The tripping pipe can be defined as running in or pulling out of the hole with the drill string. In this article, we have prepared a complete guide for who needs to learn its operations on the surface and who needs to understand its procedures to prevent any unforeseen problems.

During such trips, the potential exists for a significant reduction in bottom-hole pressure due to the following effects:

- Reductions of the Equivalent Circulating Density as the mud pumps are stopped.

- Swab pressures due to pipe motion.

- Reduction in the height of the mud column as drill pipe is removed from the well.

The procedures required to deal with an influx when the pipe is off the bottom are not as straightforward as when the pipe is on the bottom. Therefore it shall be ensured that the well is stable before initiating a trip out of the hole and that the correct tripping procedure is strictly followed.

PPE Necessary for Tripping PiPe Operations

Many accidents on the drill floor while pipe tripping involve using tongs. Injuries result from being caught between tongs and being struck by swinging tongs. All tongs should be securely attached and anchored. Tong safety lines should be of sufficient length, preferably allowing a 90° breakout angle between the lines, but short enough to prevent over-rotation of the tongs.

The tong jaws, including the dies, should be inspected regularly for size and condition. Tongs shall be maintained and replaced well before they become worn to the point of being unsafe. Hinge pins should be secured by a nut locked in place by a device such as a split pin.

All tong counterbalances and parts thereof shall be so restrained, guarded, or located as to prevent them from falling or striking crew members if the suspension line breaks. Remember that suspension lines are classified as lifting devices and should be inspected, certified, and color-coded in the same manner as slings. Their history should be recorded in the sling register.

While changing tong/slip dies, or tripping operations, ensure that:

- goggles are worn as hammer blows can cause splinters to develop

- gloves are used

- usual PPE as coveralls & safety shoes

- the working area is clear and unaffected by other operations in progress.

Back-up post-failure has potentially severe consequences. A systematic approach to backup post-inspection and planned preventive maintenance is required, including MPI inspections on a six-monthly basis. They should also be included in the weekly/monthly drilling equipment inspection checklist

Pre-Trip Checklist & Safety Meeting Prior Tripping Pipe

Ensure that the crew is up to strength and that individuals know the tasks to be carried out. A communication system should be operational between the rig floor and the monkey board. Note the following:

- Before starting a trip, ensure that the equipment required is serviceable

- and avoid using the rotary table to spin out pipes. Use a pipe spinner.

- Never make up a connection with the rotary table while using a tong as a backup; the shock loading could result in the breaking of the backup wire

- Never attempt to stab a single into the mouse hole when the Driller is lowering the traveling block

- ensure the crown safety device is correctly installed and adjusted at the start of each tour and following drilling line slipping or cutting operations

- monitoring of mud levels, flow checks, and use of the trip tank should be part of the routine tripping procedures in and out of the hole

- do not install wipers until the Driller is satisfied with the hole condition. They act as obstructions to the visual checking of mud levels

- while pipes are being moved from or to the rig floor, the catwalk should be kept free of personnel

- when hole conditions allow, pump a heavy pill to avoid pulling the ‘wet’ pipe.

Before Tripping

Considerable preparation is required before the trip is commenced.

The following are among the most essential actions that should be carried out before tripping:

Circulate the hole

- Circulate bottom-up until the hole/shakers clean from cuttings at the maximum allowed flow rate, reciprocating and rotating the string to avoid prolonged circulations at a point.

- The mud should be conditioned to ensure that tripping will not cause excessive swab/surge pressures. Conditioning means that the rheological characteristics are those planned for the actual hole section and that the mud weight in and out is even.

- Any entrained gas or cuttings should be circulated out.

- The mud weight should be such to ensure an adequate overbalance during the trip.

Determine the maximum pipe speed.

- Swab/surge pressures should be calculated at various tripping speeds using the appropriate formulae. Calculation of swab/surge pressures is typically available from the mud logging Service Provider.

- The maximum average pipe speed should be selected, considering the estimated overbalance or trip margin.

Line up the trip tank

- A trip tank must be available on every rig and be complete with an indicator(s) of the trip tank level, visible from the Driller’s position. The trip tank level must also be monitored from the Mud Logger‘s cabin.

- It is considered unsafe to trip without a trip tank, so spare parts for the hole-fill pump/motor should be kept at the rig site.

- So that maximum use is made of the trip tank on trips in and out of the hole, a trip sheet shall be used to record the mud volumes required to keep the hole full.

Fill in the trip sheet.

- The Driller should fill out a trip sheet on every trip. Table 2.1 shows an example of a trip sheet. The basic requirement for a trip sheet is that a clear method of comparing the calculated with actual hole fill volumes is provided. The cumulative discrepancy between the two values should also be recorded. The trip sheet for the last trip out of the hole should be available for comparison.

Provide the Driller with the necessary information.

- The Driller should be told the reason for the trip.

- The Driller should be told of any indicators of increasing pore pressure or near balance identified during drilling, before or since he came on shift.

- Troublesome zones should be highlighted where stringers, dog legs, and washouts may be present based on the available information.

- The Driller should be fully aware of the procedures to be adopted in case of a kick while tripping.

- The maximum allowed overpull, also considering the weight of the drill string, shall be noted to prevent mechanical stuck pipe (also check free point calculation for stuck pipe).

- The Driller should be aware of the procedures to prevent the occurrence of differential stuck pipes.

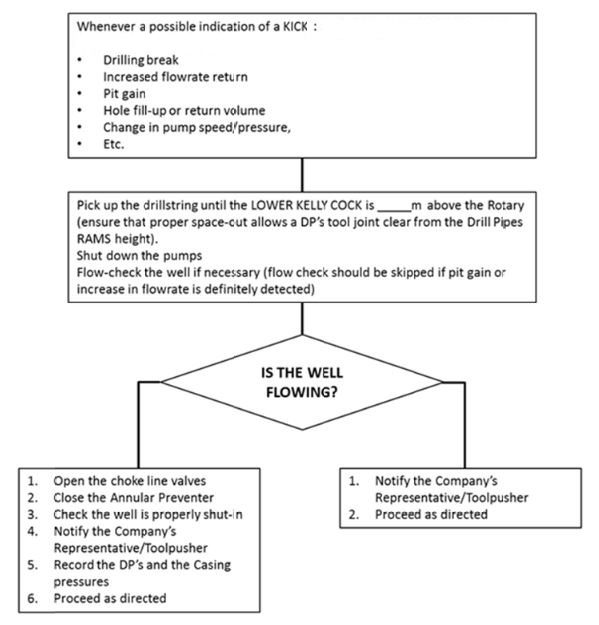

- An example of the standing orders that should be provided to the Driller is shown in Figure below.

Drill floor preparation

- Crossovers should be available on the rig floor to allow a full-opening drill pipe safety valve to be made up to each tubular connection in the hole.

- A drill pipe safety valve (kelly valve) should be available on the rig floor. It should be kept in the open position.

- A backup safety valve, such as a Gray valve, should be available close to the rig floor. This valve should only be used if the drill pipe safety valve does not hold pressure or if stripping operation in the hole is required and no dart sub (Drilling Subs) is fitted.

- The rig crew should be completely familiar with and trained in their responsibilities in the event of a kick.

Surface Tripping Pipe Operations

Making pipe Connection

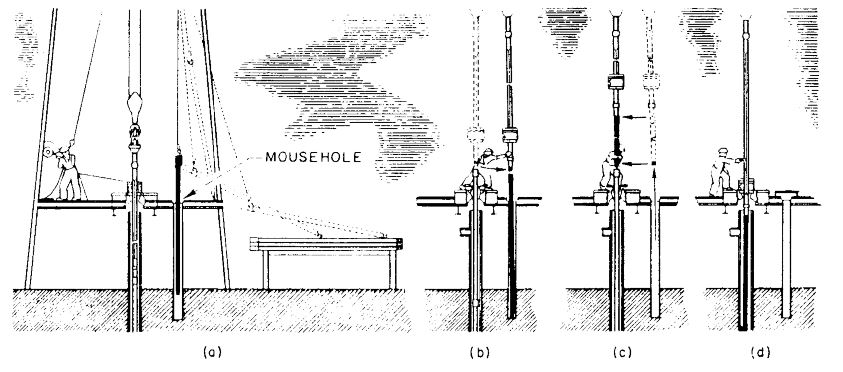

When the rig kelly, or top-drive system, has drilled down, it is withdrawn, and a new length of drill pipe is added. Refer to Figure 2 (a through d) for the following text description.

In (a) the kelly is near the “kelly down” position, where another pipe joint must be added. The new length of pipe has been placed in the “mousehole”, ready to be connected. We use the mousehole to store the next measured pipe joint until it is required for threading into the drill string. The crew breaks out the kelly so it can be swung over to the pipe joint in the mousehole, as in (b). The kelly is made up on the joint and tightened with the tongs. In (c) and (d), the new joint of pipe is picked up, swung over to the pipe hanging on the rotary table, and “stabbed” into the drill string. The new pipe is screwed into the drill string, tightened with the tongs, and lowered into the borehole to drill another joint length.

The difference with “top drive in drilling rig” systems is that the kelly is unused, and pipe stands are drilled instead of joints. The following stands to be drilled may be placed in the mousehole or left standing in the monkey boards.

First Stage Of Tripping Pipe

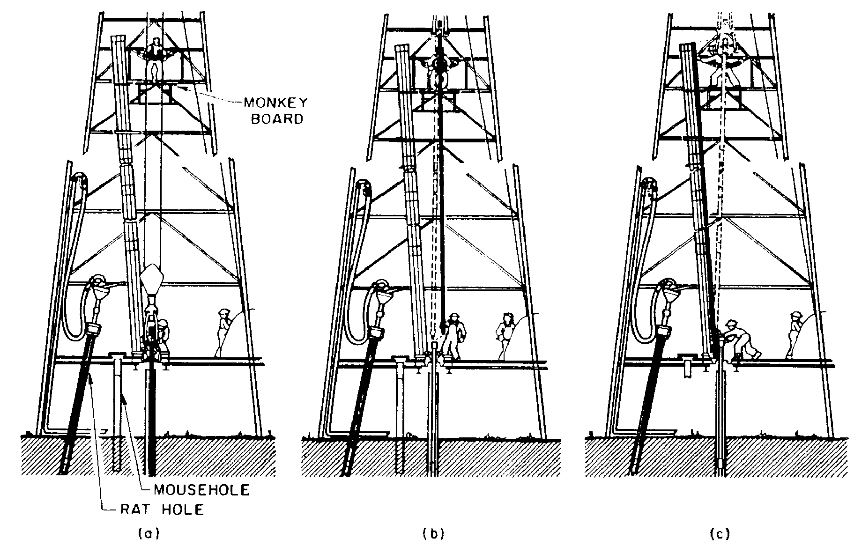

When making a trip, the drill pipe is handled in stands of three joints each (approximately 93 feet). The pipe is removed from the borehole and set back on the rig floor. Refer to Figure 3 for pulling the pipe out of the hole (tripping out). The kelly, rotary bushing, and swivel are placed in the rathole during the trip, as seen in (a). With the Kelly out of the way, the elevators are latched around the pipe just below the tool joint’s box end.

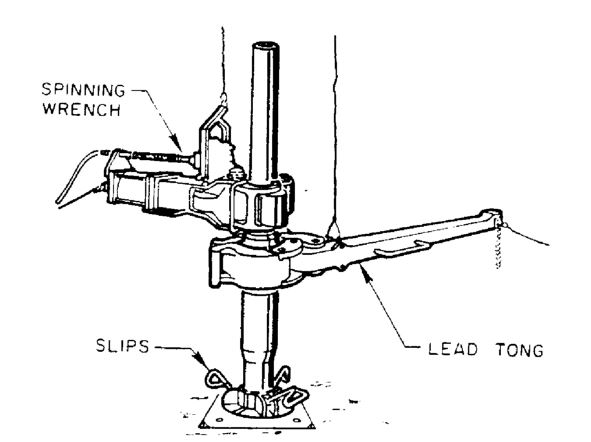

The drill pipe tool joint‘s box end provides a shoulder for the drill pipe elevators to pull against. The pipe is then pulled from the borehole, and after being secured in the rotary table (using the slips), the connection is loosened with the break-out tongs. A spinning wrench (power tongs) is commonly used to unscrew the pipe at this time. This is illustrated in Figure 4.

Second Stage Of Tripping Pipe

The top of the stand, which has been pulled past the derrickman (standing on the monkey board), has a rope thrown around it. The bottom of the stand is swung to one side of the drill floor where it is set down (Figure 4-2c), and the rig derrick man racks the stand in the “fingers” in the monkey board to secure it.

The drill collars and drilling bits are the last to come from the borehole. The master bushing may have to be removed to allow the large-diameter collars to pass through the rotary table. When the bit appears, the master bushing is replaced, and a “bit breaker” is placed on the rotary table. The bit is loosened and removed from the bit sub using the breakout tongs.

Note:

- Tripping in is just the reverse procedure of tripping out.

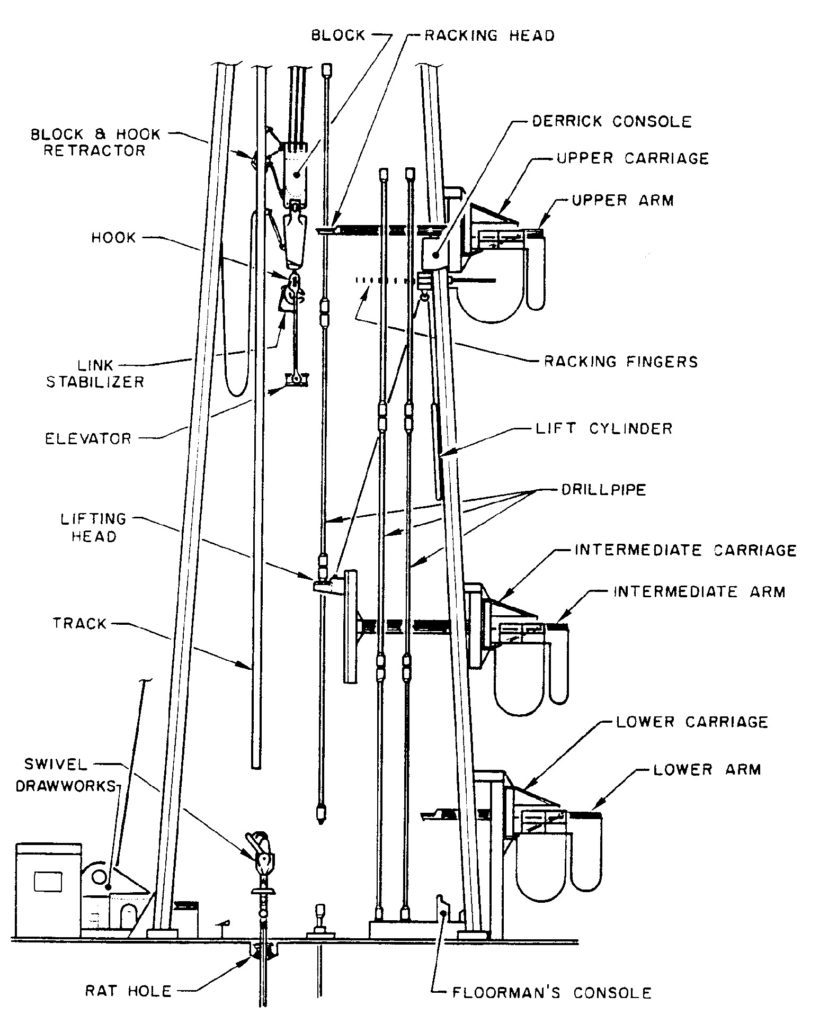

- Some rigs have a pipe handling system to speed up pipe movement during tripping operations (Figure 5)

Downhole Pipe Tripping Procedures

Having completed the preparations outlined in the previous section, the trip out of the hole can be started. The following procedure is proposed as a guideline:

- Flow check the well with the pumps off to ensure that the well is static.

- Pump a slug. This enables the pipe to be pulled dry and the hole to be accurately monitored during a trip.

- Well operations Supervisor, the Toolpusher, and/or the Directional Driller shall be on the rig floor during the initial stage of the trip out of the hole (e.g., the first ten stands at least) and during any expected problematic interval.

- For the first 5-10 stands off the bottom, monitor the hole through the rotary. This is to check any fluid drop in the annulus level as pipes are removed from the hole. The pipe wiper should be installed only after these stands have been pulled. The trip tank should not be overfilled at this stage to ensure that swabbing is noticed, should it occur. The circulating pump should be switched off and the hole filled from the trip tank.

- Circulate the hole across the trip tank and continue to trip out, monitoring hole volumes with the aid of the trip sheet.

- Conduct a flow check when the BHA is into the casing shoe.

- Conduct a flow check before pulling the BHA through the Blow Out Preventers stack.

Slug Pill Calculations

Note: the slug shall not be pumped until a clear indication of well static has been achieved. It is suggested to slug pipes only after the well has been flowing checked following the first 5-10 stands pulled. The following formula can be used to calculate the volume of the slug to ensure a length, L, of dry pipe:

Vsl = (MW x L x Cp) / (MWsl-MW)

Where:

- Vsl = volume of the slug, L (bbl)

- L = length of dry pipe, m (ft)

- Cp = internal capacity of pipes, L/m (bbl/ft)

- MW = mud weight in the hole, kg/L (ppg)

- MWsl = slug weight, kg/L (ppg).

Generally, the slug should be mixed to maintain a minimum of 2 stands of dry pipe. It is important to accurately displace the slug to the pipe. In this manner, the Driller will know the weight, depth, and height of the slug during the trip.

Important Notes

Be aware that the required hole fill volume per stand of heavy-weight drill pipe and drill collar will be greater than for drill pipe as the Bottom hole assembly BHA is removed from the hole.

If unsure of the overbalance, consideration should be given to conducting a short round trip. Once back on the bottom, the overbalance can be assessed from the level of the trip gas at the bottom up.

If the hole does not take the correct amount of fluid at any stage in the trip, a flow check should be carried out. If the flow check indicates no flow and the cause of the discrepancy cannot be accounted for at the surface, the string should be returned to the bottom while paying particular attention to displacement volumes. After circulating bottoms up, it may be necessary to increase the mud weight before restarting the trip out of the hole. If the flow check is positive, the well should be shut-in procedures according to the procedure indicated in the standing orders. Subsequent action will be dependent upon the conditions at the rig site.

Tripping Procedures With Oil-Based Muds

When oil-based muds are used, gaseous fluids go into solution with the mud at high temperatures and pressure. Experience has shown that once an influx has gone into the solution, it will not break out until the bubble point is reached, typically at 70-105 kg/cm2 or 1000-1500 psi (this will depend on the specific fluids).

The possible consequence of this is that a small influx that is undetected at depth may suddenly break out of solution close to the surface, suddenly releasing the gas phase and thus resulting in a significant reduction in hydrostatic pressure in the well and possibly representing a danger for persons working on the rig floor.

Consideration should also be given to the possibility of thermal expansion of the mud at high temperatures. This can cause a reduction in effective mud weight and, hence, the overall hydrostatic head. It is, therefore, recommended that tripping procedures are modified to take account of this potential problem when oil-based muds are used in the following situations:

- When drilling or coring in a potential pay zone,

- On the prediction of an increase in pore pressure,

- On detecting significant levels of gas in the mud.

Follow The Procedure

In these circumstances, the following procedure is recommended before pulling out of the hole:

- Flow check the well.

- Circulate bottoms up.

- Check trip to the shoe monitoring hole volumes.

- Flow check at the shoe and run back to the bottom.

- Circulate bottoms up.

- If necessary, increase the mud weight and perform a further check trip.

- If you are tripping out, close in the BOP and circulate through the choke when the potential influx is about 500 m (1600 ft) below the stack, watching for any pit gain.

This procedure can be relaxed if sufficient experience and confidence in the operations have been achieved.

Tripping Procedures for HT/HP Wells

The mud will be circulated and conditioned until the Mud Engineer is satisfied that the mud weight is consistent, and the rheology will ensure minimum swab and surge pressures. The Well Operations Drilling Supervisor will review the final mud properties before the trip starts.

- Before tripping, perform a 15-minute flow check across the trip tank to ensure the well is stable. On floaters, ensure no crane movements while performing the flow check.

- Conduct a short (5-10 stands) check trip; do not pump a slug or pump out of the hole. This may be as little as 2 or 3 stands if the tight hole has been experienced further up the well.

- Start pulling out of the hole while monitoring the fluid level in the trip tank. Do not fit a pipe wiper.

Note: Do not persist with the check trip if the hole pulls tight. The pipe typically will be pumped out of the hole on an entire trip. RIH to the bottom and carry out the flow check procedure.

Firstly, If the hole does not take the correct volume of fluid:

- Stop tripping.

- Install a full-opening valve.

- Flow check the well for 15 minutes across the trip tank. If in doubt, shut in well and observe pressures.

- Once back on the bottom, circulate the bottom up.

Secondly, If there are no problems while pulling out of the hole on the check trip:

- Perform a flow check for 15 minutes across the trip tank.

- RIH to bottom monitoring hole volumes and taking into account the surge pressures. Circulate bottoms up.

- If gas breaks out, the trip margin may be too low. If necessary, increase the trip margin and perform a further check trip, as outlined previously.

- Once a safe trip margin has been established, drop the survey barrel, if so required, and start the first stage of the trip out of the hole to the shoe.

- Pump out of the hole to the shoe. This will prevent any problems with a slug if any circulating and back reaming have to take place before the shoe is reached.

- The pump rate for the trip should be at a slower rate than that of drilling.

- At the shoe, perform a further 15-minute flow check across the trip tank.

- Pump a heavy slug to avoid a wet trip and resultant uncertainty concerning fluid volumes.

- Calculate the slug size and return the volume to give two stands of dry pipe.

- Allow the slug to stabilize with the top drive disconnected and ensure that the correct volume of fluid returns, as the slug equalizes.

- Continue to trip out of the hole, following the trip schedule as calculated in the trip margin calculations.

- Carry out another flow check, before the BHA is pulled through the BOP stack.

If the trip is interrupted for any reason, install the drill pipe safety valve.

Hole Fill Pump Failure

If the hole fill pump fails during the trip, do not fill the hole through the drill pipe. Whilst the drill string is out of the hole, the shear rams (also check: BOP Rams) will generally remain open. The well will be monitored by circulating with the trip tank. If the shear rams are closed for any reason, the well should be circulated down the kill line and up the choke line with the trip tank.

Running 7″ Liner

If a 7” liner has been run, the reduced clearance between the drill string and the liner will increase the likelihood of swabbing while tripping. For this reason, the length of the trip, performed by pumping with the top drive, should extend up to the top of the 7” liner. When pulling out of the hole with a tapered string, i.e., 3½”-5”), 15 additional minutes of flow check will be carried out:

- When the bit is at the liner overlap.

- Before the smaller diameter pipe enters the BOP.

References

- Shell EP 95-0210 HSE manual.

- Baker Hughes Oil Field Familiarization Book.

- Eni Drilling operations manual.