A pipe sticking mechanism is something that is happening in the hole, which causes the force required to pull string to be greater than the weight plus the expected friction. In addition, the supporting force while running in will be less than the weight minus the expected friction. Sticking mechanisms can act while raising the string, or while lowering it, or both.

A string of tubulars plus the incorporated equipment is subject to the normal laws of physics, including friction. When a drill string is pulled, the force required is the weight (in fluid) plus the friction. When running into the hole, the supporting force equals the weight minus the friction. This is a fact of life and cannot be avoided. It does not mean that frictional forces cannot be controlled to some extent by using a drilling fluid with more or less lubricating properties, but the statement is still true.

Definition

A stuck pipe refers to a situation in oil and gas drilling where the drill String cannot rotate, move up, or down. As we all know, to drill a well, you will need a string to transmit the produced torsion force & load from the surface to the bit. The directional driller and driller direct the well by several parameters: the torque, pulling, and rotating of the drill string. This can result in significant disruptions to drilling operations and can be a costly and time-consuming problem to resolve.

General Pipe Sticking Mechanism

The difference between the actual and expected forces while pulling out is called the overpull; the difference while running in is called the setdown weight.

The overpull and the setdown required to move the string can have any value from zero to (in theory) infinity. If they are zero, the hole is said to be “free”; as they increase, the hole is said to be getting “tight”. Thus, a stuck pipe is not an on/off situation that can be defined in absolute terms. In practice, the pipe is said to be stuck when the force required to move it upwards is greater than the tensile strength of the top joint of the pipe (after applying a safety factor). It is, of course, not necessarily stuck when the weight of the string itself is not sufficient to take it down the hole, as it may still be possible to pull it back out.

If a string sticks while pulled out, lowering it may be possible. In that case, it is free to move up and down through a certain distance, but it is still treated as a stuck pipe because it is recovered using the same techniques. Depending on the sticking mechanism, the pipe can be stuck when pulling out but still be free to rotate. The opposite situation is not feasible.

Pipe Sticking Forces

Pipe stuck may occur during the drilling section, connection time, or any operation at which the Drill String is inside the hole. The stuck happens on Drill String when

BF + FBHA > MOP

Where:

- FBHA: The force exerted by the sticking mechanism on the Bottom Hole Assembly BHA

- BF, background friction is the amount of friction force created by the side force in the well.

- MOP (Maximum Overpull): is the max. Pull that the derrick, hoisting system, or drill Pipe (API drill pipe specs) can handle it will be their lowest value. And always, it is the value related to the drill Pipe.

In other meaning, Drill String got stuck because the force required to move it much bigger than the MOP (Maximum Overpull)you can reach.

Consequences of Stuck Pipe

A stuck pipe can cause the breaking or loss of a part of the drill string in the hole. Its result is costly. They include:

- Drilling time lost (working on the stuck).

- Cost (check also drilling cost per foot) & time spent on working on the fish (fishing operations) (to retrieve the lost part of the Drill String or the BHA.

- Leave the fish in the hole, as retrieving it is difficult or costly.

- Perform a sidetracking well, which is also a waste of time and cost.

A few concerns must be taken into consideration when working on a stuck:

- Formation pressure

- Drilling mud types

- The Time (as you must understand that as time runs while working stuck, the situation becomes challenging to free the stuck).

Pipe Sticking Categories

During drilling, three categories of sticking mechanisms related to the hole will be considered in turn in the following Topic. These are caused by:

- Hole geometry or Mechanical Sticking

- Formation (lithological) characteristics

- Differential sticking.

There are also three categories of sticking mechanisms that relate more to operating practices and can equally well, or only, occur inside the casing and can occur during workovers as well as during drilling. These come under the general categories of:

- Equipment geometry

- Solids other than drilled cuttings

- Corrosion

- Collapsed Casing

Hole Geometry Or Mechanical Pipe Sticking

Key Seating

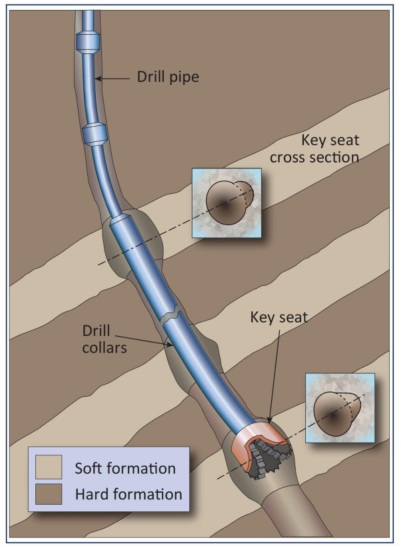

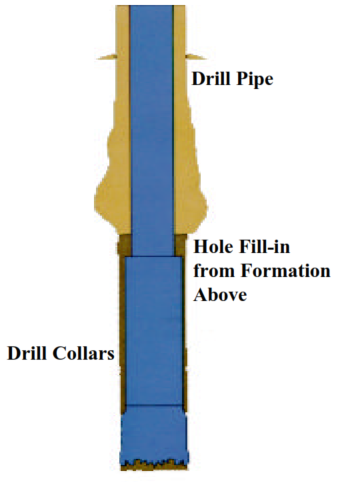

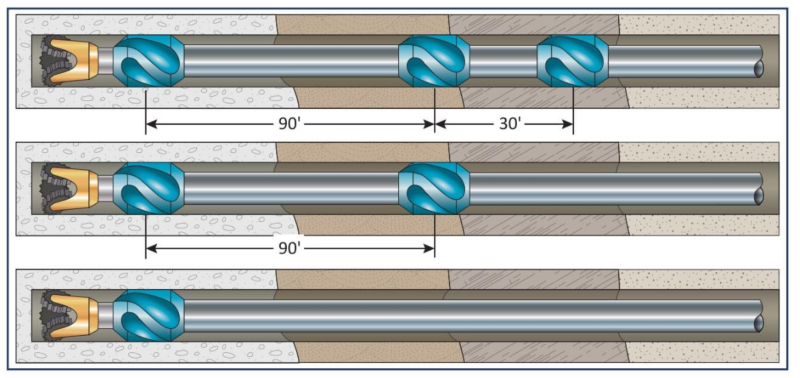

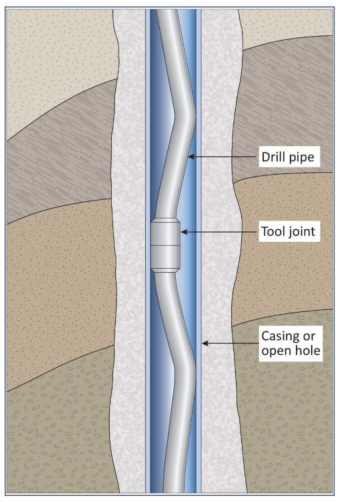

A key seat results when a drill pipe under tension wears a slot into the wall of the hole during drilling and pipe tripping operations (Figure 1). It often occurs when drilling a directional well.

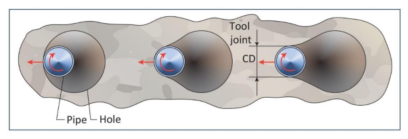

The slot diameter is usually the same as the diameter of the drill pipe tool joints. The drill collars are, therefore, most likely to get jammed in a key seat when pulling out of the hole (Figure 2).

It is often possible to move the drill pipe up and down through the key seat but still be unable to pull the drill collars through it. When drill collars are pulled against a known key seat, great care must be taken; otherwise, they may be pulled so tight into the key seat that the string becomes stuck. You might be interested in reading the key seat wipers article.

Check the complete article about the Key Seating Problem.

Well Curvature (Doglegs)

A stiff or packed-hole BHA type can get stuck when tripping through a hole drilled with a flexible or bent sub assembly. The lateral forces required to bend the assembly to fit the curves in the well means that high forces are generated between the string and the borehole wall, which in turn means that the friction forces are high. While running in these forces may increase until the friction is sufficient to support the weight of the string, at which stage no more progress is possible. The driller should have noticed the situation long before that happened, as the hook load would have decreased with depth instead of increasing for some time.

This situation is more complicated than the previous paragraph may seem to indicate. While running in the weight of the upper part of the string will tend to buckle the string if the bottom end meets resistance. Thus, the weight of the string decreases the bending force which has to be supplied by the borehole wall. While pulling out through a curve, however, the tension in the string has a component that increases the lateral load at the point of contact and thus increases the friction forces. In other words, if the string seems lighter while running in, it may be impossible to pull out.

The only way of preventing this is to be aware of the problem and avoid running a stiff assembly directly after a flexible one. Several runs with reamers on a string with intermediate flexibility are required to wear off the “corners” and increase the hole’s curvature radius.

This is, of course, one of the reasons for avoiding unplanned dogleg.

Ledges

Suppose a formation consists of bands of a hard competent lithology embedded in a soft or unstable material. In that case, the latter will tend to wash away, leaving ledges of hard material jutting out into the borehole. There will then be a tendency for the stabilizers to catch under the ledge while pulling out. Depending on the geometrical relationships, it can be difficult to get past such a ledge.

Ledges may also cause problems while running in, but if the bit is above them, they can be reamed, or the protruding part knocked off.

Preventive measures are aimed at reducing washouts by the proper choice of drilling fluid type, controlling its properties, and optimizing the pumping rate. Read more about this stuck mechanism at Ledges & Doglegs article.

Jamming A New Bit & Undergauge Hole

An undergauge hole is a section of a hole with a smaller diameter than the diameter of the new bit used to drill ahead. The most common cause of under-gauged holes is gauge wear on the previous bit run. (Other, more troublesome causes are described below under “geological factors.”)

Hard abrasive formations often wear down the outer diameter of the bit and stabilizers. After replacing the worn bit with a new one, the latter may become stuck while running near the bottom part of the hole due to a reduced hole diameter.

This bit jamming can be prevented by carefully inspecting the OD of the old bit pulled (Bit Dull Grading Procedure) and reaming the suspected under-gauged section with the new bit. You may want to read more about this stuck mechanism in the undergauge hole article.

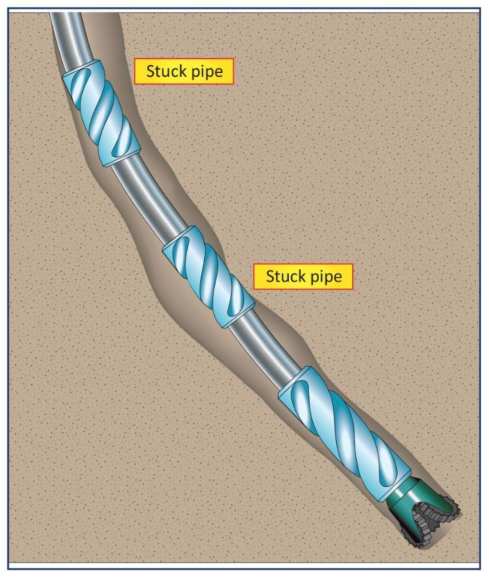

Pack-Off / Bridge Stuck Pipe

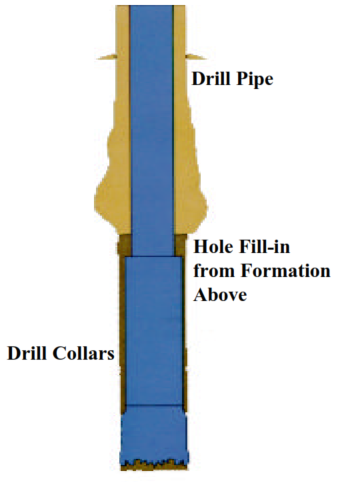

Sometimes, during drilling operations, the Hole Bridge can occur. This happens when large pieces of formation, cement, or debris settle around the Drill String, which restricts circulation and prevents any movement of the string. On the other hand, smaller pieces of formation, cement, or debris can cause the Drilling Pack Off, which also stops circulation and prevents any movement of the string.

A sloughing hole usually occurs immediately below a cavity. The most common cause is very poor filter cake across an unstable zone. A warning sign during drilling is hole fill during connections or trips. An indication of a sloughing hole sticking is the pipe being stuck and the hole being packed off. Circulation is greatly reduced or impossible.

Bridging can occur in a Blowout situation. In addition, there will be more than one stuck interval. A free point indicator tool will only located at the top of the stuck drill string. A pipe recovery log and a noise/temperature survey are usually required to gather enough information to determine the fishing tools & procedure.

Formation Related – Geological Factors

Plastic Formations

In addition to a worn bit, an undergauge hole may also be caused by a plastic formation. After being penetrated by the bit with a fluid, giving a hydrostatic pressure less than the overburden, which is the usual pressure of the plastic formation, this formation deforms, causing the hole to close. One of the formations that most often causes such a situation is moving salt.

The only preventive measure is to use a drilling fluid dense enough to give overburden pressure at the depth of the salt. This will usually be impossible due to the risk of creating fractures elsewhere in the hole. In that case, the drilling fluid density should be kept as high as feasible, as the flow rate of the salt is proportional to the pressure difference.

If the pipe becomes stuck, the solution (!) is simple – a pill of fresh water. If this is done, the effect of introducing a light fluid on well control aspects has to be considered.

Shales & Stuck Pipe

Shale formations vary considerably in their behavior.

Sometimes, they behave plastically, as described above. However, the chemical reactions of the clay minerals with the drilling fluid usually cause hole problems and result in stuck pipe problems. Once penetrated, there is usually a critical time when a shale remains acceptably stable before its reactions generate hole problems. It may vary from one or two hours to several days. The time required for such deterioration and the degree of instability are related to many complex factors:

- The degree of compaction of the shale.

- The moisture content of the shale.

- The extent to which water from the drilling fluid can invade the formation.

- The angle at which the bedding planes are penetrated.

Borehole shale instability can often be prevented by raising the drilling fluid density, using inhibitive muds, minimizing the open hole time, and/or good hole cleaning. Analysis of the data will usually indicate which is the best solution.

Shales Groups

Shales can be considered in different groups: “wet”, “swelling”, “brittle”, “overpressured”, “undercompacted” etc.

- Wet or plastic shale (“Gumbo”): This group includes soft unconsolidated clay and shales with a porosity up to 30%. Hole problems will arise from the plasticity when large volumes of cuttings are produced due to high penetration rates, which clog together on their way to the surface. They develop clay balls that plug the flow lines.

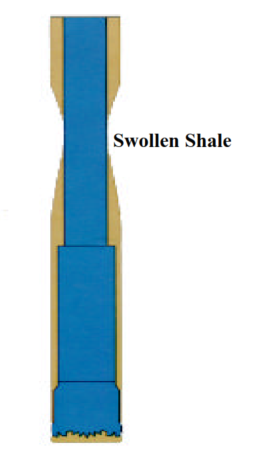

- Swelling shale: These contain an appreciable amount of bentonitic clay, which reacts freely with the drilling fluid filtrate. They hydrate, swell, and invade the hole. This leads to a tight hole, particularly when first drilled. Repeated reaming during subsequent round trips is usually needed.

- Brittle or sloughing shale: When the rock is penetrated, substantial support by the overburden pressure is removed as a result of the hole, and this causes the stresses to become unbalanced. If, in addition, a shale is overpressured and has a high pore pressure, the formation at the wall of the hole will likely break away and generate large volumes of shale slivers (cavings).

Fractured and Faulted Formations

In areas close to fault zones or where folding has been severe, the formations penetrated by the bit may contain a multitude of very small slip planes, which make the rock incompetent. After the drill has passed through such a formation, it will start crumbling because support has been removed, and blocks may fall into the borehole and jam the bit.

Highly Stressed Formations

The less competent formations will have yielded plastically in areas with much geological activity but where faulting has not relieved the stresses. However, the more rigid formations will have yielded elastically, and when penetrated by the bit, they may still have high stresses locked in. Drilling the hole relieves that stress in a non-uniform manner, and the borehole wall may fail, allowing large fragments to fall into the well and jam the string. This type of problem is typical of igneous rocks such as sills, which have been injected in an initially horizontal sheet that has subsequently been folded to a lesser or greater degree. This is one of the more serious types of problem, and the existence of such an overstressed formation can, in fact, make a well undrillable.

Settled Cuttings & Cavings

It is possible for cuttings and cavings to settle around the bit and to pack tight to such a degree that the bit cannot be pulled through them. Under normal circumstances, this will not result in the pipe becoming stuck for any length of time or a fishing job, as the solids can be loosened and washed away by normal or high-rate circulation. If, however, there is a weak formation below the bit, the situation could be troublesome.

This can happen while drilling any well if:

- There is a total mud pump failure while drilling.

- The solids laden mud is not circulated out before a trip.

If the well is not properly circulated and cleaned of cuttings, the cuttings may accumulate and settle around the Drill String, particularly the Bottom Hole Assembly (BHA). This is due to the small clearance between the BHA and the hole, which may lead to a pipe stuck in the Drill Collar. This stuck problem is usually caused by inadequate hole cleaning.

The situation can also arise during operations where nothing goes wrong and good practices are used. In these cases, it is a question of hole cleaning.

Differential Pipe Sticking

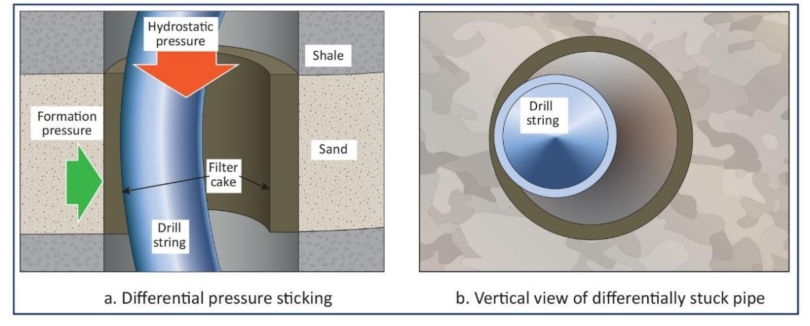

The vast majority of stuck pipe problems arise from differential pressure. This condition occurs in the open hole when the string comes in contact with a permeable formation, having a pore pressure less than the drilling fluid head. The string is then held in place by this differential pressure while the other side remains subjected to the hydrostatic pressure of the drilling fluid. It can also happen when the drilling fluid filtrate invades the permeable formation, causing it to swell (shale swelling) and adhere to the drill pipe.

Differential pressure sticking can, therefore, be defined as the force that holds the pipe against the wall of the hole due to the differential between formation pressure and hydrostatic pressure (see the accompanying Figure).

Note that drilling fluid density does not have to be high for differential sticking to occur as long as the hydrostatic pressure is significantly higher than the formation pore pressure.

To summarise, for differential sticking to occur, the following criteria are required:

- Hydrostatic pressure must exceed formation pressure.

- A zone of permeability must exist over which a thick filter cake has been deposited.

- There must be contact between the pipe and the filter cake.

Equipment Geometry

Stiff Assemblies

The drill string can become stuck if there is a significant change of BHA when drilling a directional well conventionally. Rotary BHAs designed to build inclination are usually quite flexible to allow drill collar sag to tilt the bit around the near-bit stabilizer. BHA types designed to hold angles are usually much stiffer with less spacing between the stabilizers.

The new assembly can become stuck in the hole if the build section has excessive dog legs. The drill string will suddenly take the weight when running into a hole due to three-point contact between the BHA and the borehole wall. Great care has to be taken as the shape of the string will change in the hole when picking up and making the situation worse. Indeed, once the string starts to take weight, it may only be able to make progress downwards.

The circulation is unlikely to be restricted. The resolution is to jar in the opposite direction to movement, taking care not to slack off too much weight in the first place. This type of sticking is best avoided by controlling the build rates and dogleg severity with a limber assembly and minimizing changes to the BHA configuration. If weight is taken when running in the hole with a stiffer BHA, reaming should be conducted with high RPM and very limited WOB. The string should be picked up regularly to ensure that the pipe is free

Crooked Or Bent Pipe

This situation usually occurs after a string of pipe (tubing or drill pipe) has been dropped. It can also be caused by continuous working down weight on a stuck string. In such a situation, the friction may become so excessive that the maximum allowable surface pull cannot move the string.

The pipe may then have to be recovered in sections.

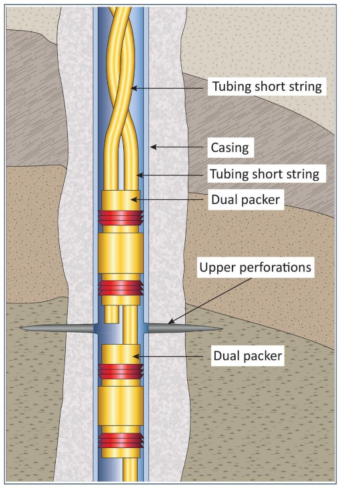

Strings Wrapped Round Each Other

This situation is illustrated in Figure 10. It would normally only be encountered during the workover of a dually completed production well.

SOLIDS (OTHER THAN CUTTINGS)

Settling Out Of Sand & Barite

Sand settling is a condition that often occurs in producing wells, although drill pipe in open hole can also become sand-stuck. Sanding in of tubing in cased holes may be caused by sand production or a hole in the casing. These conditions allow sand to settle in the annulus and cause the pipe to become sanded in.

In the case of drill pipe, while cleaning out the well with fluid with low carrying capacities, sand circulated up the hole can settle out. Sand-stuck drill pipe is treated in the same manner as sand-stuck tubing, and washing over is the commonly applied technique.

Barite settling is caused by the deterioration of the drilling fluid in the annulus. In some holes, temperature could affect drilling fluid additives, causing them to degrade and allow the barytes to settle out.

In the open hole, contaminants may enter the drilling fluid and alter mud properties. Common contaminants are the formation water, salt, and gases. These conditions may cause drilling fluid deterioration, allowing barites to settle out and resulting in a stuck string.

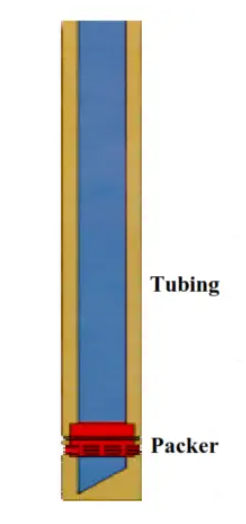

Settling Out Of Fine Solids

This is a cause of stuck packers during workovers. During the completion of a well, it is circulated to an appropriate clear fluid before setting the well packer(s) or perforating. This is referred to as a packer fluid. The objective is to avoid plugging the perforations with solids from the drilling fluid at the moment of perforation (for this reason, perforating is normally done in an underbalanced situation) and to avoid drilling fluid solids settling on top of the packer during a long period of production.

It is, however, extremely difficult to filter all the fine particles from a fluid under the operating conditions of a drilling rig, and even if they look clear to the eye, most packer fluids will still contain microscopic particles. During the course of years these will settle onto the topmost packer. It needs surprisingly little sediment to stick a packer – a few inches is sufficient, and considering that it could be settling out of a column several thousand feet long, the critical initial concentration is not very high.

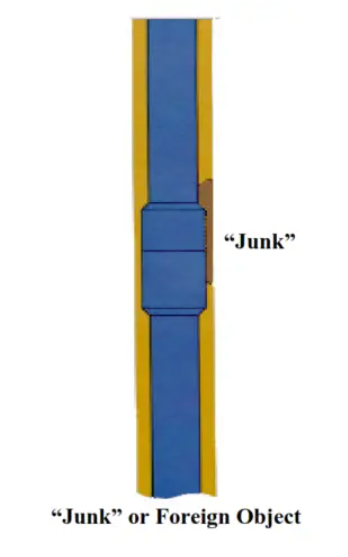

Junk In The Hole

Junk dropped into the hole may wedge at the bit, the top of a stabilizer, the top of the drill collars, a tool joint, or any other location where falling debris would encounter a decrease in the size of the annulus. Typically, this would not be noticed until an attempt is made to lift the string, either to add a single or to trip out of the hole. At this time, the string would become jammed. The string is often free to move down but cannot be raised. Read more about sticking due to junk.

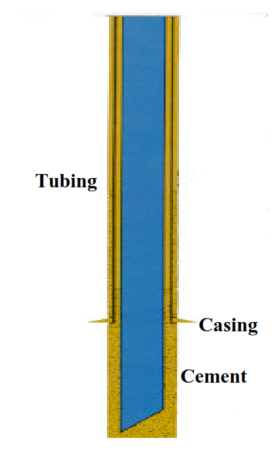

Cement

Cement can stick the pipe in two different ways.

The cement around the shoe of a string of casing pipe can break up due to the impact of the drill pipe against the casing during subsequent drilling. It can then fall into the hole in blocks and jam the bit or on top of a stabilizer. Such blocks may be difficult to dislodge by circulation. This is not a common problem.

A more serious situation is that of cement setting around the drill pipe. This can be caused by:

- The flash setting of the cement when setting a cement plug.

- A leak in a string while setting a plug or cementing a string of casing through a drill pipe and a stabbed-in stinger.

- Human error, such as miscalculation of displacement time or failure to add CMT retarders when setting a plug.

- Embedding the drill pipe in unset cement when running into the hole

It can also result from an emergency action to contain a blow-out or stop lost circulation.

In this case, fishing is not feasible after cutting and recovering the upper section of the cemented-in pipe. Furthermore, in an open hole, the best option is usually to sidetrack. In a cased hole, cutting a window and sidetracking is an option, but if necessary for casing design considerations, or if the top of the cemented section is not far above the casing shoe, the string plus cement could be milled down to just below the shoe. This operation goes surprisingly quickly – several feet per hour is a normal rate.

Corrosion

Well Packer

If a packer has been set in an oxygen-rich packer fluid, it may corrode during the course of years to such an extent that the slips cannot be released during a workover, and it cannot be pulled free. It then has to follow the milling procedure in drilling.

Production Tubing

If a well produces a corrosive fluid for a long period, which could be as short as a few months in severe cases, the tubing may well be significantly weaker than in its new state. During a workover, the tubing may part before the bottom hole assembly can be freed. By definition, the bottom assembly is then stuck in the hole and has to be recovered using normal fishing techniques.

Open Hole – You have a stuck pipe! – What’s next?

Whenever the pipe becomes stuck, always calculate the estimated depth at which the pipe is stuck by measuring the stretch in the stuck pipe at a given pullover string weight. The common stretch formula is as follows: 2208.5 X nominal weight of the tube = the overpull necessary to induce 3 ½” stretch per 1,000’ of free pipe.

Stuck Pipe First Action

Two questions must be answered to correctly analyze which sticking condition applies to your current situation. The questions are:

- Was the pipe moving when it became stuck?

- Are the hydraulic properties of the well the same or different than before the pipe became stuck?

Was the pipe moving when it became stuck? YES or NO

- NO – There is no change in hydraulic properties. – Differential Sticking

- NO – With a change in hydraulic properties ( Reduced Flow, Higher Pressures, or both) – Sloughing Hole

- YES – What direction? – UP- Keyseat or Undergauge Hole or Differential Sticking

- YES – What direction? – DOWN – Undergauge Hole or Differential Sticking

- YES – What direction? – Rotating – There is no change in hydraulic properties. – – Differential Sticking

Are your hydraulic properties the same or different than before the pipe became stuck? YES or NO

- YES – Differential or Keyseat or Mechanical Sticking

- NO – Well Bore Geometry (Sloughing Hole or Undergauge Hole)

Jarring on Stuck Pipe

- If the pipe became stuck moving up — Jar Down.

- If the pipe became stuck moving down — Jar Up.

- If the pipe was not moving when it became stuck — Apply torque and jar down unless the bit is on the bottom — then jarring up is the only option.

Turn It To A Fish

If a string of tubular is stuck and cannot be freed by pulling, rotating, and/or pumping, the next step is to turn the lower part of the string into a fish by either backing it off (i.e., unscrewing it) or cutting it just above the section which is stuck.

The initial reason for doing this is because of the elasticity of the string. Even though the string may be stuck to a steady pull, it may be possible to move it (either up past an obstruction or down until it is free again) by delivering a series of impacts – a procedure called jarring. Because of the elasticity of the string, an impact delivered at the surface would be ineffective at depth, and an impact downwards would buckle the string, probably making the situation even worse.

The closer the impact is to the stuck point, the more effective it will be, and for that reason, the string is backed off or cut, and a fishing string connected to it with special tools, including a jar – or hammer – at the lower end. In this case, the elasticity of the fishing string is put to good use because the impact is delivered by storing energy in the string by stretching it and then transferring the stored energy to the hammer.

If the string cannot be moved by jarring it, a possible option is to grind it away using a mill tool. In a milling operation, it is evidently advantageous to minimize the length of pipe to be milled – another reason for backing off/cutting the string as close as possible to the stuck point.

Pipe Sticking Prevention Measures

Stuck pipe is a good example of the proverb that prevention is “better than cure.” The recovery from a stuck pipe situation can be very time-consuming, hence expensive, and, at the limit, may lead to the loss of the well with the resultant necessity to redrill it. It may alternatively result in what, in the long term, maybe even worse – a poor quality well. On the other hand, it only requires a short time during the preparation phase of a given well to consider how such situations could arise and to design it so that those situations are avoided or at least minimized. The routine application of normal good practice while drilling the well also goes a long way towards avoiding problems.

To prevent or mitigate stuck pipe incidents, the following measures can be taken:

- Proper wellbore planning: Adequate wellbore planning, including wellbore stability analysis, can help identify and avoid potential sticking points.

- Proper drilling fluid selection: Proper selection and maintenance of drilling fluids can help minimize the risk of differential sticking.

- Proper drilling practices: Following good drilling practices, such as maintaining proper weight on bit, controlling drilling fluid properties, and monitoring wellbore conditions, can help prevent the problem.

- Utilizing stuck pipe prevention tools: Various technologies and tools, such as drilling jars and downhole sensors, are available to detect and prevent such incidents.