It is a structured process for collecting independent information on the effectiveness, reliability, and efficiency of all systems on a rig, as well as developing plans to correct any deficiencies found. A rig audit, acceptance, or commissioning identifies critical control points that must be managed to ensure a successful outcome from the drilling unit components.

To ensure optimal results, audits are conducted during the actual operational phase, after rig installation, and before moving, allowing real-time assessment of the work between people, equipment, and the drilling process.

Any Rig Audit, Acceptance & Commissioning Guidelines include the following:

- Firstly, General information on the rig

- Secondly, Energy Sources

- Thirdly, Rig Floor, TDS Top drive in drilling rig, Drawworks Acceptance Guidelines

- Fourthly, the Mud circulation system

- Fifthly, BOP Stack, BOP Control Unit & Chock Manifold

- Sixthly, Cementing unit acceptance

General information on the rig

This information includes model, type, year of manufacture, dimensions, transportability, current location, etc.

Energy Sources

The rig audit for energy sources includes diesel drives, electric drives, generators, transformers, and lighting. Type, model, technical characteristics date of manufacture, date of revision, and availability of the main consumables of all of the above elements. In Rig Prime movers acceptance & commissioning article, you shall find detailed guidelines that will help you in such a process.

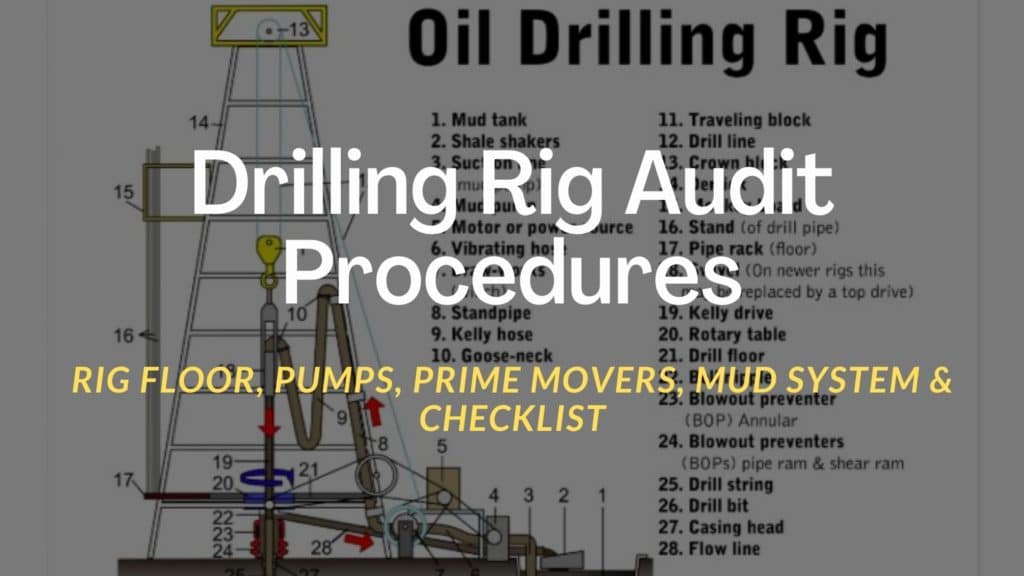

Rig Floor, TDS, Drawworks Acceptance / Audit Guidelines

In our simple Rig floor, TDS, Drawworks Commissioning guidelines, we shall cover the following: Hoisting/Auxiliary Equipment, Rotary Table and Top Drive, Emergency Generator, Rig Floor, Driller’s House (Check also Driller Job Descriptions), Rig Mast or Drilling Derrick, Tongs & Drilling Slips

Lifting equipment includes the following: winches, masts, traveling blocks, crown blocks, etc. Type, model, technical characteristics, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Rotary equipment includes the following: top drives, squares, pipe walkways, and candlesticks. Type, model, technical characteristics, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Rig floor equipment includes the following: elevators, links, keys (hydraulic, pneumatic, manual), auxiliary winches, etc. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Mud Circulation System

The mud circulation system includes Mud Pump Systems, a Low-Pressure circulation system, and Solids Removal Equipment (Shale Shakers – Desander and desilters – etc.). The rig Audit For Mud Circulating System article shall cover the essential procedures to perform a successful inspection of Mud Circulating System.

Pump systems include the following: mud pumps, their number, drill sleeves, backfill lines, and high and low-pressure supply lines. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

A low-pressure circulation system includes the following: Tanks, their number, mixing funnels, tanks for reserve drilling fluid, sand traps, filling tanks, etc. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Equipment for drilling mud cleaning includes the following: vibrating Shaker screens, their number, sludge separators, sand traps, centrifuges, degassers, etc. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Rig Audit For BOP Stack, Control Unit & Chock Manifold

For the rig acceptance of the well control equipment on any onshore or offshore rig (Check also types of drilling rigs), three main terms are necessarily got inspected:

- Chock manifold acceptance pressure test

- The Bop stack acceptance pressure & function tests

- Bop control system acceptance

The BOP and BOP equipment include the following: BOP (what, how many), wellhead connections, pressure indicators, manifolds, check valves, ball valves, pipe subs, etc. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Cementing unit acceptance

The cementing unit may or may not be a component of the drilling rig. But in all cases, we shall include it in our rig audit once it is assembled. And you can do so with the help of Cementing unit acceptance procedures article.

Other Rig Audit Terms To Check

Pipes include the following: drill pipes, casing pipes, heavy pipes, weighted pipes, light pipes, casing liners, non-magnetic pipes (NMDC), subs for connecting the above pipes, etc. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Logging equipment on the rig floor includes pressure gauges, recorder indicators, etc. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Fishing equipment (overshoot – fishing spear) includes the following: bells, taps, SHMU, scrapers, etc. Type, model, specifications, date of manufacture, date of revision, and availability of the main consumables of the above elements.

Download Rig Acceptance Checklists

Ultimately, we believe that any drilling engineer or rig drilling supervisor would need a rig audit or acceptance checklist. So, we have gathered a collection of rig inspection checklists according to API and Osha recommendations in the Rig acceptance checklists article.

Good morning sir can you send me a copy of the rig audit acceptance and commission procedure

I will be very thankful to you for your time and consideration