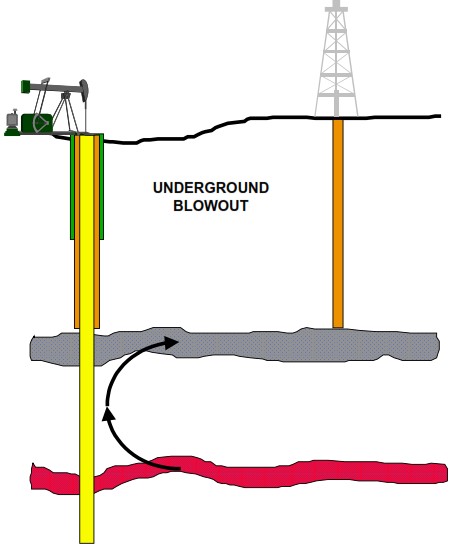

An underground blowout is the flow of formation fluids from one zone to another. Most commonly, we can recognize the underground Blowout by a lack of pressure response on the annulus. And this response will be while pumping on the drill pipe or by a general lack of pressure response. The underground Blowout can be most difficult, dangerous, and destructive. It can be most difficult because the conditions are not clear and can evade analysis. Often, the pressures associated with an underground blowout are nominal, resulting in a false sense of security.

Underground Blowout: an uncontrolled flow of gas, salt water, or other fluid out of the wellbore and into another formation that the well bore has penetrated.

Schlumberger Glossary Definition

Definition

Underground Blowout is the uncontrolled flow of formation fluids entering the wellbore at one point and leaving the wellbore at any point other than the surface. The flow is most likely to travel up the wellbore before exiting but can occasionally travel down the wellbore to the receiving formation.

Causes

- While gas kick migration or circulating kick out of the well, when the pressure increases above the strength at the weakest point, the formation at that point will fracture. Furthermore, the risk of an underground blowout is high.

- Long open hole section.

Ex:

There is often a chance, particularly with relatively long open hole sections beyond the last casing shoe, that bullheading could break down the formation at the shoe rather than at the producing formation. In this event, rather than killing the well, this procedure may aggravate the development of an underground blowout that could pose risks to nearby wells in communication with the formations involved

- Bad killing practice

Ex:

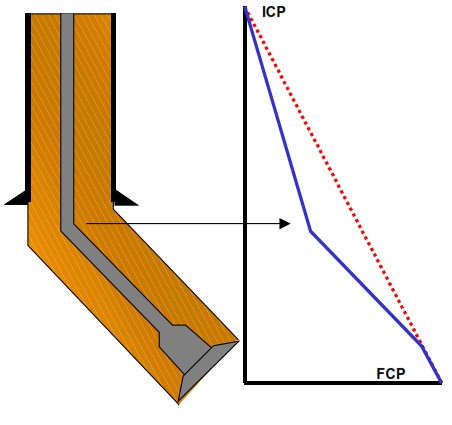

In a deviated well with a uniform string using the “Wait and Weight” method, the red dotted line represents the theoretical pressure graph when circulating kill fluid to the bit from ICP to FCP. The blue line represents the true pressure graph to follow using the “Wait and Weight” method. Using the theoretical pressure graph, we can see that while circulation kill fluid to the drilling bit, the well is in overbalance, leading to severe further well control problems like lost circulation that can lead to underground Blowout. See Fig below.

Other causes

- A delay in shutting in the well may cause a large gain volume. (hard shut-in, soft shut-in)

- Loss of circulation may cause an underground blowout: The hydrostatic head at a permeable, exposed formation drops below the formation pressure. Fluids then produce into the well and flow uncontrolled into the broken zone. It is a great challenge to control the situation. Moreover, it is possible to lose the well below the formation.

- When pressure due to drilling fluid weight approaches the fracture gradient of the highest exposed formation, it is good practice to set casing (casing setting depth). Failure to do this has been the cause of many underground blowouts and lost or junked wells.

- After shutting in shallow gas, kick instead of diverting it (Drilling Diverter).

- Alot don’t recommend drilling with a mud cap through a hydrocarbon-bearing reservoir, as we may not be able to control a kick from the surface (resulting in an underground blowout).

Underground Blowout Risks

It can be dangerous because some associate danger with sight. In many instances, there is no physical manifestation of the underground Blowout. If a well is on fire or blowing out at the surface, it commands respect. However, if the same well is blowing out underground, it is more easily to ignore. Since we may not see the underground Blowout, we must respect it properly.

If the underground Blowout is within 3,000 to 4,000 feet of the surface, there is the possibility that the flow will fracture to the surface outside the casing. The potential for cratering is high, and the crater could be anywhere. It can be the most destructive when the crater is under the drilling rig or drilling platform. The world lost entire rigs (Types of Rigs) and production platforms into cratered underground blowouts. (Also check: Biggest oil & gas drilling rigs)

If the casing depth is deep, there is the potential for extremely high surface pressures, which might fail the surface equipment or rupture the exposed casing strings. If we have been using shear BOP rams, there is the potential for even more problems with surface pressures and casing string types.

Challenges We May Face

Underground blowouts are generally more challenging than surface blowouts as we are not able to discover the influx volume & composition. Further, the condition of the wellbore and tubulars involved are not reliably descriptive. The well-control specialist is confronted with the necessity of analyzing and modeling the Blowout and preparing a killing sheet & procedure. Also, there are a limitations in the tools of analysis and modeling. In addition, the tools and techniques should be limited to only those necessary since any wireline operation is potentially critical. With the underground Blowout, we cannot know the wellbore condition with certainty. Furthermore, the risk of sticking (also check: pipe sticking) or losing wire and tools (wireline fishing). Stuck or lost wire and wireline tools can be fatal or limit future operational alternatives. Since the consequences of an underground blowout can be severe, we shall answer critical questions:

- Should we shut in the well?

- Should we vent the well to the surface?

- Is the flow fracturing to the surface?

- Can the losses be confined to a zone underground?

- Is the casing capable of containing the maximum anticipated pressures (MAASP in Drilling)?

- Should we displace the casing annulus with mud (Mud displacement) or water?

- If we want to displace the casing annulus, what should be the density of the mud?

- Is the flow endangering the operation and the personnel?

Underground Blowout Indications

The following are indications of an underground blowout.

- A sudden break in surface pressures during the initial build-up to equilibrium.

- Rapid fluctuations in casing pressure. (Initial shut-in casing pressure decreases)

- The initial shut-in casing is less than SIDP.

- Drill string on a vacuum.

- No change in casing pressure while killing the well or circulating the influx out.

Analyzing The Underground Blowout Situation

Unlike classical pressure control, there are no solutions that apply to all situations. We can usually analyze the underground Blowout utilizing surface pressures and temperature surveys. The noise log needs to be clarified. In all instances, we shall consider carefully the safety of the personnel working at the surface and the potential for fracturing to the surface.

It is essential to assess the hazards (Oil Rig Hazards) associated with the conditions at the Blowout. In temperature survey analysis, it is recognized that the flow TEMP will be the same as the source reservoir TEMP. Therefore, if the flow is from a deep into a shallow formation, there should be an abnormally high temperature in the loss zone.

Surface pressures are a reflection of the conditions downhole. If the surface pressure is high, the zone of loss is deep. Conversely, if the surface pressure is low, the zone of loss is shallow. If the density of the annular fluids is known, we can calculate the depth of the loss zone.

The noise log is helpful in some instances. We can generally detect the flow of fluids with sensitive listening devices. However, in some instances, the Blowout was unrecognized by the noise log, while in other instances, the interpretation of the noise log indicated the presence of an underground flow when there was none. Applying these principles is best understood by considering specific field examples.

Killing Of Underground Blowout

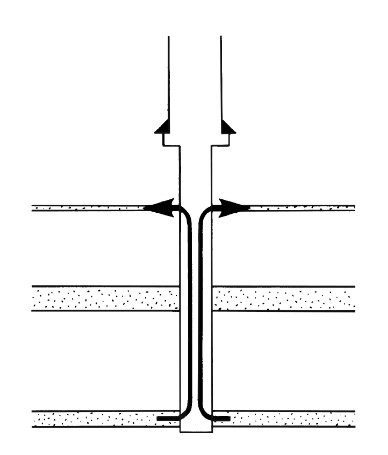

The method of killing an underground blowout depends on many factors. A stuck drill pipe (differential sticking or Mechanical sticking) will complicate the situation. If an underground blowout is even suspected, the first thing that we should do is to locate the zones kicking and taking fluid. We can allocate the problem zone with a temperature survey inside the drill pipe.

If the drill pipe is free, usually, its end is near the zone that is kicking, usually at the bottom of the hole. Sometimes circulating a very heavy mud pill between the two zones can shut off the flow. The pill’s volume should exceed the hole volume between the two zones. It is sometimes desirable to simultaneously pump mud down the annulus.

Barite Plugs

The most successful method of controlling a high-rate underground blowout is to spot a barite plug (approx. 150 PCF) just above the flowing zone instead of lost circulation material. Course-ground barite is better suited for this application than finer grind because of faster settling. We may require several barite pills to shut off the flow in extreme cases.

The barite plug consists of barite, water, lignosulfonate, and caustic soda. The lignosulfonate deflocculates the slurry and allows the settling of the barite to form a plug in the wellbore. The caustic soda provides a high pH (10-11) environment for the lignosulfonate to be effective.

- A typical formulation for a 150 PCF barite plug is as follows,

- 0.54 bbl water

- 690 lbs/bbl barite

- 8 lbs/bbl lignosulfonate

- 1 lb/bbl caustic soda

Slurry volumes will depend on the open hole interval and severity of the kick. Typical volumes range from 40 bbls to 400 bbls.

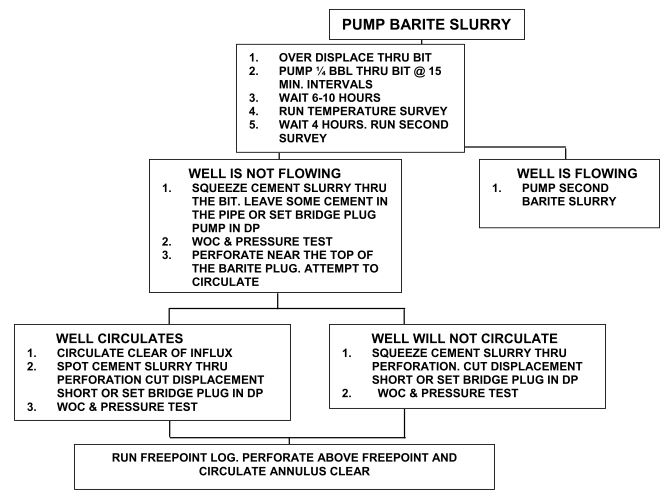

The following flow chart summarizes the operations of controlling an underground blowout with barite plug(s) and cement plugs. This method involves cementing a section of the drill string or bottom hole assembly in place.

Conclusion

- If no kick margin is provided, taking a kick at the casing setting depth is impossible without causing a fracture and a possible underground blowout. (also check: kick tolerance)

- Previous underground blowouts can produce charged formations.

- After a kick is detected and the well shut in, no more formation fluid can flow into the wellbore after pressures stabilize (except in the case of an underground blowout)

- With shallow casing seats, kicks must be diverted and not shut in. Shutting the well in on shallow gas sand can result in an underground blowout and gas communication to the sea floor.

- If the sub’s pressure reaches the maximum permissible surface pressure, we have to decide whether to let the well blow out underground or vent the well to the sub.

- A shut-in well blowing out underground is difficult to analyze and often more challenging to control.

- Analysis of the gain in the surface volume in consideration of the casing pressure is critical in defining the potential for an underground blowout.

- That is, if the shut-in annulus pressure is less than or equal to the shut-in drill pipe pressure, the density of the fluid which has entered the wellbore must be greater than or equal to the density of the mud in the wellbore! Further, when the density of the drilling mud in the wellbore is more than 10 ppg or when the influx is known to be significantly hydrocarbon, it is theoretically not possible for the shut-in casing pressure to be equal to or less than the shut-in drill pipe pressure. Something is different downhole than assumed in the mathematical U-Tube Model, and that something is usually that lost circulation has occurred, and the well is blowing out underground.

- Failure to consider the migration of the influx will usually result in unacceptable surface pressure, ruptured casing, or an underground blowout. One of the most severe and frequent well control problems encountered in the industry is the inability to bring the influx to the surface without experiencing an additional influx or causing an underground blowout.

- One of the primary problems in well control is circulating a kick to the surface after we shut in the well without losing circulation and causing an underground blowout.

- In recent years, it has become apparent that the Driller’s Method, while simple, may result in an underground blowout that could have been prevented.

- Wait, and Weight Method can be a good alternative well-control displacement procedure when casing shoe pressures approach fracture pressures, and an underground blowout threatens.