As we discussed previously, coiled tubing gains wide popularity, especially in workover operations due to its lower cost and wide applications. In this article, we shall provide Halliburton, Schlumberger, NOV, and Baker Hughes handbooks & manuals PDF to assist engineers and operators to understand more about coiled tubing equipment and operations. We think you might be intersested to read more about the drilling data handbook.

Halliburton Coiled Tubing Handbook

Standard job procedures enhance Halliburton operations worldwide by increasing safety, communication, and performance on the job site. The procedures included in this handbook are designed to establish guidelines to match coiled tubing equipment to the type of work being performed.

The Halliburton Coiled Tubing handbook PDF contents are as follows:

- Coiled Tubing Safety

- Maintenance and Repair

- Pre-Job Planning and Preparation

- Coiled Tubing Unit Rig Up

- Coiled Tubing Operations

- CT Well Control Equipment and Test Procedures

- Operating in Extreme Conditions

- Contingency or Emergency Operations

- Coiled Tubing Management

- Hydraulic Pump Pressure Settings

- Alternate Stabbing Methods

NOV Coiled Tubing Handbook

NOV has published its coiled tubing handbook in 2013. Their objective was to train personnel for planning and performance of coiled tubing workover, completion, and well operations safely and economically. In addition, the handbook discusses coiled tubing and its applications, with general guidelines for planning and executing other operations. The main focus of this handbook is to minimize the risks of CT operations while increasing their benefits.

CT History

- The Origin of CT

- The Evolution of CT Equipment

- CT Services

- CT Industry Status

The Tubing

- Raw Material for CT

- CT Manufacturing

- CT Mechanical Performance

- CT String Design

- CT Inspection Tools

- Repairs and Splicing

- Alternatives to Carbon Steel CT

CT Surface Equipment

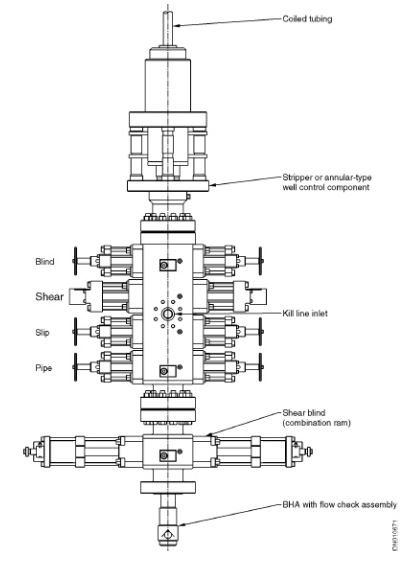

- Well Control Equipment

- Injector Head and Guide Arch

- Tubing Reel

- Power Units

- Control Cab and Operator’s Console

- CT Lifting Frame

- CT Data Acquisition System (DAS)

- Typical CT Workover Unit Configurations

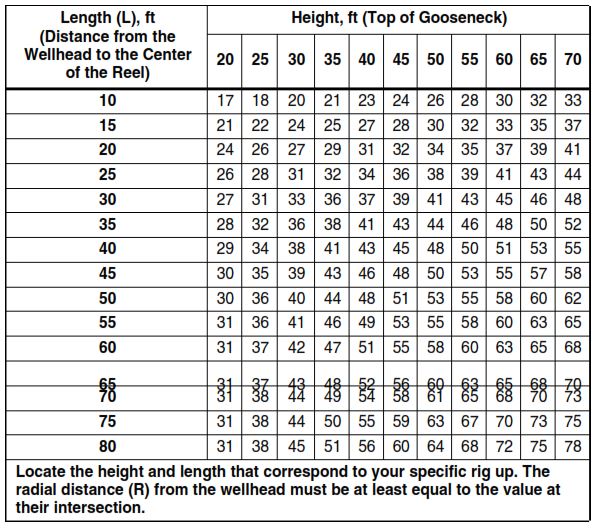

- Typical Location Layouts

Coiled Tubing Subsurface Equipment Handbook—Downhole Tools

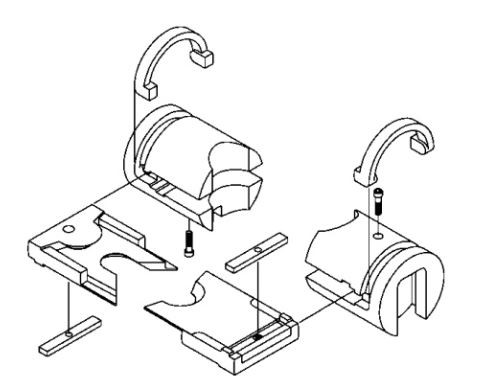

- CT Connectors

- Check Valves

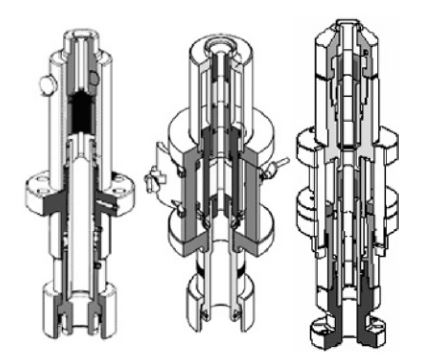

- Disconnects (Release Joints)

- Circulation and Control Valves

- Jars & Accelerators

- Straight Bars & Joints

- Centralizers

- Toolheads & Deployment Bar Systems

- Running Pulling & Shifting Tools

- Tubing End Locator

- CT Nipple Locator

- Wireless CT Collar Locator

- Indexing Tools

- CT Wash Tools & Wash Nozzles

- CT Fishing Tools

- Impact Drills

- Through-tubing completion Packers (Permanent Packers) and Bridge Plugs

Tubing Forces

- Fundamental Questions

- General Force Balance

- Force Balance for Straight Segments

- Force Balance for Segments in Curved Wellbores

- Force Balance for Helically Buckled Segments

- Pressure-Area Force

- Overall Force Balance

- Rigid Tool Calculations

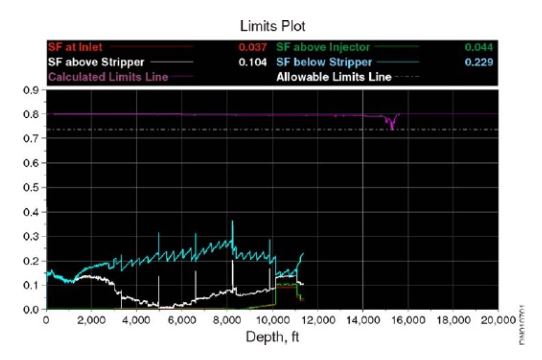

Buckling and Lock-up

- Buckling Limits

- Buckling in Vertical Segments

- Buckling in Inclined Segments

- Effects of Wellbore Curvature on Buckling

- Effects of Friction on Buckling

- Geometry of a Helix

- Post-Buckling Lock-up

CT Mechanical Limits

- Overview

- Stresses

- Limits

- Collapse

CT Working Life

- Metal Fatigue

- CT Fatigue

Coiled Tubing Hydraulic Performance Handbook

- The Fundamental Hydraulics Challenge

- The Relationship Between Pressure and Flow Rate

- Fluid Rheological Models

- Reynolds Number

- Hydraulic Friction Factor for Straight Tubes

- Hydraulic Friction Factor for CT on the Reel

- Pressure Losses in Gases

- Pressure Losses in Foams

- Pressure Losses in Liquid-Gas Flows

- The Hydraulics of Solids Transport

- Hydraulic Horsepower Requirement

- Velocity String Hydraulics

Pumping Operations

- Basic Considerations

- Removing Fill or Sand From a Wellbore

- Stimulating a Formation (Acidizing)

- Cutting Tubulars with Fluids

- Pumping Slurry Plugs

- Isolating Zones (Controlling Flow Profiles)

- Removing Scale Hydraulically

- Unloading a Well with Nitrogen

- Removing Wax, Hydrocarbon, or Hydrate Plugs

Mechanical Operations

- Basic Considerations

- Setting a Plug or Packer

- Fishing

- Perforating

- Logging with CT (Stiff Wireline)

- Removing Scale Mechanically

- Cutting Tubulars Mechanically

- Operating a Sliding Sleeve

- Running a Completion with CT

Permanent Coiled Tubing Installations Manual

- Reeled Completions

- Offshore Flowlines

- CT Umbilicals (Control Lines)

- Casing and Tubing Repairs

Non-standard CT Operations

- CT Operations in Pipelines and Flowlines

- Coping with Weight and Space Limitations Offshore

- Hydraulic Fracturing Through CT

- Subsea Well Intervention

- High Temperature (T > °F)

Coiled Tubing Drilling Handbook

- Overview

- Bottom Hole Assembly

- Downhole Motors for CTD

- Drill Bits for CTD

- CTD Rig Systems

- Drilling Fluids and Wellbore Hydraulics

- Exiting an Existing Wellbore

- Planning a CTD Operation

- CTD Procedure and Task List

- Directional Drilling Calculations

High-Pressure Operations

- Planning Considerations for HPCT Operations

- Equipment Selection for HPCT Operations

- Safety Issues and Minimizing Risk for HPCT Operations

Minimizing Risk For CT Operations

- Job Planning

- CT Simulators

- Equipment Specifications

- Pre-Job Preparation and Testing of CT Equipment

- Data Acquisition and Real-Time Monitoring

- Post-job Reports

General CT Operations Guidelines

- General Safety Guidelines

- Transportation of Equipment and Materials

- Rig Up

- BOP Operation

- Well-Site Pressure Testing

- General Operating Guidelines

- CT Running Speeds

- Pull Tests

- CT Test Runs

- CT or BHA Becoming Stuck

- Contingency Operations

- Well Control for CT Operations

- CT String Maintenance

- Deploying a Long Tool String in a Live Well

Miscellaneous

- CT Equipment Drawings

- Coiled Tubing Performance Data

- Bibliography of CT References

- Nomenclature and Abbreviations

Download

Baker Hughes Coiled Tubing Handbook

Baker Handbook offers a wide variety selection of coiled tubing conveyed intervention products, services, and solutions with which to meet individual well requirements. This handbook was developed to help our clients determine which systems and services will be much applicable to their needs. For that reason, Baker Hughes has designed the handbook to highlight system performance within eight distinct intervention areas where coiled tubing can offer a highly effective and valuable alternative. These eight categories are:

- Hole Cleaning

- Flow Management

- Well Plug and Abandonment

- Zone Isolation

- Stimulation and Fracturing

- Fishing Operations and Milling Operations

- Sand Control Completions

- Well Sidetracking and Re-entry.

Dowell Schlumberger Coiled Tubing Handbook PDF

The technical information within Schlumberger coiled tubing handbook manual PDF is intended to provide a basic understanding of the equipment, tools, processes, and design requirements associated with modern coiled tubing operations. Comprehensive and detailed information, such as that required to safely and successfully complete the design and execution of coiled tubing operations, may not be included.

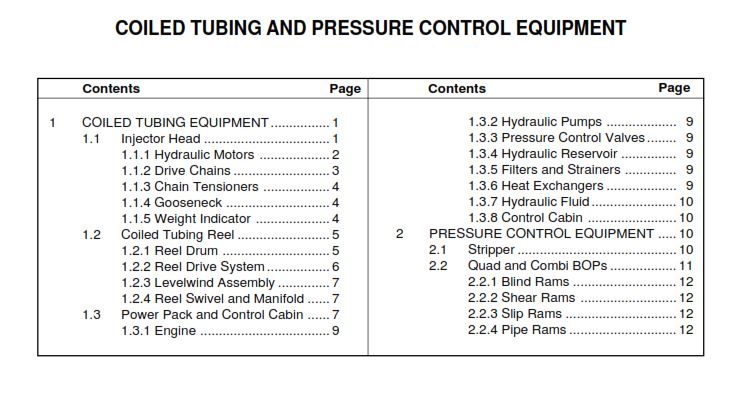

- Coiled Tubing and Well Control Equipment

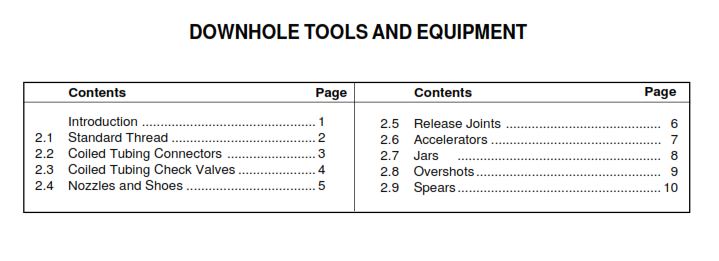

- Downhole Tools and Equipment

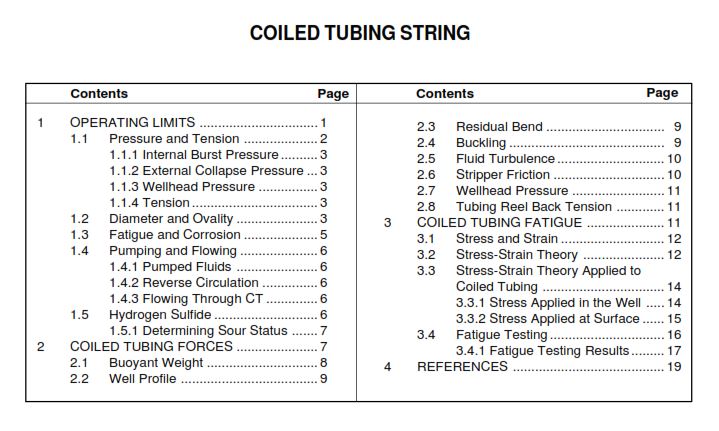

- The Coiled Tubing String

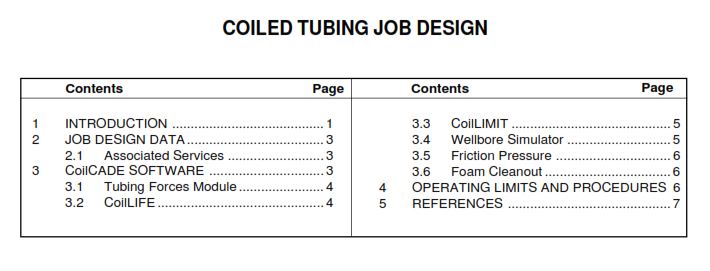

- Coiled Tubing Job Design

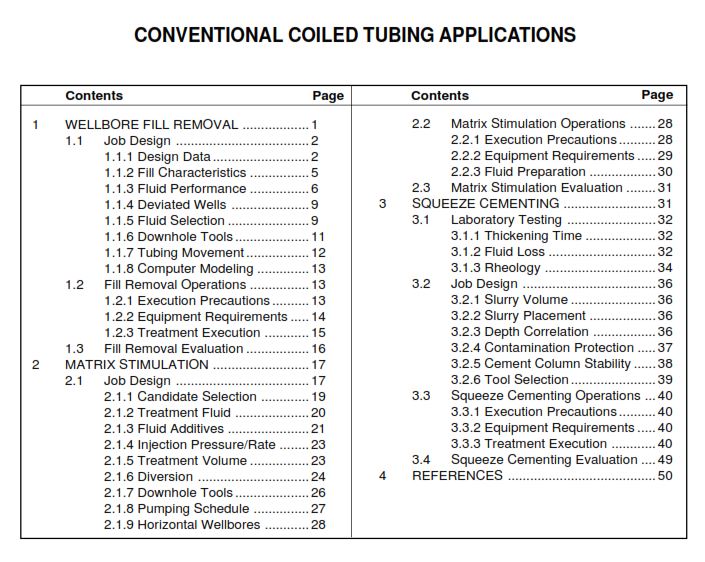

- Conventional Coiled Tubing Applications

- Wired Coiled Tubing Applications

- Coiled Tubing Completions

- Coiled Tubing Drilling

- Appendices

- Contingency Planning

- Deployment Systems

- Coiled Tubing Unit Simulator

- Supplementary Information

This is great.