Rotary Steerable System RSS represents an evolutionary step forward in directional drilling technology, overcoming the drawbacks of steerable motors and conventional rotary BHA types. In steerable motors, to initiate a change in the wellbore trajectory, halt the rotation in such a position that the bend in the motor points toward the new trajectory. This mode, known as the sliding mode, typically creates higher frictional forces on the drill string.

In extreme extended-reach drilling, the frictional force builds to the point where no axial weight is available to overcome the drill string drag against the wellbore; thus, further drilling is impossible. To overcome this limitation of the steerable motor assemblies, Rotary Steerable System was developed in the early 1990s, responding to the need for extended-reach drilling. The first RSS was used in BP’s Wytch Farm (UK) extended-reach wells.

Rotary Steerable System Advantages

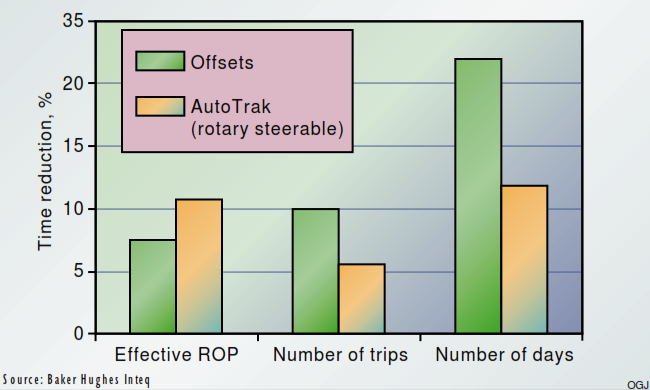

RSS allows continuous rotation of the drill string while steering the drilling bit. Thus, they generally have a better ROP than conventional steerable motor assemblies. Other benefits include better hole cleaning, lower torque and drag, and better hole quality. RSS is more complex mechanically and electronically and, therefore, more expensive than conventional steerable motor systems. This economic penalty tends to limit their use to highly demanding extended-reach wells or to the very complex profiles associated with “designer” wells.

- Continuous rotation while steering means less friction between the wellbore and the pipe, resulting in better weight transfer to the bit. This, in turn, gives higher penetration rates both directly and by allowing the use of more aggressive bits. It also facilitates the drilling of extended-reach wells.

- Compared with rotated bent housings, these RSS drilling systems produce smoother, “in-gauge”, non-spiraled borehole, which further reduces friction and results in an easier casing, wireline, and completion operations, as well as simpler tripping operations.

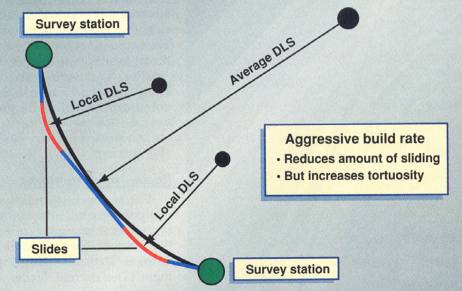

- Constant steering over the full drilling cycle instead of short periods of sliding results in a less tortuous well profile and again reduces friction, with the same benefits accruing.

- Constantly rotating pipe means improved cuttings removal, reducing the need for wiper trips and the chances of pipe stuck.

Although pipe rotation definitely enhances hole cleaning, its implementation has certain limitations. For example, rotation cannot be induced during angle building while using a downhole motor (i.e., in sliding mode). With the new rotary steering systems, this is no longer a problem.

Underbalanced drilling & Rotary Steerable RSS System

Underbalanced drilling (UBD) has improved penetration rates and reduced formation damage in horizontal wells. Drilling with air, nitrogen, or aerated mud is the primary method of providing an underbalanced fluid column. The use of these highly compressible fluids causes problems with mud motors. First, the air’s compressibility significantly affects the motor’s efficiency. Second, the motor over-speeding significantly increases lateral vibration problems detrimental to the bits, motors, and steering equipment. Rotary-steerable directional systems can eliminate many problems from running a PDM with a highly compressible fluid.

Capital costs

In offshore drilling rigs, Rotary-steerable System will assist in reducing the number of wells. This is due to increasing the achievable departure for extended-reach wells. Capital costs and delayed production associated with setting up a platform (platform rigs) are often the greatest economic driver for developing an offshore field.

Problem formations

There are cases where formation considerations make operating steerable motor systems particularly troublesome. One example includes situations where the operating window between lost circulation and maintaining hole stability narrows. Even though the actual well trajectory may not be challenging, the equivalent circulating density (ECD) variations between sliding and rotating the steerable motor may become great enough to make it tedious, if not impossible, to stay within the window. It only takes a few incidents of packing-off or lost-circulation problems (lost circulation material) to pay for the additional ECD stability afforded by rotary-steerable systems.

When to Use RSS In Drilling

- ERD wells that are beyond current comfort zones;

- Vertical wells where directional control is difficult;

- Designer wells where sliding limits achievable targets;

- Deep, hot, directional wells where motors have problems;

- High build rate, small diameter re-entry work;

- Deep wells to reduce torque and drag generated at the surface

- Wells where slide drilling causes high ECDs / wellbore stability problems;

Operating Principles

Two operating principles are often referred to when discussing rotary steerable systems – “Push the Bit” or “Point the Bit”.

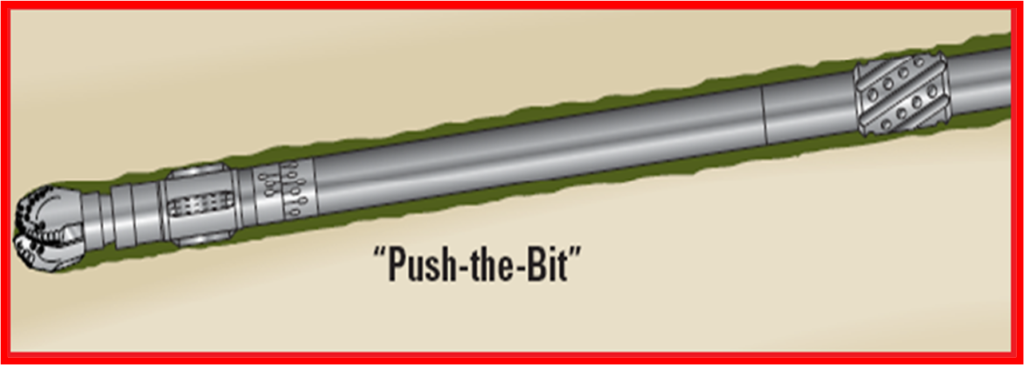

Push The Bit Operating Principle

A pure “push the bit” rotary steerable system steers simply by applying a side load to the bit – usually using pads close to the bit to apply this load. This forces the bit’s outer cutting structure and gauges to cut sideways into the formation. This will drill a curved hole in that direction, therefore, achieving the desired well trajectory. Systems employing this principle are restricted to concise gauge bits (typically less than 2″ gauge length) where the gauge is set with an active cutting structure. While these systems are agile, permitting a quick and precise response to any required changes in wellbore deviation, the short gauge bits used by these systems may drill a “spiraled hole” when high side-loading is applied.

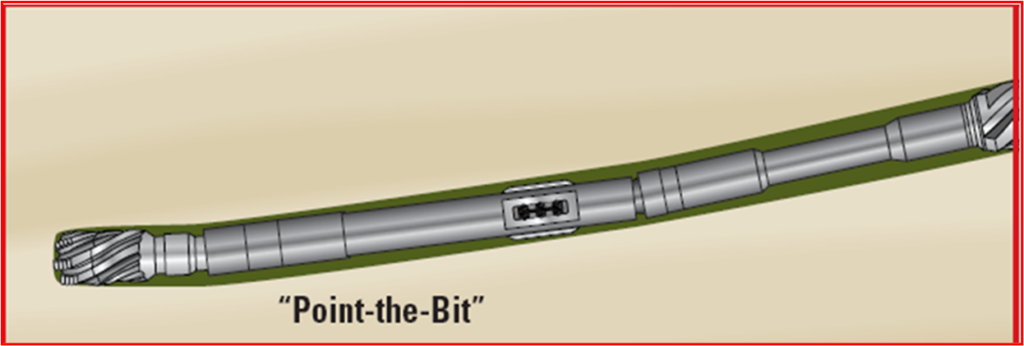

Point The Bit Operating Principle

Point-the-bit systems use the same principle as is employed in bent-housing motor systems. A pure “point the bit” RSS rotary steerable system steers by precisely pointing (tilting) the bit in the direction the well path needs to be steered. In doing so, the drill bit’s face points perfectly in the required direction, and there is no side loading on the bit. The advantage of this operating principle is that we can use longer gauge bits to avoid hole spiraling. Unfortunately, these systems are slower to respond to required trajectory changes, and the overall dogleg severity capability is typically lower than that of a “push the bit” system.

Factors to Consider When Choosing RSS:

- Cost;

- Required hole size;

- Required build rate;

- Commercial experience and track record;

- Current MWD contracts;

- Possible operating constraints;

- Available data from comparison wells

Screening Criteria For The Use of Rotary Steerable System:

- Directional control is essential;

- Formations with strong directional tendencies;

- Large ratio of sliding time to rotating;

- Beyond the ability to slide;

- Multiple targets;

- Significant azimuthal turns at high inclination;

- Tortuosity in the tangent section causes excessive torque and drag;

- Wells where deep directional work is avoided due to anticipated problems;

- Casing/completion running is difficult due to the tortuous hole;

- Extensive reaming is required due to hole cleaning problems;

- Differential sticking is a concern;

- MWD tool failures occur due to motor vibration;

- Directional control takes precedence over making hole;

- Roller bits are used instead of PDC bits to improve ‘steerability.’

Rotary Steerable Systems In The Market

The top three different RSS rotary steerable drilling systems are:

- The PowerDrive by Schlumberger.

- Baker Hughes Inteq developed the AutoTrak RSS system.

- The GeoPilot RSS from Halliburton.

References

- ROTARY-STEERABLE TECHNOLOGY—Part 1 Technology gains momentum; Tommy Warren Amoco Production & Exploration Technology Group Tulsa

- Shell Manual For Directional Drilling

- PetroSkills – Deflection Tools Course