a C-type safety clamp.

- Release the overshot from the fish and turn the rest over to the logging company personnel.