Oil & Gas Directional drilling is the science of directing a wellbore along a predetermined well trajectory to intersect a designated sub-surface target. From its early beginnings in the 1920s, when many regarded it as a “black art”, oilfield directional drilling evolved to the point where we can genuinely regard it as a science, although not always an exact science.

The offshore oil and gas drilling industry is founded on directional drilling. Without directional drilling techniques, producing oil from most offshore fields would not be economical. Improvements in oilfield directional drilling tools and techniques coupled with advances in production techniques have led to a steady increase in the proportion of wells drilled directionally rather than vertically. This trend will continue as the search for oil extends into more hostile and demanding environments.

Causes Of Deviation From The Vertical

The factors affecting the tendency of a drilling bottom hole assembly to drill in a direction other than the existing axis of the well remain the same, whether the deviation is an unwanted problem or deliberate deviation.

Many have observed that a bit is more likely to drill the hole away from its established path under certain conditions.

Mechanical forces affect the behavior of the drilling assembly:

- When using a more flexible drilling BHA type.

- When applying increased weight to the drilling bit.

Various formations act differently on the rock bit:

- When drilling laminated rock, e.g., layers of shale and sandstone, compared with a homogeneous limestone.

- When drilling formations that have certain dip angle and hardness characteristics.

In the hole deviation control article, we have discussed the factors that affect such deviation and the methods of controlling it.

Directional Drilling Applications In Oil & Gas Wells

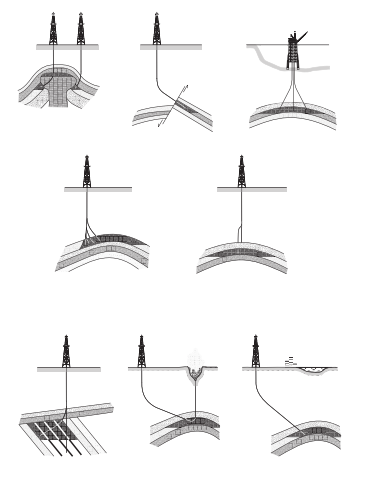

The following text and sketches illustrate the most common applications of directional drilling.

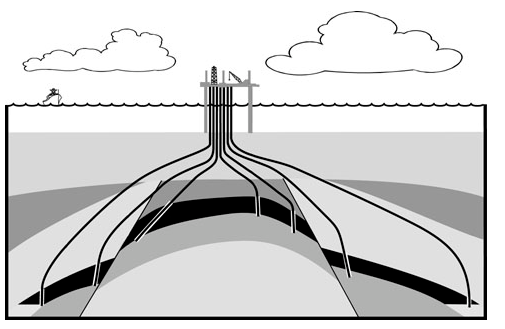

Multiple wells from offshore structures

A widespread application of directional drilling techniques is in oil and gas offshore drilling rigs. Many oil and gas deposits in the Gulf of Mexico, North Sea, and other areas are situated beyond the reach of land-based rigs. To drill a large number of vertical wells from individual platforms is impractical and would be uneconomical. The conventional approach for a giant oilfield is to install a fixed platform (platform rigs) on the seabed, from which we can drill many directional wells. Then, we can carefully space the bottom hole locations of these wells for optimum recovery.

In a conventional development, we cannot drill the wells until installing the platform. This may mean a delay of 2 – 3 years before production can begin. However, we can considerably reduce this delay by pre-drilling some wells through a subsea template during the construction of the platform. These wells are directionally drilled from a semi-submersible rig or jack-up rig and tied back to the platform once installed.

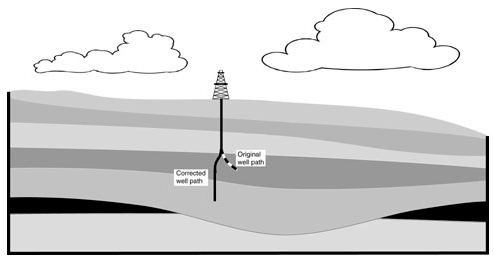

Controlling Vertical Wells

Many oil and gas companies use directional techniques to straighten crooked holes. In other words, when deviation occurs in a well that is supposed to be vertical, various techniques are used to bring the well back to vertical. This was one of the earliest applications of oil and gas directional drilling.

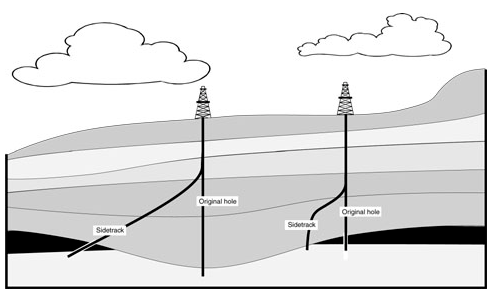

Sidetracking

Sidetracking out of an existing wellbore is another application of directional drilling. This sidetracking may be done to bypass an obstruction (a “fish”) (fishing in drilling) in the original wellbore, to explore the extent of the producing zone in a particular field sector, or to sidetrack a dry hole to a more promising target. Other applications of sidetracking are to access more reservoirs by drilling a horizontal hole section from the existing well bore.

Inaccessible locations

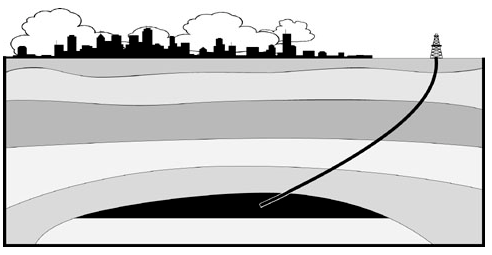

Directional wells are often drilled because the surface location directly above the oil/gas reservoir is inaccessible due to natural or man-made obstacles. Examples include reservoirs under cities, mountains, lakes etc.

Fault Drilling

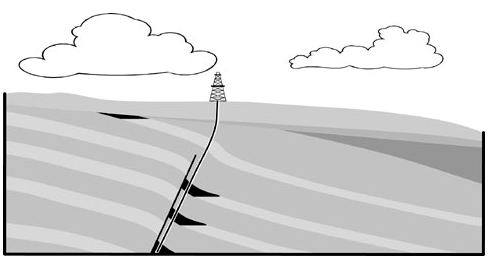

Directional wells can be used to avoid drilling a vertical well through a steeply inclined fault plane which could slip and shear the casing pipe.

In addition, we use it to drain, in one well, a staggered series of small accumulations trapped below a fault. The name of this technique is “fault scooping”.

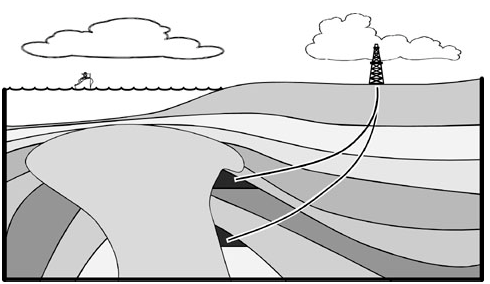

Salt Dome Drilling

Some drilling engineers use directional drilling programs to overcome the problems of salt dome drilling. Instead of drilling through the salt, the well is drilled at one side of the dome and deviated around and underneath the overhanging cap.

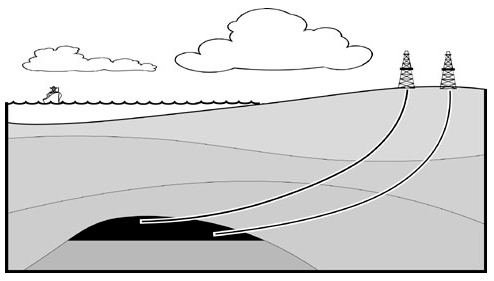

Shoreline Directional Drilling In Oil & Gas.

When a reservoir lies offshore but quite close to land, the most economical way to exploit the reservoir may be to drill directional wells from a land rig types (Drilling Rig Components) on the coast.

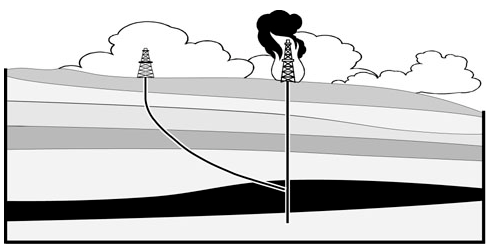

Relief Wells

In addition to the above, we mainly use directional techniques to drill relief wells from a safe distance to “kill” wells flowing out of control (blow-outs).

The relief well(s) is/are designed to enter the reservoir close to the blow-out well for a so-called saturation kill with water or to intersect the blow-out well for a direct kill using high-density drilling fluid (Kill Sheet calculations).

Other Directional Drilling Applications In Oil & Gas

The above are only some of the many applications of directional drilling. Although it is not a new concept, horizontal drilling is the fastest-growing branch of directional drilling, with significant advances in the tools and techniques used. One application specific to horizontal (and almost horizontal) wells is to drill through a shallow reservoir parallel to the bedding plane, thus allowing one well to drain an area requiring several vertical or medium-angle wells.

Horizontal wells also make possible the recovery of liquid hydrocarbons from an interval between an oil-water contact and a gas-oil contact so thin that it could not be produced from a vertical well because of the coning effect.

Well Planning

Many aspects are involved in planning a well, and many individuals from various companies and disciplines are involved in designing various programs for the well (e.g. drilling fluid program, casing design program, drill string design for each section, bit program, etc.). The new engineered approach to well planning means that service contractors become equally involved in areas such as drill string design which are vitally important in planning a deviated well, predominantly horizontal or extended wells.

In the following sections, we shall concentrate on those aspects of well planning that have always been the province of directional drilling companies.

Reference System & Coordinates:

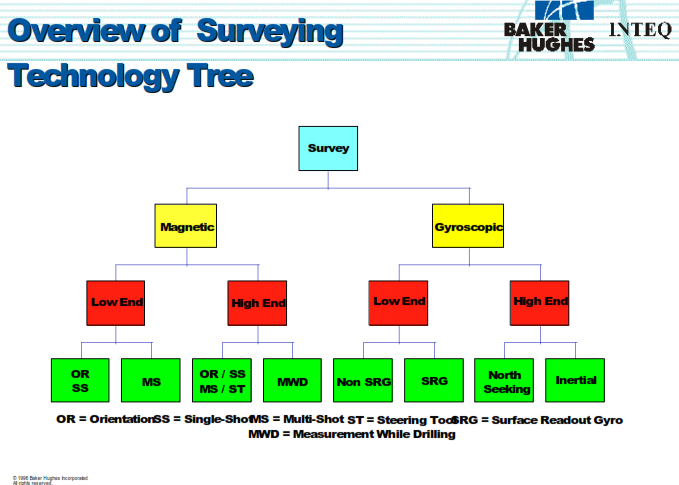

Except for Inertial Navigation Systems, all survey systems measure inclination and azimuth at particular measured depths (depths measured “along hole”). We must tie these measurements to fixed reference systems to calculate and record the borehole course.

Article References & Coordinates In Directional Wells will explain in detail the different coordinates & reference systems that we use in directional drilling.

Planning The Oil & Gas Well Trajectory in Directional Drilling

The well trajectory is a three-dimensional path that a wellbore takes when drilled and is a function of three variables: the inclination, the azimuth, and the build rate. The well trajectory influences many factors, such as wellbore stability, mud transport, fluid flow, and wellbore tortuosity, to name a few. Consequently, the well planner must be familiar with the methods used to calculate the well trajectory.

Nowadays, software programs work on these mathematical equations to solve them and give you the results, but knowing what you have and can get from it is good. Check the complete guide for the well trajectory planning and calculations & Well Profile Types.

Final Steps

To complete the oil and gas directional drilling program, the well planner has to go through the following steps:

Directional Drilling Deflection Tools In Oil & Gas Wells

We can consider many aspects while choosing the applicable Bottom Hole Assembly for the planned directional work. We can say that rig daily cost and formation lithology are the main factors for such selection. Below we have discussed the different Bottom hole assembly types for oilfield directional drilling. But before proceeding with the deflection tools, we recommend reading the following articles:

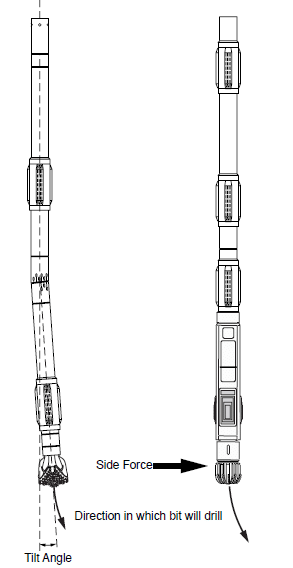

We can use several tools and techniques to change the direction in which a bit will drill. These tools and techniques can change the wellbore’s inclination or the azimuthal direction. All of these tools and techniques work on one of two basic principles.

- Firstly, to introduce a bit tilt angle into the axis of the BHA just above the bit,

- Secondly, to introduce a side force to the bit (See Figure 11).

Introducing a tilt angle or side force to the bit will result in the bit drilling off at an angle to the current trajectory. The significant tools currently used for this purpose are:

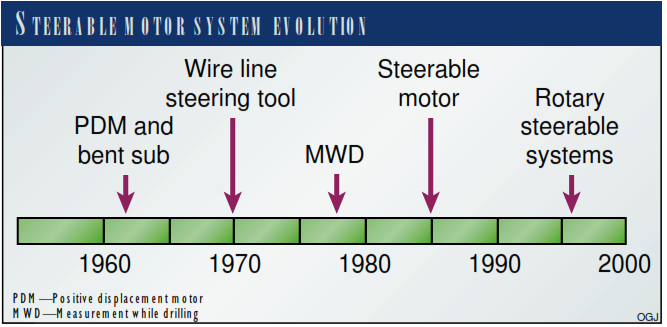

- Bent Sub and Positive Displacement Motor

- Steerable Mud Motors

- Rotary Steerable System

- Directional Rotary Bottom Hole Assemblies (BHA)

- Whipstocks

Directional Drilling Survey In Oil & Gas Wells

When drilling a directional well, the actual trajectory of the well must be regularly checked to ensure that it agrees with the planned trajectory. This is done by surveying the position of the well at regular intervals. These surveys will be taken at very close intervals (30’) in the well’s critical sections (e.g., in the build-up section). While drilling the long tangential section of the well, surveys may only be required every 120′. The surveying program will generally be specified in the drilling program. If it is found that the well is not being drilled along its planned course, a directional orientation tool must be run to bring the well back on course. Generally, the earlier such problems are recognized, the easier they are to be corrected. Surveying, therefore, plays a vital role in oilfield directional drilling.