Oilfield Magnetic fishing tools consist of permanent or electric magnets running on a conductor line. The outer edge of permanent magnets has circulating ports, which wash away fill and cuttings and make contact with the fish. A brass sleeve is fitted between the magnetic core and the outer body to avoid any drag on the pipe or casing pipe and to contain the magnetic field.

Permanent magnets have the advantage of the circulation washing away any fill so that the junk is exposed. Ordinarily, one can detect when contact is made with 18 of 29 fish by rotation. The operator should then thoroughly circulate the hole, shut the mud pump off, and retrieve the fish without rotation.

Before going in-depth, we suggest for you the articles below:

Application

During drilling operations, tool failures, milling jobs, and accidents can result in various objects like drilling bit cones, bearings, slips, mill cuttings, tong pins, and hammers falling to the bottom of the hole. Retrieving such objects can be difficult, but we can use magnetic attraction to engage and retrieve them. The magnetic fishing tools are an essential accessory for all diamond coring operations. Chipped bit teeth and broken bearings can damage or reduce the performance of a diamond core bit (PDC Drill Bits).

Generally, these fishing magnets can help by completely cleaning the hole of all such particles in a single run, thereby ensuring the safety and performance of the bit (Roller Cone Bit Performance – PDC Bit Performance).

Types

Fishing magnets are either permanent magnets fitted into a body with circulating ports or electromagnets run on a conductor line. There are also inline magnets or downhole magnets. Magnets will only pick up ferrous metal. Other methods should be used to recover brass, aluminum, carbide, and stainless steel.

Permanent Magnets

Permanent magnets have circulating ports around the outer edge so we can wash away the fill and cuttings and contact the fish. Typically, there is a brass sleeve between the magnetic core and the outer body to contain the magnetic field and avoid any drag on the pipe or casing. Permanent magnets facilitate the circulation of fluid to wash away debris and expose obstructions. The operator can usually detect when catching fish by rotating the equipment. The operator should then thoroughly circulate the hole, shut the pump off, and retrieve the fish. Pulling the workstring should not be rotated because there is a chance of slinging the fish off.

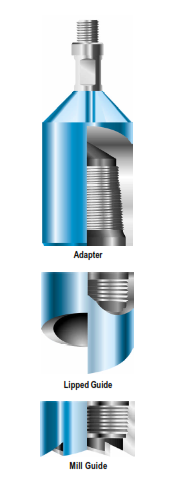

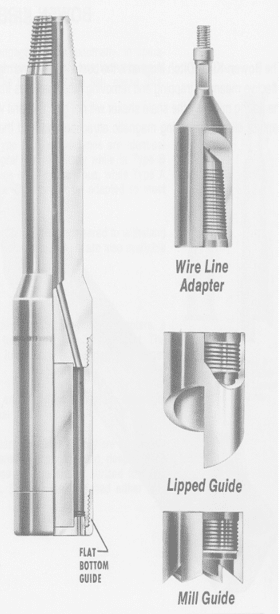

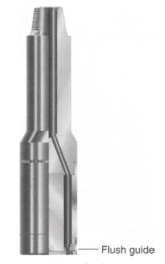

In Figure 11-1, you can see that permanent magnets usually have a cut-lip guide, a mill-tooth guide (which is the most popular one), or a flush guide (resembling a thread protector). The mill or cut-lip guide that extends below the magnet is extremely helpful in retaining the fish and preventing the drag off inside the casing.

Downhole or Inline Magnetic Fishing Tool

Downhole or inline magnets (Figure 11-2) are added to a bottom-hole assembly to help remove ferrous-metal debris. They have a box-by-pin connection and resemble a drill pipe pup joint. Very strong magnets attract metal chips from the wellbore fluid between the connections. The downhole oilfield fishing magnet can also clean metal cuttings and other ferrous-metal debris from casing collars, horizontal wellbores, and sub-sea blowout preventer (BOP) stacks. The inline magnets assist with cutting- and milling-debris removal in situations with either low annular velocity or well fluids with poor carrying capacity. To avoid putting too much weight on the magnet, it’s best to run the downhole or inline magnet higher up in the string when using it for milling or drilling. On the other hand, if we used the magnets to recover perforating gun debris, we should run them below the perforating guns.

Electromagnets

Electromagnets are run on a conductor line and are charged only when the bottom of the well is reached. They have the advantage of quick trips in and out of the hole, plus the added lifting power of an electromagnet. However, it cannot be reached if the fish is covered with fill or debris because there is no way to circulate this tool down.

Operations

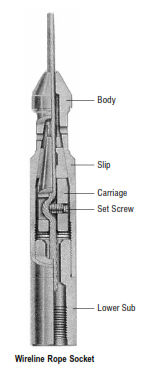

The Operation typically operates on tubing or drill pipe, but they can also work on wire lines if necessary. To operate on a wireline, you need to use Sucker Rod Adaptors and Wire-line Rope Sockets, which are available. The general procedure is as follows:

- Once you assemble the Magnet on the running string,

- Lower it to a position within 6 inches or 1 foot of the fish.

- Then, circulate the fluid long enough to remove heavy cuttings.

- After that, reduce the circulation and lower the Magnet until it contacts the fish.

- Rotate it enough to ensure good contact and then discontinue circulation.

- In Bowen magnetic fishing tools, we can use the Flush Guide to catch big objects like sledgehammers and flat items that won’t fit in other guides. If you need to retrieve a few cones or prepare for diamond coring, the Mill Guide is your go-to.

- But if you lose three or more cones, the Lipped Guide is your best bet. It’ll dig one out of the nest and roll it over another to push it up to the Pole Plate.

- Don’t forget to swap in the Mill Guide for the second run.

The Lipped Guide also works wonders on long objects that are lying sideways. For instance, if you lose an 18-inch pipe wrench in the hole, it’ll probably lean to one side. No worries, use the Lipped Guide to straighten it up. But be careful not to put too much weight on it, or it’ll damage the Magnet Pole Plate. To get rid of the fish, bring the Magnet up to the surface and make sure all the circulation holes are clear. If there’s any debris, remove it with a small rod probe or screwdriver. Repeat for any other objects in the hole.

Baker Hughes Magnetic Fishing Tools In The Oilfield

The Baker Hughes X-Treme Clean XP downhole magnet is a tool designed for use in deepwater, deep, and deviated wells. The tool effectively removes ferrous metal debris from the wellbore fluid, such as debris from window cutting, well packer milling, or junk milling, using powerful magnets that collect and bring it to the surface. You can use the downhole magnet alone or with blowout preventer jet subs, VACS™ tools, circulation subs, scrapers, brushes, and multi-task wellbore filters to clean thoroughly wellbore holes and displace.

Looking for an oilfield fishing magnet that can handle the toughest conditions? Look no further than BH’s one-piece mandrel design! With no internal connections to worry about, you can count on higher tensile and torque ratings than those of the tool joint. And thanks to BH high-temperature, high-strength magnets and unique magnet arrangement, you’ll enjoy exceptional metal debris-capturing and carrying capability that surpasses that of a conventional tool. Even in a high-pressure/high-temperature (HP/HT) well, the BH downhole magnet is up to the task!

The design of the downhole fishing tools allows metal debris to collect tightly in the space between the magnetic bars while still allowing adequate circulation between the tool’s outside diameter and the casing’s inside diameter. The robust replaceable magnet bars can withstand harsh downhole environments and allow easy assembly, replacement, and tool cleaning. Stabilizers at both ends of the tool centralize the tool and allow for more effective circulation in deviated wells. The downhole magnet also provides large inside diameter and annulus flow areas, allowing for more effective circulation and displacement operations. By allowing the drill pipe to rotate up to 150 rpm, cleaning efficiency can be significantly increased, making it suitable for drilling or milling applications where high rotational speed is required.

Features

The tool has several features and benefits. Firstly, it comes with high-strength rare earth magnets and a unique magnet arrangement that provides superior metal debris collecting capability in oilfield fishing. Secondly, the one-piece mandrel design has higher-than-tool-joint tensile and torque ratings, which makes it a reliable and effective tool for cleaning wellbores. This significantly mitigates completion and production risks and costs. Thirdly, it has the highest allowable rotation speed of 150 rpm, which increases cleaning efficiency. Fourthly, non-rotating stabilizers clean the well without damaging or wearing the casing wall. Fifthly, it has large circulation areas that improve circulation and displacement efficiency. Lastly, it has no exposed fasteners that could vibrate loose, which improves operational reliability.

MAGNOSHOE – Schlumberger Design

Introducing the MAGNOSHOE* tool – the latest addition to the M-I SWACO line of magnetic specialized fishing tools. The state-of-the-art magnet technology in this incredible oilfield tool simplifies well completions and enhances displacements. It actively picks up large ferrous debris that settles at the bottom of the wellbore, which cannot be circulated back into the path of a conventional drillstring magnet.

No matter the situation – whether large metallic debris has fallen to the bottom or low side of the wellbore or on top of another element higher up in the well – the MAGNOSHOE magnetic fishing tool is the perfect solution. Dealing with larger debris during drilling and wellbore preparation can be a major challenge. The MAGNOSHOE tool quickly captures and retains any target debris in the fluid stream until retrieving it on the surface. This tool makes activities like displacement or dedicated cleanout much easier, allowing easy removal and proceeding with the next operation.

But that’s not all – the MAGNOSHOE tool comes shipped in a protective shroud that shields the environment from the powerful magnetic field. It’s fully compliant for passenger or cargo aircraft shipping and has even passed an independent compass deflection test following IATA Packing Instruction 953. This protective shroud and safe shipping designation not only facilitate safe transport to the rig but also protect personnel from injury while handling the tool on the rig floor. Once connected to the end of the workstring with the shroud in place, the shroud is removed just before the tool is lowered through the rotary table. Experience the MAGNOSHOE tool and see why it’s the ultimate solution for drilling and wellbore preparation activities.

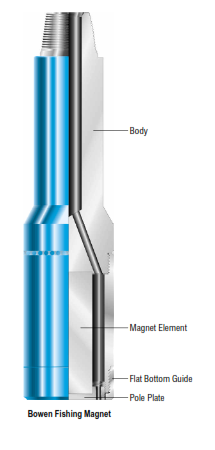

Magnetic Fishing Tools From Bowen

Oilfield Bowen Fishing Magnets are excellent tools for special-purpose fishing. Bowen Fishing Magnets use magnetic attraction to retrieve undrillable objects. They easily attract and retrieve small, odd-shaped items that other conventional fishing tools cannot catch using inside or outside catch mechanisms.

You can find these magnets in various sizes ranging from 1 to 20 inches in outer diameter, with all popular threaded pin connections suitable for wireline or pipe operation. Depending on their size, they can exert pulls from 5 pounds to 3,000 pounds. Most magnets allow full circulation during service, making them highly efficient and productive for any fishing operation. Optionally, the charger is available as an accessory.

The Bowen Oilfield Fishing Magnet’s patented construction boasts a special permanent magnet that creates a controlled magnetic field around its bottom pole plate. This plate, highly magnetic and extending across the bottom end of the tool, stays clean thanks to the circulation holes. The tool’s outside case, free of magnetism, makes it ideal for use inside cased holes. Crafted from alloy steel, the body features a tool joint pin at the top and a thread at the bottom to engage the housing. Ample circulation ports ensure efficient functioning. The manufacturers carefully engineer and furnish the magnetic element, using the most efficient permanent magnet available on the market to perform its crucial function precisely.

During assembly, the Housing, Body, and Pole Plate are screwed together and welded with the Magnetic Element in place. You can remove the Bottom Guide to facilitate replacing or repairing the Guide. After the assembly, NOV magnetizes the Magnet assembly and gives it a final inspection. Optional guides available are the Lipped Guide and Mill Guide.